Magnetic 3D printing the next generation of tailored composites

Fortify uses magnetic fields and digital light processing to produce tailored microstructures for high-resolution, 3D printed composite parts — and enables the next generation of multiscale, multifunctional composite metamaterials.

Fortify (Boston, Ma., U.S.) was founded in 2016, based on composite 3D printing research by Josh Martin (Fortify’s CEO) and Randall Erb, director of the DAPS Lab at Northeastern University in Boston. (Erb is also a co-founder of both Boston Materials and Fortify.) Their goal was to enable fast production of composites with optimized microstructures. The patented Fluxprint technology they developed uses magnetic fields and digital light processing (DLP) — but with highly-filled resin systems — to produce custom microstructures in high-resolution, 3D printed composite parts.

Fluxprint vs. DLP

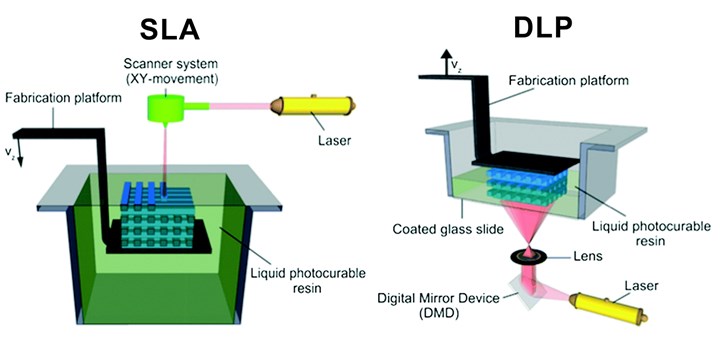

Both DLP and stereolithography (SLA) are currently seen as the 3D printing technologies offering the highest part complexity and precision. Both rely on the use of light — typically ultraviolet (UV) — to cure a photosensitive resin which usually comprises epoxy or acrylic and methacrylic monomers. The light is digitally directed to shine on the resin in the system’s tank to create the shapes or patterns for each layer. The fabrication platform is moved after each layer, enabling the next layer to printed and proceeding to a finished, solid part.

DLP projectors and SLA date back to the beginning of 3D printing in the 1980s. DLP printers tend to be larger because they house the actual light projector. Most SLA and DLP machines use thermoset polymers, but EnvisionTEC makes a printer that can also use thermoplastics. Both have traditionally used neat polymers without reinforcement.

“DLP platforms are capable of sufficient production rates and quality,” says Fortify CEO Josh Martin, “but the mechanical properties have always been a challenge. Our core thesis is that a step change in performance won’t be accomplished by polymer chemistry alone. However, exploiting the unique properties of composites in the high-resolution additive industry will be a game changer.”

He explains that Fortify specializes in UV-cure of highly-filled technical resins using unique additives and controlling the orientation of these property-enhancing additives in the print. Fillers include glass, carbon and ceramic fibers as well as particules. Technical resins include acrylate and methacrylate-based (PMMA) or epoxy-based, cationic-based – which Martin explains are more conventional to the coatings industry. Top resin manufacturers around the world (BASF, DSM, Dupont, and others) are investing heavily to advance the properties of their additive materials. Fortify is able to select the best of these advances to add their reinforcing technology.

Control of fiber orientation is achieved by using a magnetic field. As Fortify 3D prints a part using its Fluxprint technology, fibers are magnetically aligned voxel-by-voxel to meet the part’s load requirements. (See the process in action in the video above.) For non-magnetic reinforcing materials, such as ceramic and glass particles and fibers, proprietary magnetic-labeling techniques are used to coat the fillers in a way that makes them magnetically responsive and compatible with the resin.

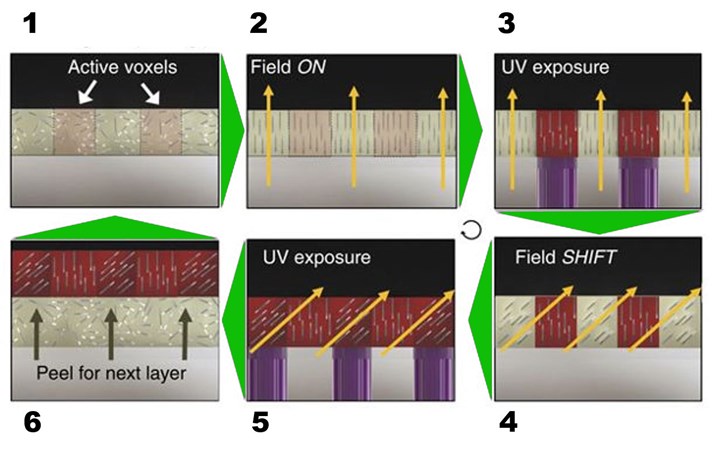

The Fluxprint process is shown in the image above and described as follows:

- A layer of feed material is supplied to the build area with reinforcement randomly aligned.

- Magnetic field is applied to align the reinforcement.

- Active voxels are exposed to UV light, fixing the reinforcement orientation in those voxels (now shown in red).

- The magnetic field is shifted to set new orientation of reinforcement.

- Repeat UV exposure step to fix orientation for the next set of voxels (repeat as needed).

- Build plate adjusts to bring in uncured feed material matrix for next print layer.

The Fluxprint technology enables voxel level control over fiber orientation during the printing process. Source | “Designing bioinspired composite reinforcement architectures via 3D magnetic printing” by Joshua J. Martin, Brad E. Fiore and Randall M. Erb, Nature Communications volume6, Article number: 8641 (2015).

Why voxel-by-voxel?

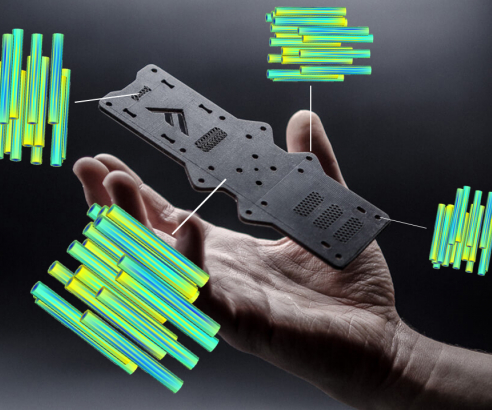

“Every geometry has unique strain and stress states,” Martin explains. “Most composites are hand manufactured to account for this. We’re digitizing the process. For example, if you can properly reinforce a UAV frame, you can use less material. Any application that works against gravity will fundamentally benefit from this.”

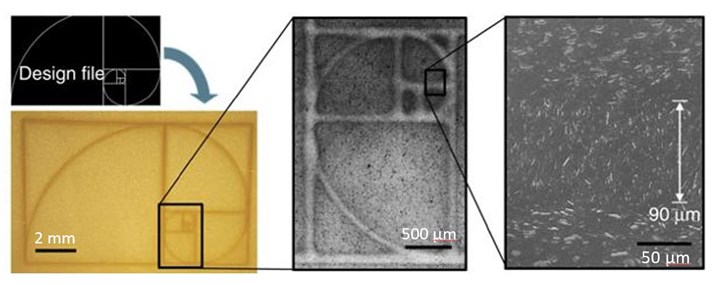

Voxel-by-voxel printing is also inherently high resolution. “This is the highest-resolution composite manufacturing process to date,” says Martin, noting that fused deposition modeling (FDM) — where unreinforced or milled fiber-reinforced plastic filament is melted and deposited onto a print bed — has a resolution in the hundreds of micrometers while Fluxprint’s is within tens of micrometers. “So, that’s an order of magnitude improvement, which enters the territory beyond what is perceived by the naked eye. This kind of resolution is very important to a wide variety of end-use parts.”

Fortify’s Fluxprint magnetic 3D printing technology can orient fibers to reinforce “peg” projections on injection molding tools. Source | Fortify.

“We offer injection molding tools that are significantly cheaper than traditionally machined metal, can be delivered in a fraction of the time and provide features that conventional machining practices would not be able to achieve,” Martin continues. “One customer would iterate through 12 different designs per year machined from aluminum. We’ve compressed their time to market significantly, producing more than a dozen designs in several months. They can now move from design to parts on the shelf in a matter of weeks.” Another benefit is the ability to reinforce projections, referred to as ‘pegs’. These high-aspect ratio extrusions often pull out. Reinforcement prevents that, while holding tight tolerances.

Read more about Fortify’s benefits in injection molding tooling in CW’s sister magazine Additive Manufacturing.

Open materials, new developments

Fortify pursues an open materials approach. “We don’t want to limit our customers’ ability for growth and exploration within additive,” explains Fortify VP of applications Karlo Delos Reyes. “We guarantee our customers flexibility and the best available materials by embracing open innovation.”

“We partner with large manufacturers of polymers and tailor the surface chemistry of additives,” says Martin. He notes that each filler has its own pros & cons regarding wear resistance, performance at temperature, etc. “For fibers, length ranges from a few µm to a few mm, depending on the application. Where we need surface resolution, we use a higher percentage of smaller-length additives. Where we can afford a rougher surface, but want to optimize for tensile strength, for example, we use longer fiber additives.”

One of Fortify’s strategies is to partner with industry leaders and suppliers to leverage expertise and enable cross-pollination of ideas. Fortify recently announced a partnership with DSM Additive Manufacturing (Hoek van Holland, Netherlands and Elgin, Ill., U.S.) to develop high-performance composite materials that will be used in Fortify’s printing systems to achieve expanded mechanical and temperature performance. “They will expand our resin palette,” says Martin, “and we’re excited to work with them to develop cutting-edge resins.”

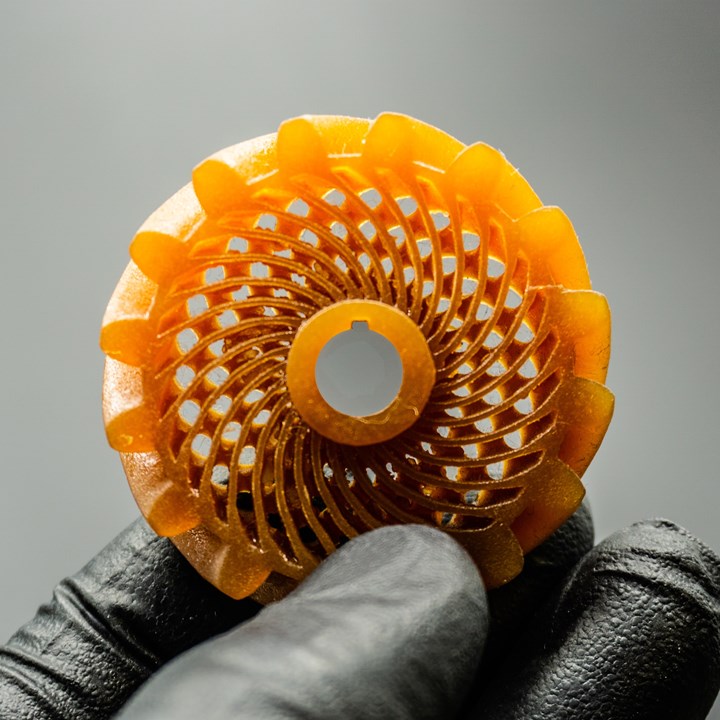

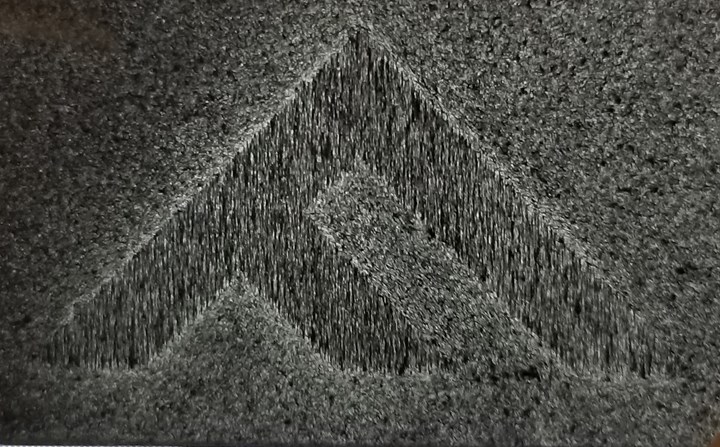

Glass fiber-reinforced composite part made with Fluxprint. SOURCE | Fortify.

Z-direction reinforcement and applications

Fluxprint is still printing by layers. So, is it possible to achieve z-direction reinforcement? “If you are printing 2-millimeter long fibers, you can’t put those in the z-direction,” says Martin. “But you could get shorter fibers into z-orientation. We’re looking at multiple length scales and we see that developing in the future for optimized load transfer.”

Fortify is already producing parts for UAVs, including propellers, and sees many more such applications in aerospace. “We have a small build area, so we are focusing on applications where we can easily meet smaller part volumes,” says Martin. “This is a mature ecosystem, but we offer a new level of performance in mechanical properties at high temperatures and tolerances.” He cites being able to improve a part’s heat deflection temperature and explains there are dozens of under-the-hood parts in automotive that need to provide strength and stiffness while exposed to 160°C temperatures. “Such parts with complex geometries lend themselves well to 3D printing with our technology. Compared to the current method of molding and machining parts out of PEI (polyetherimide), we offer higher performance, a shorter lead time and a high potential for lower cost.”

Tooling is also a current market, including dies, jigs and fixtures for injection molding. “Again, our parts are stiffer, stronger and have higher temperature resistance, maintaining dimensional accuracy in service,” says Martin. “But their real value lies in not requiring significant post-processing, such as what is needed when using EDM machines, and yet they match the quality of fixtures made with these traditional methods, including CNC-milling.”

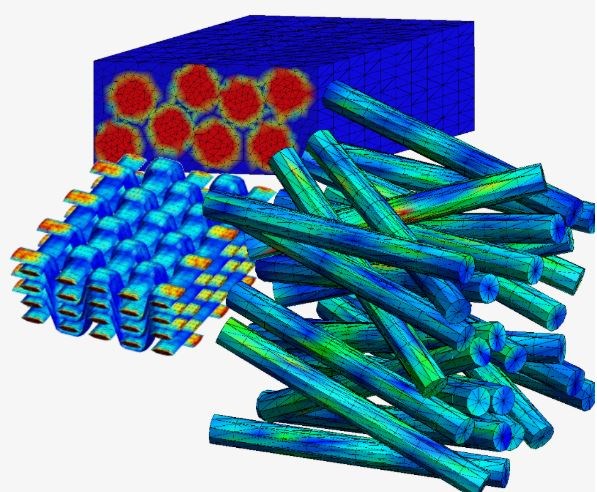

Source | MultiMechanics

Advancing the next generation of multiscale, multifunctional composites

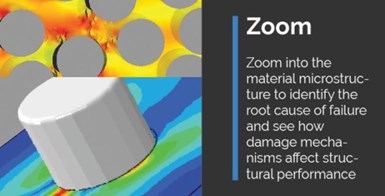

Fortify has partnered with MultiMechanics (Omaha, Neb., U.S.), a developer of multiscale modeling and simulation software for advanced materials. This partnership is interesting for a number of reasons. First, Fortify will use MultiMechanics’ flagship product, MultiMech, to predict the performance of parts and optimize their design and fiber orientation before they are printed. Thus, MultiMech will act to provide the feedback for closed-loop iterative design, enabling users to more quickly tailor and optimize Fluxprinted composite parts. Fortify and MultiMechanics also plan to integrate MultiMech into Fortify’s INFORM generative design and print control software. Thus, from design to virtual testing to printing — all functions will be controlled within a single, digital stream.

For the second point, it’s important to understand what MultiMechanics is offering through its MultiMech software:

- Multiscale finite element analysis, including modeling of a practically unlimited number of scales (e.g., nano, micro, ply, laminate, part).

- Automatic generation of complex, 3D finite element microstructures, and modelling of almost any material microstructure, including continuous and chopped fiber, particles, voids, foams, fabrics, etc.

- Model effects of microscale constituents, including interactions, volume fractions, distribution and orientation, plus import process-induced variation from programs (e.g. Moldex3D, Moldflow).

- Analyze how manufacturing variation affects part performance and perform damage modeling including multiscale transition of micro-cracks into macro-cracks.

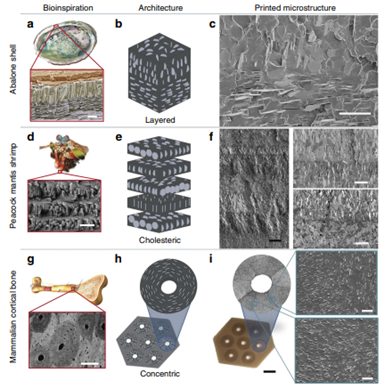

This goes back to why Martin and Erb started Fortify in the first place. In their 2015 article, “Designing bioinspired composite reinforcement architectures via 3D magnetic printing” they state:

“… we demonstrate that we can now design and evolve elaborate reinforcement architectures that are not found in nature, demonstrating a high level of possible customization in discontinuous fiber composites with arbitrary geometries.”

Martin and Erb discuss natural composites which utilize discontinuous fibers and reinforcing particles organized into multiscale, complex architectures to achieve superior properties versus their constituents. An example given by Qunfeng Cheng in a 2017 Materials Today article is nacre in abalone shells. Comprising 95 vol% inorganic aragonite and 5 vol% organic protein matrix, nacre’s fracture toughness is 3,000 times higher than that of aragonite. Cheng notes this shows an ‘amplification effect’ in mechanical properties which goes far beyond the rule of mixtures in traditional composites.

In the 2018 Advanced Materials article, “Additive Manufacturing as a Method to Design and Optimize Bioinspired Structures”, the authors Audrey Velasco-Hogan, Jun Xu and Marc A. Meyers assert that the hierarchical structure of materials like nacre, bone, bamboo and crustacean shells are what enables their impressive combination of strength, modulus, lightweight, toughness and fatigue resistance. Their constituent particles/filaments and matrix are organized differently at each level (e.g., nano-, micro-, meso-, macro-), varying the properties at each level (i.e., a multiscale composite). When combined with efficient interfaces between the levels, this hierarchical structure works synergistically to mitigate crack propagation and enhance toughness while maintaining hardness — something that has not yet been achieved in ceramics after roughly a century of trying.

“… this hierarchical structure works synergistically to mitigate crack propagation and enhance toughness while maintaining hardness — something that has not yet been achieved in ceramics after roughly a century of trying.”

Future of composites and INFORM

This is the future of composites: designing hierarchical composites with unique properties tailored for precise applications. And it is already being advanced, rapidly. For example, the German Aerospace Center (DLR) Institute of Structures and Design in Stuttgart has also partnered with MultiMechanics to understand how temperature change affects the microstructure and material behavior of ceramic matrix composites (CMCs). This analysis is deemed crucial for DLR’s future CMC components production, including nozzles for rockets and thermal protection systems for re-entry vehicles among others. “Our work at MultiMechanics for the last ten years has been dedicated to accurately connecting microstructural behavior of advanced materials to the overall part performance and its manufacturing,” says Dr. Flavio Souza, president and CTO of MultiMechanics. “MultiMech allows us to model microstructural cracks and determine how they would affect the overall composite part,” states Neraj Jain, group leader in the Department of Ceramic Composites and Structures at DLR. “MultiMech’s efficient integration with our other FEA tools like Abaqus and ANSYS increases our productivity and brings us closer to our aim to optimize CMC materials virtually.”

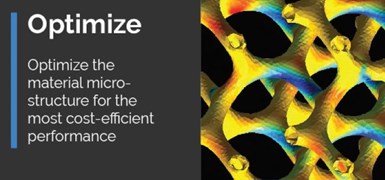

Once these composites have been optimized virtually, they are then printed, with MultiMech embedded into Fortify’s INFORM software, which is already geared toward organic, load-optimized architectures via its generative design backbone. (Note that Solvay’s Composite Materials business unit has also invested in both MultiMechanics and 3D printing technology.)

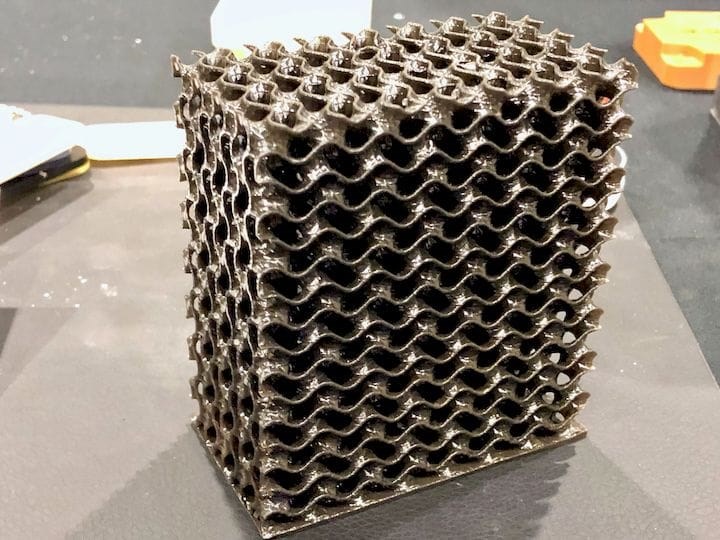

Fiber-reinforced lattice, design provided by nTopology. Source | Fortify.

“INFORM uses advanced algorithms to optimize fiber orientation for each part,” explains Martin. “Where traditionally, the 3D printing workflow starts with STL to slice the design, ours starts with FEA (a model with stress and strain) and then decides what voxels to separate that modeled design into and how to orient the fibers. We progress through iterations, aligning the fibers with stress/strain field vectors, and then simulate how that print will behave and use that data to refine and optimize the design, achieving microstructural generative design.”

Only the beginning

Note that these future composites include a range of materials. The Naval Research Laboratory (NRL, Arlington, Va., U.S.) is developing CMCs using a ceramic matrix with a secondary ceramic reinforcement via nanoparticles and/or filaments. These CMCs may also use continuous fiber reinforcement. In other words, different constituents and architectures may be used at each level for the enhanced toughness and tailored electrical and thermal properties required (for example, in hypersonics, read more in my July 2019 feature on nanocomposites).

SOURCE | Figure 3, “Designing bioinspired composite reinforcement architectures via 3D magnetic printing” by Joshua J. Martin, Brad E. Fiore and Randall M. Erb, Nature Communications, volume 6 (2015).

Hierarchical composites are also being printed and tested using reinforced epoxy inks and thermoplastic polymer matrices. This is perhaps the biggest upside for Fortify as a startup. It is not just preparing for the composites of the future, it is already designing and producing them. And even though what it has already achieved is impressive — it’s only the beginning.

Related Content

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreOne-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read More

.jpg;maxWidth=300;quality=90)