Meter/mix/dispense machines: Doubling down on control

The latest equipment solutions deliver lower costs, faster cycle times and better part properties.

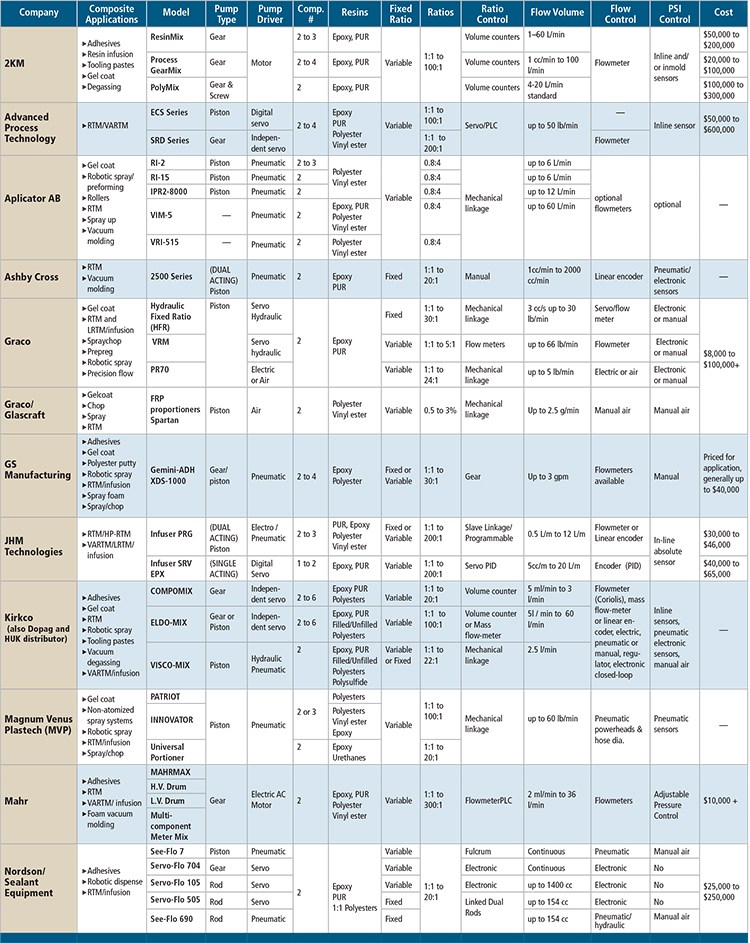

The need to meter, mix and then dispense lubricants, foams, paints, coatings and other fluid products has spawned a huge industry. In fact, equipment aimed at the composites industry is a very small part of the total meter/mix/dispense (MMD) market. That said, MMD has become a necessity throughout the business of composites fabrication. Molders use MMD equipment to supply resin systems to gel-coating and sprayup equipment, to inject them into pultrusion dies, to impregnate dry fiber in the filament winding process and to wet out layups and preforms in closed molding processes. MMD also plays a key part in the production of many raw fibers and base resins used in composites. Polymers must be metered and mixed before they can be spun into a fiber, and resin manufacturers must meter and mix resins with additives. This highlights a recent trend in materials suppliers using MMD machines to avoid the cost and inflexibility of batch processing, both in mixing powdered additives (e.g., pigments, fire retardants and glass microspheres) and in prepregging. One of the biggest trends, however, is the use of MMD and robotics in adhesive application, in search of the perfect bondline, as OEMs move away from mechanical fasteners in search of greater speed and reduced cost.

MMD basics

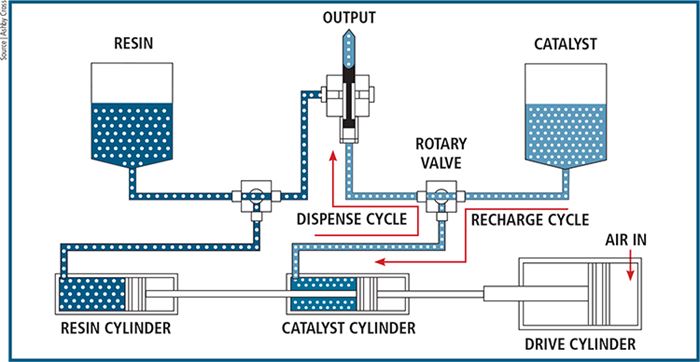

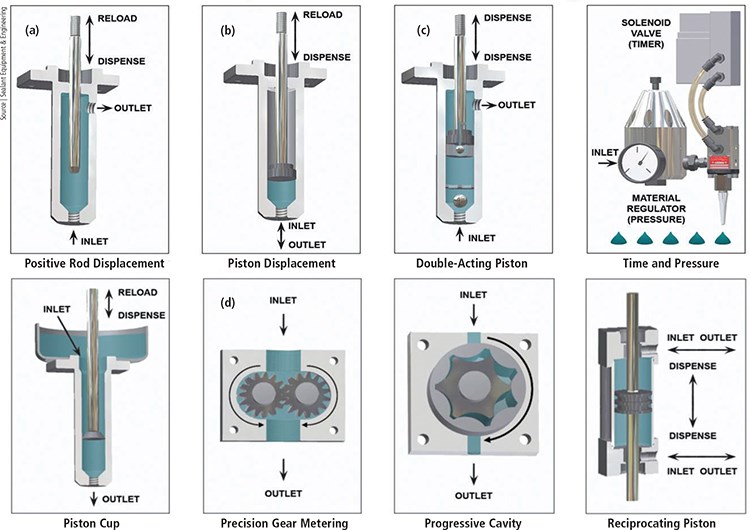

Meter/mix/dispense MMD systems are used with multicomponent resin systems. Two-component thermosets predominate: Part A (the resin) and part B (hardener for epoxies or catalyst for styrenated resins). That said, systems that require up to six components — pigments, fire retardants and other additives — are not uncommon. But all MMD systems perform essentially the same function: They meter out precise amounts of each component, mix them, and then dispense them via positive displacement, meaning material is dispensed either by moving a piston or rod or by rotating an auger or gear, onto a surface or into a mold (see the opening illustration, at left).

MMD equipment can be relatively simple. For example, in a fixed-mix-ratio system, the metered volume may be determined by the displacement of the cylinder used for each component. The cylinders are mechanically linked and actuated by a pneumatic drive, with discrete volumes dispensed one at a time

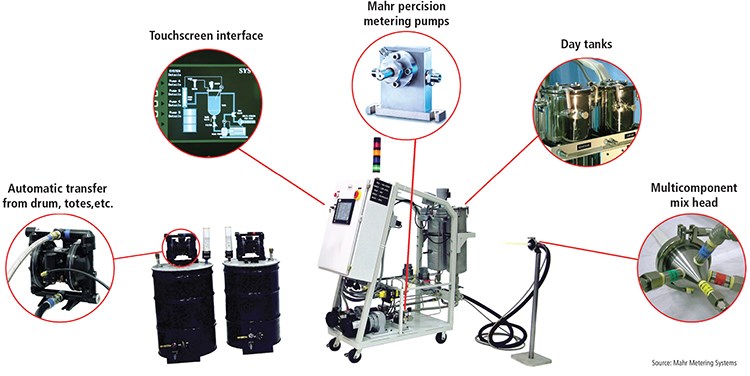

More complex systems, however, can mix three or four components, and do so at variable mix ratios that can range as widely as 1:1 to 100:1. They may also draw components from 55-gal (208-liter) tanks or intermediate bulk containers (IBCs), also called “totes,” which commonly hold 275 or 330 gallons (1,041 or 1,249 liters). Material also can be drawn into pressure vessels. For example, 2KM North America Inc. (Worcestershire, U.K.) lists 45-liter to 10,000-liter (12-gal to 2,642-gal) capacity pressure vessels as material feed options for its Process GearMix 520 and 720 machines. Onboard tanks are also an option, ranging in size from 1 liter (0.3 gal) for small R&D units to 60 liters (16 gal) and larger. These containers can be independently temperature controlled and vacuum degassed, and also can incorporate agitation to ensure homogenization.

More complex systems feature precision gear pumps or piston pumps that use electronic linear encoders (piston pumps only) and/or mass flowmeters as part of a closed feedback loop with a programmable logic controller (PLC) to ensure mix accuracy of ±1 to ±2 percent. They maintain precise flow rate and pressure as they dispense material. Typically, their pumps are digitally slaved, rather than mechanically linked, to increase mix-ratio accuracy and can provide either metered shots or a continuous flow of material.

Most MMD control software not only stores hundreds of process recipes, but might also provide historical data tracking and communicate with the manufacturer’s computer network as well as other equipment, such as a heated press. Accordingly, the cost of MMD systems can range from less than $10,000 to $600,000.

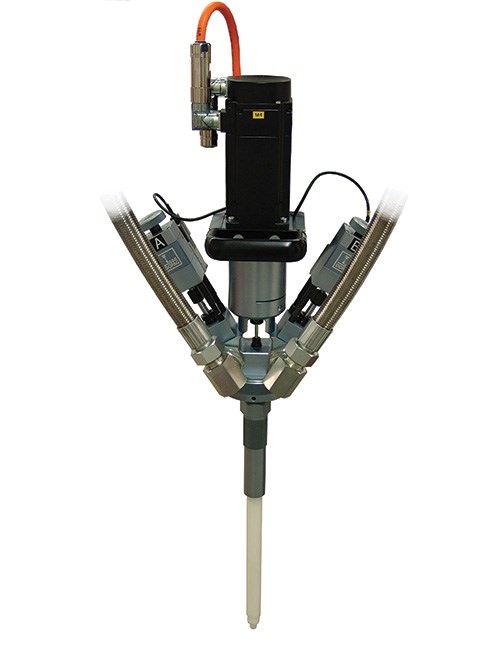

Once the components are metered, they can be combined with one of three mixers. Dynamic mixers have a rotating blade inside a chamber and reportedly give the most complete mixing, but may require purging with solvent after process completion to expel residual mixed material. Static mixers feature nozzles that have no moving parts. Instead, their convoluted interior shapes divide and blend resin components thoroughly as they pass through. There are also removable types, inserted into pipes and hoses (see “In-line static mixers," at the end of this article or click on its title under "Editors Picks," at top right). Static-dynamic mixers are similar to static mixers but have a rotating element for hard-to-mix materials (see sixth image down at left), combining the higher mix energy of dynamic mixers with the disposability of static mixheads.

Which mixhead technology is most appropriate? That depends on the user’s operations. According to Mahr Metering Systems Corp. (Charlotte, N.C.) president Mark Cauthen, “Customers typically buy one MMD machine for each type of chemistry they process,” noting that otherwise, much time and expense is consumed in cleaning machinery: “If they want to use the same machine and change from a two-part to a three-part system or use different colors or additives, they must purge in between.” Although purging can be an automated function, added into the stored process recipes, Cauthen cautions, “You have to have a way to get rid of the purged material, so this has issues with solvents and EPA [U.S. Environmental Protection Agency] compliance.” Disposable static mixers have become very popular, according to Kirkco-Dopag (Monroe, N.C.) president Scott Kirkpatrick. “You take the tube off and throw it away.” In general, he notes, industry prefers solvent-free equipment, and adds that disposables are an inexpensive ($5 to $6) alternative.

Which pump is best?

MMD suppliers differ on the subject of what technology performs best. Many offer multiple types and tailor systems to customer’s needs. Graco Inc. (Canton, Ohio), for example, uses piston pumps (see b, in pump-type diagram, fifth image down, at left) on its MMD equipment for composites. “A gear pump [d] has a limited operating range for providing a good flow rate,” claims director of application development, Mac Larsen. “The flow rate usually varies with infusion and RTM, but if too slow, then pumping is inefficient. Here is where piston pumps are better, more suited to a wider range of injection rates and to maintaining constant pressure.” Larsen claims piston pumps fare better with fillers or particulates, “Gear pumps become too challenging to maintain when using abrasive additives.” But Mahr’s Cauthen takes a different view: “Gear pumps have been around for 100 years,” he maintains. “They offer very steady flow, are made to very tight tolerances using high tool steel and can typically handle temperatures up to 700°F/371°C. Piston pumps have seals and O-rings.” Cauthen claims gear pumps offer a simpler, more compact design, with no O-rings or seals that wear, and thus, part replacement and maintenance are reduced. “Gear pumps are very reliable, with no pulsation versus piston pumps,”adds Gary Smith, Jr., vice president at GS Manufacturing (Costa Mesa, Calif.). Cauthen also points out that for filled resins, gear pumps can use different gear profiles and designs — for example, helical gears. “If you know that the customer will be processing filled material, you can design that into the system,” he says, but adds a caveat: “You’re limited to 40 percent filler by volume most of the time.” Smith adds, “We work with our gear pump suppliers to determine the correct specifications to accommodate fillers. More often than not, piston pumps have a hard time with heavily filled materials, too. The packings, a type of seal, will go out very quickly, which becomes a maintenance problem.”

Piston pump proponents counter that for abrasion and wear from fillers, the answer could be a “ceramic pump,” so called because it features ceramic-coated steel in place of bare metal for the piston and sleeve. The ceramic coating has a Mohs scale hardness of 9 — higher than silica, the raw material for most fillers. Accordingly, the pump surfaces exhibit significantly better abrasion resistance, but are also more expensive. Graco’s Larsen notes, “There are other metal surface treatments that offer similar performance.”

Nordson Sealant Equipment (Westlake, Ohio) prefers positive rod displacement (see opening illutration) for metering filled resins, claiming that it exhibits the least amount of friction and wear and the most accuracy in dispensed volume and mix ratio. Nordson marketing manager, David Mandeville says that in gear pump and piston pump systems “as soon as even a small amount of wear occurs, the mix ratio accuracy can suffer.”

Closed molding: Flow vs. pressure

When MMD is used in composites molding processes that involve resin injection or infusion, John Moore, president of JHM Technologies Inc. (Fenton, Mich.), points out that the MMD supplier must focus not only on the MMD componentry but also on the details of controlling the whole infusion/injection molding process: “Whether you use a gear or piston pump is not as important as maintaining the resin flow front through the volume of the mold.” Moore and other suppliers say the accuracy with which the MMD equipment dispenses material depends on the ability to balance the flow rate and the pressure in the mold.

One way to achieve this balance is by using flowmeters. In the same way that a car’s cruise control speeds up or slows down its motor to maintain overall vehicle speed, flowmeters are used to control the flow coming out of metering pumps. According to Hap Phillips, director of technical sales for Advanced Process Technology (APT, Middlesex, N.J.), “Even very accurate rotary gear metering pumps will slip when encountering back pressure as the mold fills with resin. Mass flowmeters sense the flow exiting each pump and, via the PLC, servo drive and rotary servo motor, increase the speed to overcome mold back pressure and push resin into the mold, or decrease the speed to prevent overpressuring of the mold. It does this for each of the components being mixed, continuously adjusting to keep the mix ratio intact.”

Similarly, linear encoders measure the distance pistons or rods move — there can be up to 1,200 scale divisions per inch, providing very accurate output. The devices feed data back to the machine controller, which calculates how much material has been dispensed.

“With RTM,” illustrates Graco’s Larsen, “you want controlled flow, but also the ability to limit pressure. If you continue at a constant pressure toward the end of filling a mold, you can build up too much [pressure] and separate the tool.” Larsen says that Graco HFR (hydraulic, fixed-ratio) systems are programmable for constant flow rate or constant pressure. Larsen explains that with HFR equipment, either flow or pressure can be the primary control, while the other is monitored and kept below a critical limit. For closed molding equipment supplier Magnum Venus Products (MVP, Clearwater, Fla.), however, the solution is its mold pressure guard, a feature incorporated into its INNOVATOR MMD machine. Designed for light resin transfer molding (LRTM) and vacuum-assisted RTM (VARTM), it features entirely pneumatic operation, with a control box and stroke counter. MVP’s Jeff Austad, VP of sales and distribution, describes the guard’s function: “At about 75 percent of the way to filling the mold, the injection pressure and the pressure at the resin flow front are very different. INNOVATOR uses a pneumatic sensor in the LRTM mold and/or vacuum bag to sense the inmold pressure and communicate back to the machine control to slow the pump, shutting the flow valve and stopping the pump, if required.”

Most MMD suppliers, in fact, can design-in this type of emergency shut-off as well as alarms that indicate when pressure is too high or too low. All of this can be set as needed and settings can be stored in each process recipe.

Moore at JHM Technologies explains that the injection process also can be defined in discrete steps. For example, an initially high flow rate can be followed by three to four reductions. APTs Phillips describes a similar capability with his company’s SRD-series equipment. “You can begin at a continuous flow rate,” he notes, “but then switch over to resin being drawn in with vacuum while maintaining the mold at a certain pressure, utilizing pressure transducers in the material lines. The machine will sense when the mold hits the operator-set threshold pressure and will automatically change pump speeds to control flow to maintain that pressure.” He adds that the operator may want to vary that pressure if, for example, a mold features large, open sections and more closed, complex geometries. “The flow would be fast at first, but then slow as the mold cavity gets tighter,” Phillips explains. He adds that on programmable MMD systems the operator can vary the pressure and also add that variation into the process recipe.

Moore cautions, however, that a thorough understanding of the process is required, recalling by way of illustration a mass-transit part made using LRTM and JHM’s Infuser PRG equipment: Mold temperature was controlled through circulating heated water, and although resin temperature, flow rate, mix ratio and pressure were maintained by the MMD equipment, the pressure during processing began to rise 0.2 bar (2.2 psi) as mold fill neared completion. In this case, the final pressure increase was due to the resin cure kinetics, with the resin just starting to cure as the mold was about to vent. Adjustments were made to the programmed catalyst levels via the MMD equipment and later runs programmed for constant pressure increase in the same final stage of mold fill produced void-free parts with excellent finish on both A and B sides. “The project engineer was amazed at how the entire laminate was influenced by subtle changes in the flow,” Moore recalls, noting that he also “would not have known what was causing the defects without the precise flow controls and feedback.”

JHM goes one step further: A simple, low-cost RFID tag can be affixed to each mold. A scanner linked to the injection system reads the tags, enabling the system’s program software to automatically call up the injection recipe. “The problem with having an operator set a stroke counter is that there are so many variables that can cause that setting to be incorrect, resulting in overfilled or underfilled molds and defective parts.”

Automation in prepregging

Mark Cauthen at Mahr says that meter/mix on demand is new to prepregging, but growing quickly. When prepreggers apply a thin film of resin to a 54-inch to 60-inch (1.4m to 1.5m) wide web of continuous fabric, he points out, “the resin must be mixed and applied very accurately.” Graco’s Larsen cites increased automation in the aircraft industry as one driver for using MMD in prepregging lines. “Suppliers are also making prepreg for wind turbines, sporting goods and automotive, and want to eliminate batch processing,” he adds. Mixing batches of resin requires using slow-reacting resins to allow for laying a film. With inline MMD, says Larsen, “prepreggers can go to faster-reacting resins.” MMD equipment reportedly also cuts waste, ensures accuracy, reduces equipment size and boosts efficiency. “Traditionally, large equipment would have been required to melt solid resins and apply them,” Larsen explains, “but now we can do it with a much smaller footprint. A draw pump with heated platens melts the material right out of the barrel, eliminating preheating and the need for a second machine and traditional two-stage process.” Kirkpatrick points out that this technology is proven. “Kirkco has supplied MMD equipment into many applications which require precision-mixed material, dispensed in thin films — for example, manufacturing of Mylar balloons, airbags and food protection wraps. All of these have used metering and mixing inline for years.”

Faster and cheaper adhesives

As manufacturers move to adhesive bonding to reduce the labor and cost of fasteners, Smith at GS Manufacturing says MMD of methyl methacrylate (MMA) adhesives is a trend. MMAs are preferred because they reduce or eliminate the need for prebond surface preparation, which saves time and labor. Smith explains, “Sanding and grinding can be eliminated because the chemistry actually etches into composites ... to provide a mechanical bond.”

To handle that aggressive chemistry, however, some MMD systems must feature stainless steel construction. Don Leone, marketing director for Ashby Cross Co. (Newburyport, Mass.), says MMA adhesives can be dispensed in all Ashby Cross equipment, but they work better in piston machines and tend to dry out in MMD systems with gear pumps. Applications can range from gluing jets into fiberglass hot tubs to attaching a 40-ft/12m boat hull to its deck. “We actually sold two machines for this to one customer,” he notes, explaining that because the material hardens quickly, it required two machines to lay a 1-inch [25-mm] bead all the way around the hull and deck perimeter in time to mate the surfaces before the adhesive began to gel.

GS Manufacturing’s Smith adds that this is why machines dispensing MMA adhesives must have a high output. “We design machines that allow an operator to lay in widths of 1.5 inches [38 mm] and higher very quickly; for example, 2 lb/min [0.9 kg/min] for Plexus [supplied by ITW Plexus, Danvers, Mass.] at a 10:1 mix ratio.”

One of the biggest MMD applications is the bonding of wind blade halves. Windsys Solutions LLC (Acworth, Ga.), a distributor for Dekumed Kunststoff- und Maschinenvertrieb GmbH & Co. KG (Bernau, Germany), has developed expertise in MMD equipment for bonding blades, delivering viscous pastes loaded with chopped glass fiber at extremely high output rates. Meanwhile, 2KM has responded to the larger blades for offshore turbines with its PolyMix 2000, a machine that is 2m/7 ft taller with a 5m/16-ft extension that can provide flow of 18 to 20 kg/min (44 lb/min) while maintaining precision in the mix ratio.

Another “big” factor is that adhesives are expensive, prompting companies to seek cost savings by buying in bulk. MMD machines offer the ability to move away from pre-mixed cartridges, accurately mixing and dispensing bulk materials. An illustrative case history is Airbus’ Stade (Germany) facility’s use of DOPAG’s VOLU-MIX equipment to apply polysulphide-based materials for sealing joints in the internal structure of the A380 composite vertical stabilizer, to prevent moisture ingress that might compromise the lightning protection system. VOLU-MIX equipment helped to achieve a 70 percent cost reduction by accommodating 30-liter/8-gal drums, which allowed Airbus to discontinue the use of expensive pre-packaged cartridges. The system’s on-demand operation also eliminated waste in mixed material. “We see this fairly often,” says GS Manufacturing’s Smith. “Our customers call us when they get to where they are using enough adhesive to make buying one of our machines cost-effective.”

“We also have machines that are used to refill the adhesive cartridges,” Smith adds, noting that even in a volume-production environment, there are applications where cartridges work better, such as in small, hard-to-access areas. Indeed, similar systems from a variety of manufacturers are used in-house by most MMA suppliers, including LORD Corporation (Cary, N.C.), SCIGRIP Smarter Adhesive Solutions (Durham, N.C.) and Henkel AG & Co. KGaA (Rocky Hill, Conn.).

Cauthen says another recent trend in adhesives application is to mix powders with liquids on demand. He details, “Normally, you would do this in a bulk mix because the chemistries are very expensive and you want the cheapest price possible. But now they want to add fillers like glass beads inline vs. batch bulk processing, so we have developed equipment to do this.”

Heating and vacuum degassing

MMD suppliers assert that the increased use of carbon fiber in closed molding has increased the use of high-performance resins. Graco’s Larsen says this means that MMD systems must also be capable of “appropriate resin conditioning, such as heat and degassing.” Windsys Solutions LLC president Dieter Wingel says that heating is a key MMD parameter because, for epoxy and polyurethane, viscosities are temperature-dependent. He also points out that, as the viscosity changes, it changes the internal pressure throughout the setup. “So you want to keep the material at a constant temperature,” he says. “This becomes especially critical if you don’t use flowmeters and rely on what you theoretically put through the pumps.”

Austad at MVP explains, “If we can control the environment and maintain temperature from the start” — in the tote or drum, for example — “then the parts are more consistent.”

Cauthen says that heated systems help to stabilize the processing environment, especially in unheated plants where cold winter temperatures can increase resin viscosity and alter its reactivity. To achieve this, Mahr offers electrically heated vessels, valves, fittings, lines and hoses.

Mandeveille says Sealant Equipment & Engineering offers thermal-electric and water-based heating technologies, both of which can heat and cool. Water heating systems, he says, show better wear resistance than electrical heating for automated systems where robotic operation causes a lot of hose movement. Cost is also a factor.

APT’s Phillips comments, “Every inch of fluid in the system has to be controlled if you are doing it right.” APT, therefore, uses independently controlled ceramic-enclosed infrared (IR) heaters for each resin component’s compartment so that a separate temperature can be maintained for each.

Leone at Ashby Cross adds that multiple, independently controlled zones allow the user to keep temperatures relatively low in the bulk tanks, and then ramp them up as the resin moves toward the mold so that only the injected resin reaches the target temperature. “If you heat a 50-gal drum to the full temperature, but only use half of that material, then you are not only wasting energy,” he says, ”but also degrading the bulk resin and hardener over time, with repeated heating to the higher temperature.”

Degassing is often necessary, especially in polymer casting and RTM, to prevent air bubbles and moisture uptake. “A resin with air in it is like a sponge for water,” says Graco’s Larsen. “If you don’t pre-degas, you will degas as the resin enters and flows through the dry laminate stack. Vacuum degassing eliminates porosity, especially with fast cycle times.” He admits that this function adds complexity to MMD equipment and isn’t always necessary: “There is a lot of infusion being done without degassing,” he allows, but insists that “where parts are thinner and more lightweight, the elimination of air voids becomes more critical, and parts manufacturers are looking to the MMD equipment to help.” Gary Bauer at 2KM North America (2KMNA, Parry Sound, Ontario, Canada) sees demand growing for degassing “as companies refine resin infusion processing and work on more of the details.”

As wind blades get larger, especially for offshore wind turbines, Bauer believes that larger equipment will be needed to handle the increased mold volumes. Wingel at Windsys Solutions LLC argues that it is not really possible to degas inline with wind blades or boat hulls and other big parts, because the very high resin throughput required by those processes does not allow the time needed to achieve full degassing. However, for applications with slower flow rates — such as medical devices and electronics — degassing is easily achieved in onboard tanks. Wingel concedes that very large tanks can offer hours of continuous flow, but warns that the rate of degassing is affected by many factors, including viscosity. “For some applications, degassing could be achieved with a flow rate of 20 liters/hr [5 gal/hr], where in others it might need to be 5 liters/hr [1 gal/hr].”

That said, 2KM worked successfully with a customer to replace a traditional “infusion vessel,” which heated and batch-degassed the resin, to inline vacuum degassing and heating at flow rates from 1 to 60 liters/min (0.3 to 16 gal/min). Its ResinMix equipment feeds resin directly from a drum to a flow-through heater to reduce viscosity, then breaks the stream into small droplets in an evacuated chamber to remove the air and, finally, supplies degassed resin to the metering system. Most companies that do infusion only degas the resin component, but some in Europe now degas the hardener as well.

No going back

MMD suppliers say the need for control can only increase in the future. “As the industry has matured, molders are beginning to realize that it takes far more precision than earlier thought to gain the needed control over quality and material cost,” says JHM Technologies’ Moore.

“Our goal has always been to emulate the ‘rhythm’ and minimal operator requirements of thermoplastic injection molding,” Moore contends. But Clas-Åke Johansson, VP marketing for Aplicator System AB (Mölnlycke, Sweden), points out that although electronics and PLC control have increased MMD efficiency, “composites production is still too slow to compete with … injection molding.” Aplicator System’s MMD offerings include Ri2 equipment for infusion and VIM5 for RTM (see photos at left), as well as IPP-8000/T200 for wind blade adhesive application and P4 systems for automated preforming.

Most suppliers, however, anticipate additional challenges and opportunities as new composite materials and end uses come into view. On the material front, Mahr’s Cauthen sees a trend toward nanoparticle and nanofiber additives. As these materials are added to production resins, molders will demand new types of MMD equipment to prevent, for example, the entanglement of nanofibers during mixing. Leone of Ashby Cross believes that, among new markets, civil engineering will be huge for composites. “Just the sheer size of the surfaces will place new demands on MMD equipment,” he contends, noting that Ashby Cross supplied such an MMD system (see photo, at left) for use in the assembly of the massive “far detector module,” a massive 15.6m tall, 15.6m wide and 60m deep (51-ft by 51-ft by 197 ft) structure in Ash River, Minn., designed to help scientists detect neutrinos in the NOvA neutrino detector project (www-nova.fnal.gov/nova_experiment_print.html).

“The trend I see is that many companies are getting very sophisticated and specific in what they need,” APT’s Phillips sums up, “and it is up to us to come as close as possible to giving them everything on their wish list.”

Related Content

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreRUAG rebrands as Beyond Gravity, boosts CFRP satellite dispenser capacity

NEW smart factory in Linköping will double production and use sensors, data analytics for real-time quality control — CW talks with Holger Wentscher, Beyond Gravity’s head of launcher programs.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreRead Next

Inline static mixers

Interfacial Surface Generator (ISG) static mixers from Charles Ross & Son Co. (Hauppauge, N.Y.) can be quickly installed in existing meter/mix/dispense (MMD) equipment piping at low cost.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More

.jpg;maxWidth=300;quality=90)