Looking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

- Materials

- Hi-Temp Resins

- Aerospace

- Processes

- Resins

- Prepregs

- Automotive

- Injection/Overmolding

- Consumer

- RTM

- Reinforcements

- Filament Winding

- Mass Transit

- Design & Tooling

- Markets

- Wind/Energy

- Machining/Drilling

- Cutting/Kitting

- Fabrics/Preforms

- Compression Molding

- Editorial

- Pultrusion

- Core

- Construction

- Infusion

- Glass Fibers

- Curing

- Marine

- Thermoplastics

- Defense

- Nanomaterials

- Carbon Fibers

- Epoxies

- ATL/AFP

- Materials Testing

- Design/Simulation

- Natural Fibers

- Molds/Tools

I am reading a book called The Aviators, by Winston Groom. Engagingly written, well researched and insightful, it tells the story of the three aviators who, Groom argues, are most responsible for the survival and development of the US aviation industry, especially in its nascent period in the early 20th Century: Eddie Rickenbacker, Jimmy Doolittle and Charles Lindbergh.

One of the things I find so intriguing about the study of such a history is the opportunity to understand people and events in the context of their time. Too often, when we study historical events, we are (whether we know it or not) biased by the outcome. We know, for instance, who won the war, but we don’t appreciate that those fighting in the war didn’t have that certainty of outcome; in fact, they labored under great uncertainty, fear and distress. (This is why historians so highly value diaries and journals — they are untainted by hindsight.)

Today, when we look at the aerospace industry, we see the result of 100-plus years of innovation, daring and technological advancement that have led, apparently, to this point: Global, trans-ocean, high-speed passenger travel; supersonic, super-weaponized fighters; stealthy, nimble unmanned aircraft; manned and unmanned spacecraft.

There was, however, a time when such an outcome was inconceivable and, thus, unlikely. Groom makes clear in The Aviators that governments and private industry struggled, early on, to understand if and how the airplane could be useful as a vehicle for commercial or military use. The United States military, in particular, was reluctant to incorporate aircraft into its arsenal, even after the success fighter pilots enjoyed in World War I.

This uncertainty is one reason why Lindbergh’s nonstop, transatlantic flight from New York to Paris in 1927 was so monumental. When Lindbergh landed in Paris, he almost single-handedly ushered in a new mode of human travel. Indeed, today it’s extremely difficult for us to imagine what our lives would be like without the speed and convenience of air travel. It seems like it was inevitable. But before Lindbergh took off, very few people thought it could be done. No less than Wilbur Wright, one of the inventors of the first airplane, in fact, believed that such a flight in an airplane was impossible. Lindbergh succeeded because he was willing to apply technology and ideas that others hadn’t: He flew a more aerodynamic mono-wing plane; he flew alone (no navigator); he eschewed extra weight (he even trimmed the edges off of his navigation maps!); he flew what was, effectively, a fuel tank with wings.

Of course, the aerospace industry is not unique. Every paradigm-shifting invention throughout human history has been met with skepticism. Even the wheel itself, one can imagine, must have induced much head-scratching before its potential was realized.

Composites are no different, and it would be helpful if we could zip 50 years into the future to get a glimpse of where carbon fiber and glass fiber structures are headed. Instead, we’re here, in the moment. In context. And what is that context? Over the past 40 years, composites have seen tremendous growth and evolution, but in some quarters, they’re still that poorly understood “niche” material — the square peg manufacturers want to squeeze into the round hole now occupied by metals and concrete and other established materials.

The times require Rickenbackers, Doolittles, Lindberghs — people willing to evangelize, innovate, take risks and apply composites in “impossible” ways. The good news is that the composites industry already has such leaders. We just need to let them fly.

Related Content

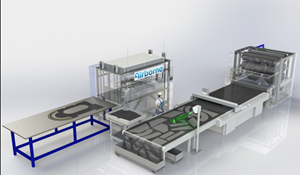

Ply stacking, cutting process optimized via automation, smaller footprint

CAMX 2024: Schmidt & Heinzmann customers are able to produce SMC or dry fiber fabric stacks more efficiently thanks to the AutoCut Pick&Place system.

Read MoreAitiip concludes HELACS project with waterjet cutting demonstration

Novel platform involving digital twin and human-robot collaboration succeeded in cutting a component from the 19th section of an A350 wing, highlighting its ability to enable composite structure recycling.

Read MoreDigital cutting, kitting streamlines advanced materials handling

CAMX 2025: Zünd is showing how it combines intelligent cutting systems and software to boost productive composites environments, as well as recent technology synergies with Loop Technology.

Read MoreAirborne to supply composites cutting/kitting equipment to Airbus Helicopters

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More