Download today's news from CAMX 2019: Tuesday, Sept. 24

CW is reporting live from CAMX 2019 this week in Anaheim, California. Read today’s show headlines about the keynote speaker from Protolabs and award nominees.

This week, CW is reporting live from the show floor at CAMX 2019, held at the Anaheim Convention Center in Anaheim, Calif., U.S., today through Thursday.

Each day of the show, we produce a daily newspaper, the Show Daily, with the latest news, events, and exhibit information from the show. Not at the show? No problem. We’ll also post links to the Show Daily here.

Read today’s CAMX headlines: Show Daily: Tuesday, Sept. 24

Below are a few of the top stories from today’s issue:

CAMX 2019 keynote speaker Vicki Holt, CEO of Protolabs

Keynoter to kick off CAMX 2019

CAMX 2019 starts officially today with the General Session, 8:30-10:00 in the Ballroom, on Level 3 of the Anaheim Convention Center. This year’s keynote speaker is Vicki Holt, CEO of Protolabs (Maple Plain, Minn., U.S.). Protolabs is a manufacturer of custom prototypes and on-demand production parts, with manufacturing facilities in five countries. The company offers additive manufacturing, CNC machining, injection molding and sheet metal fabrication services and specializes in quickly converting digitized designs into real-world parts. Holt will share with the CAMX audience why the way manufacturing is done needs to be rethought and approached differently to meet the needs of the future.

CAMX, ACE award nominees span materials, processes

There are two parts competitions at CAMX, the CAMX Awards and ACMA’s Awards in Composites Excellence (ACE). You can find nominees for both awards at the back of the CAMX exhibit hall. Winners of the CAMX Awards will be announced this morning at the General Session that officially opens the show (8:30 a.m., main ballroom). ACE winners will be announced today at 2:00 p.m. in the ACE exhibition area.

Nominees for the CAMX Combined Strength Award are:

- Institut für Textiltechnik of RWTH Aachen University: Highly Precise Laser Drilling of Carbon Fiber Preforms for Fastener Integration

- Mahindra & Mahindra: Lightweight Energy Absorption System for Vehicle Front End

- MultiMechanics and Fortify: Partnership to Improve Predictability of 3D Printing

- General Atomics: Novel Thermoplastic Joining Technique

Nominees for the CAMX Unsurpassed Innovation Award are:

- BGF Industries: Thermoplastic 5G Radome

- Boston Materials: Novel Z-Axis Milled Carbon Fiber Reinforcement Using Sustainable Materials

- Chem-Trend: Zyvax 1070W Non-Silicone Water-Based Release for Aerospace Industry

- Engel: Processing Technology for Maximum Performance with Carbon-Based SMC Grades

- Fortify: Using Magnets to 3D Print Composites with Optimally Aligned Fibers

- General Motors: CarbonPro Pickup Box

- General Photonics: Optical Transmission Scanner for Quantitative Characterization of Advanced Materials and Composites

- Inflatable Composites: Inflatable Composites Air Core Composite Technology and Materials

- International Islamic University Malaysia: Sustainable Lightweight Composite Materials

- Magna Exteriors: Composite Space Frame

- Spirit AeroSystems: Advanced Structures Technologies and Revolutionary Architecture (ASTRA)

- Sunrez: Composite 463L Cargo Pallet

- TPAC/Saxion UAS: Rotorcraft Access Panel From Recycled Carbon PPS

Nominees for the ACE Most Creative Application Award are:

- Appalachian Plastics: Composite Light Pole

- Oak Ridge National Laboratories: First 3D Printed, All-Polymeric Lightning Strike Protection System for CFRPs

- University of Tennessee: Carbon Fiber Braided Arched Beams in Park & Recreation

Nominees for the ACE Equipment and Tooling Innovation Award are:

- e-Xstream engineering: State of the Art Integrated ICME and Data Management Solution

- Fives Lund: In-Process Inspection for Composites Manufacturing

- Fortify: 3D Printing Magnetically Aligned Composites

- HP Composites: Air Press Molding

- InSitu Composites: In-Situ Impregnation of Fiber Tow for Thermoplastic Composite AM/AFP

- JETCAM International: CrossTrack MTL

- Mikrosam: Multi-Robot System for Automated Tool-less Layup of Thermoplastic UD Tapes

- Mouldbox: Automating the Design and Manufacture of Composite Tooling Using AI

- MultiMechanics: Virtual DMA to Characterize the Viscoelastic Behavior of Complex Microstructures

- University of Tennessee: AR/VR Modules for Composites Manufacturing STEM, Work Force and Training

Nominees for the ACE Material and Process Innvovation Award are:

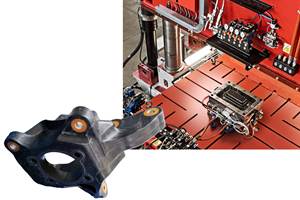

- Engel: Processing Technology for Maximum Performance with Carbon-Based SMC Grades

- Magna Exteriors: In-Mold Assembly Rotational Kinematic Linkage

- Spirit AeroSystems: Advanced Structures Technologies and Revolutionary Architecture (ASTRA)

- Toray Performance Materials: Envir-Bond

- Vistex Composites: Automated Manufacturing of Composites Using Smart Compression Molding Process

Nominees for the ACE Infinite Possibilities for Market Growth Award are:

- Continuous Composites: The Future of Manufacturing

- Hydronalix: Unmanned Composite Rescue Buoy for Emergency Lifesaving Operations

- University of Delaware: Tailorable Universal Feedstock for Forming (TuFF)

Nominee for the ACE Innovation in Green Composites Design Award is:

- LyondellBasell: Styrene-Free SMC That Meets California Proposition 65

Related Content

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreMaterials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreDucati introduces lightweight motorcycle seat support rear frame

Forged molding compound (FMC) material from Mitsubishi Chemical and Gemini Composites replaces aluminum part on Ducati Hypermotard 939, reduces part weight by 40%.

Read MoreA digital twin to validate SMC performance in suspension structures

High-fidelity, anisotropic behavior material card, integrated with process simulation, structural FEA and validated with CT and physical tests enables optimization proven in award-winning SMC suspension knuckle.

Read MoreRead Next

From the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)