Pultrusion

User-friendly resins expanding composites' reach

Novel niche formulas enable composites breakthroughs for new market applications, traditional material replacement.

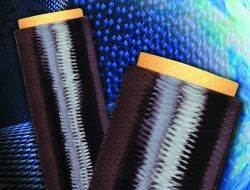

Read MoreAdvances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

Read MoreAre Hybrid Designs the Future for Composite Bridge Decks?

Teaming composites with traditional materials may be the future direction for cost-effective infrastructure replacement.

Read MorePultruded composite sheet piling replace degraded wood pilings

Creative Pultrusions Inc. has developed a tough composite sheet piling system that is lighter in weight and more corrosion resistant and environmentally stable than wood, concrete or steel piling material.

Read MoreHow Are Composite Bridges Performing?

Ongoing monitoring and inspection demonstrates that composite bridge decks meet or exceed expectations.

Read MoreAdvanced Pultrusion Takes Off In Commercial Aircraft Structures

Innovative prepreg pultrusion process forms profiles equal to autoclaved components at lower cost.

Read MoreVinyl Esters Make Tough Parts For Highly Corrosive Applications

An array of case studies showcases the growing acceptance of fiberglass/vinyl ester composites in harsh industrial environments.

Read MoreOffshore Applications: The Future Is Now

The number of composites installations continues to grow on new and existing offshore facilities.

Read MoreNew Lightweight Trailer Delivers Heavy-duty Performance

All-composite chassis and trailer design offers truckers increased cargo capacity plus greater durability.

Read MoreComposite Tether Goes To Sea

Conoco and KOP have manufactured a prototype of a carbon fiber composite tether that could extend TLP production to depths exceeding 10,000 ft/3,000 m. The design has undergone extensive static testing and fatigue loading and has been verified through hydrodynamic model testing. Sea testing is being planned.

Read More