Fiber Types

Glass, carbon or aramid fibers are the most common choices for composite parts. The best fiber for a particular application depends on the required strength, stiffness, corrosion resistance and budget. Glass is the most commonly used and least expensive fiber, with E-glass currently costing about $0.50/

Glass, carbon or aramid fibers are the most common choices for composite parts. The best fiber for a particular application depends on the required strength, stiffness, corrosion resistance and budget.

Glass is the most commonly used and least expensive fiber, with E-glass currently costing about $0.50/lb to $5/lb. Silica makes up at least 50 percent of glass fiber, with a variety of metal oxides and other ingredients added to customize the fiber characteristics. E-glass (or electrical glass) has aluminum, boron, calcium and other compounds in its makeup, creating an excellent electrical insulator. S-glass (or high-strength glass) while more expensive than E-glass, is 40 to 70 percent stronger and more corrosion-resistant because of the addition of more silica oxide as well as magnesium and aluminum oxides. Even greater corrosion resistance is offered by E-CR (or corrosion- resistant) glass fibers.

Carbon fiber is more costly than glass, with prices ranging from around $7/lb for 48K or heavy tow to around $15/lb for 12K or aerospace-grade tow, and into the $100/lb range for very high-performance grades. (These price estimates are for general comparative purposes only and may vary greatly depending upon supplier, volume usage, and demand from other markets.) Briefly, carbon fiber (consisting of 80 to 95 percent carbon) is made by heating polyacrylonitrile (PAN), pitch, rayon or other organic precursors to very high temperature, usually around 1800°F/ 982°C, under tension in an inert atmosphere. Carbon fiber is available in “tow” form, essentially a bundle of untwisted carbon filaments. 12K tow has 12,000 filaments and is commonly sold according to “modulus” category: standard or low (33-35 Msi), intermediate (40-50 Msi), high (50-70 Msi) and ultrahigh (70-140 Msi). Modulus, sometimes referred to as modulus of elasticity or Young’s modulus, is a mathematical value that describes the degree of stiffness of a material by measuring its deflection or change in length under loading or stress. While carbon fiber is much stiffer, it is also more brittle than glass or aramid, and when attached to a metal, a barrier material, such as a ply of glass fiber, must be used to avoid galvanic corrosion.

Heavy carbon tow — a single tow with high filament counts, from 48K up to 320K — can be made more economically using textile-grade precursor and offers basic mechanical properties of approximately 33 Msi/228 GPa modulus and 525 ksi/3.62GPa tensile strength — comparable to low- or intermediate-grade aerospace grade fiber. Besides costing less, heavy tow enables faster placement of material in fabrication operations, like pipe winding.

According to Zsolt Rumy, president of Zoltek Inc. (St. Louis, Mo., U.S.A.), a heavy tow carbon fiber supplier, while aerospace grade fibers are made with a more refined precursor material and require more documentation and control of the process, ultimately heavy tow or commercial fiber will offer offshore product producers a more stable pricing structure.

“Our goal is to make commercial fiber a commodity product based on sustainable prices that will not fluctuate with high-tech aerospace demands,” states Rumy.

Aramid fiber, specified for its excellent impact resistance, costs between $12/lb to $30/lb. Aramid is an aromatic polyamide that provides exceptional flexibility and impact resistance, used primarily for ballistic protection or containment and impact protection. While less stiff than carbon, aramid is stiffer and much lighter than glass.

Read Next

Composite Components: The String And The Glue

Fibers — whether glass, carbon or more esoteric varieties like aramid — are the backbone of composites. A single glass filament, thinner than a human hair, has a tensile strength of approximately 500 ksi/3.5 GPa, but essentially no compressive strength. To achieve a structural building material, fibers are enc

Read MoreManufacturing Methods

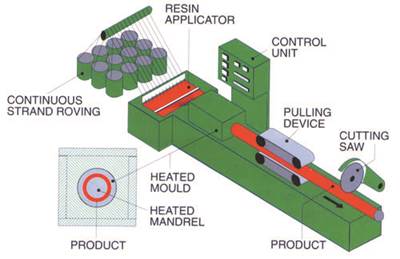

Composite parts can be made in a controlled factory environment and delivered to the site as finished pipe, beams or grating, or fiber and resin can be combined on site to make or repair structures. Regardless of the fabrication method and its location, a quality composite requires that the reinforcement be co

Read More