Search Results

Showing 11 – 20 of 85 results

Advantages of building aircraft structures with composites, compared to metal, include light weight, high specific strength, superior fatigue properties, damage tolerance and the absence of corrosion. In the 1950s, Boeing began using fiberglass in its 707 passenger jets, and at the time the material made up about 2% of the overall aircraft by weight. Since then, Boeing, Airbus and other aircraft manufacturers have continued to increase this percentage with successive aircraft models. Today’s twin-aisle commercial aircraft such as the Boeing 787, first launched in 2009, and the Airbus A350 comprise approximately 50% composites by weight, largely carbon fiber-reinforced polymer (CFRP).

Demonstrator will test 30%-scale version of 52-meter composite wing with electrically-powered actuating hinged wing tip for improved efficiency and decarbonization in flight.

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Albany has signed a two-year agreement with Airbus to apply its 3D reinforced composites technology to next-generation wing substructure applications.

RTM’d five-meter-long, complex multicell flap prototype constructed via a highly integral, cost-effective manufacturing process.

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Announced at the Paris Air Show, the company’s composite demonstrator wing components are part of the wing spar.

The 4-meter mid-scale tool enables large-scale use of resin transfer molding to manufacture a composite wing spar with reduced costs and weight.

Spirit emphasizes use of modeling and simulation software for composite resin infusion technology.

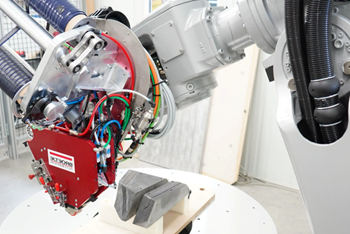

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Aviation Week discusses all-composite plane at Boeing, new composite wing at Airbus and trends driven by sustainability — composites are a key enabler for future aviation.