Injection/Overmolding

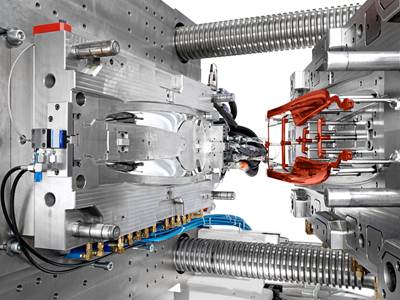

Fiber Dynamics invests in GX 1100 DCIM from KraussMaffei

Direct compounding injection molding (DCIM) enables the composites company to develop, test and protect its own recipe formulations, while increasing cycle times by eight times and reducing energy consumption.

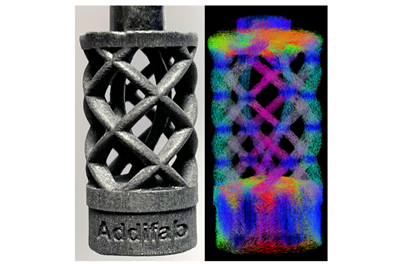

Read MoreXnovo Technology, Exciscope introduce X-ray tensor tomography technique

Through a strategic partnership, the companies introduce the FiberScanner3D module, dedicated to bringing more rapid, reliable and robust fiber structure characterization methods to lab settings.

Read MoreKraussMaffei and partners develop sustainable, safe and stylish children’s bike

The Lion Bike is a German-made, injection molded bicycle with 40% recycled carbon fibers with zero scrap and enabling 67% lower CO2 emissions during production.

Read MoreMachinery, systems manufacturer highlights 3D printing, thermoplastics processing

CAMX 2023: KraussMaffei is featuring a variety of technologies, including Fiberform, ColorForm, RTM, extruder-based 3D printing and more.

Read MoreINN-PAEK project succeeds in 100% recyclable turbine

European project replaces complex-shaped metal structure in aircraft cooling system with injection molded thermoplastic composite material for improved sustainability.

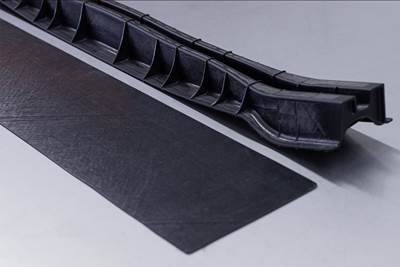

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

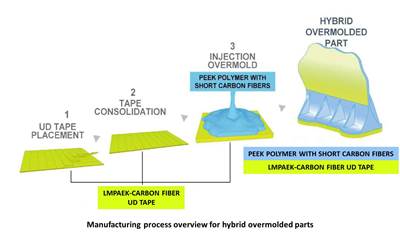

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreWindform XT 2.0 IMG brings sustainability to injection molding

Carbon fiber-reinforced PA12 thermoplastic launched by CRP Technology is a 100% recycled high-performance material derived from the Top-Line range for 3D printing.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreBlueHalo launches next generation of Intense Eye UAS

Unmanned aerial system (UAS) from BlueHalo featuring an HX5 injection-molded chassis from Alpine Advanced Materials is said to be lighter, stronger and more efficient than aerospace-grade aluminum.

Read More