ATL/AFP

CAMX 2021 exhibit preview: Gascogne Flexible

Gascogne Flexible showcases a tight release valve for ATL applications, a low coefficient of friction, solvent-free release liner and a high-porosity kraft paper for thin ply prepreg applications.

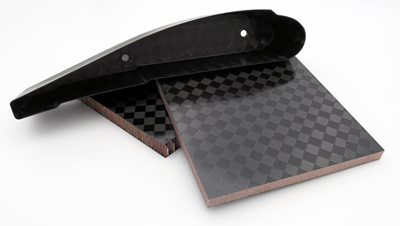

Read MoreCAMX 2021 exhibit preview: Helicoid

Designed for toughness and impact resistance, Helicoid Industries’ biomimetic fiber distribution technology, Helicoid, enhances performance of composite parts.

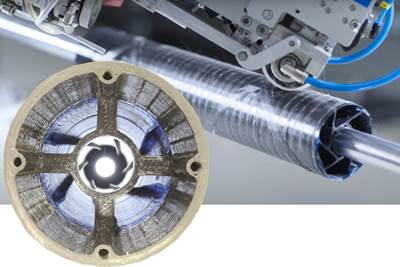

Read MoreCAMX 2021 exhibit preview: Carbon Axis

Carbon Axis showcases compact AFP solutions for the preforming of small parts with the XCell, XPlace mk2 and IdeaLab.

Read MoreThe evolution of additive composites

Defining additive composites manufacturing and how its merge with conventional processes is providing new solutions and a path forward.

Read MoreToray Composite Materials America launches flexible, adaptive 2700 prepreg system

Particularly geared toward emerging aerospace programs, the epoxy-based meets demands for high performance and process flexibility from prototype to high-volume production.

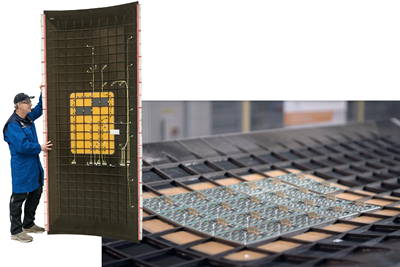

Read MoreIntegrating antennas into composite aerostructures

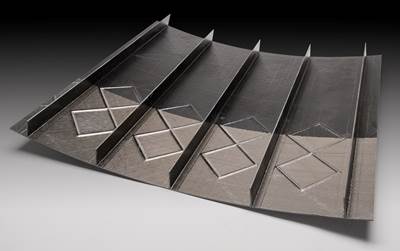

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

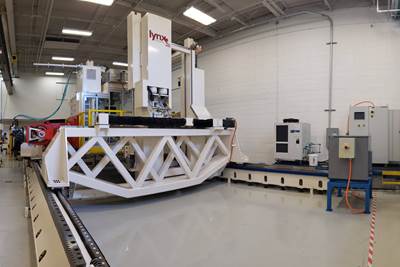

WatchUT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

Read MoreSTUNNING project successfully develops 8.5-meter thermoplastic fuselage skin

Clean Sky 2 project under the MFFD program produces two segments of an 8.5-meter-long, 4-meter-diameter thermoplastic fuselage skin via NLR’s in-house AFP machine, with consolidation plans this summer.

WatchMcNAIR Aerospace Center installs Heraeus Noblelight humm3 technology

Composites heating technology will comprise of a fully integrated system with a plug-and-play head module to further extend AFP and cylinder production capabilities.

Read MoreRocket engine thrust frame proves a strong candidate for composites conversion

The engine thrust frame of a space launch vehicle, located at the bottom of a rocket stage, joining fuel tanks to engines, must deliver strength and stiffness across a range of temperatures — cost-effectively.

Read More

.jpg;maxWidth=300;quality=90)