Search Results

Showing 1 – 10 of 19 results

Advantages of building aircraft structures with composites, compared to metal, include light weight, high specific strength, superior fatigue properties, damage tolerance and the absence of corrosion. In the 1950s, Boeing began using fiberglass in its 707 passenger jets, and at the time the material made up about 2% of the overall aircraft by weight. Since then, Boeing, Airbus and other aircraft manufacturers have continued to increase this percentage with successive aircraft models. Today’s twin-aisle commercial aircraft such as the Boeing 787, first launched in 2009, and the Airbus A350 comprise approximately 50% composites by weight, largely carbon fiber-reinforced polymer (CFRP).

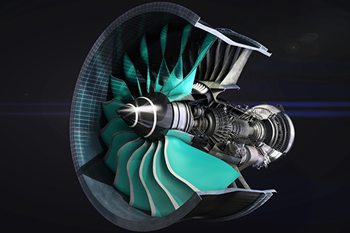

Rolls-Royce full power engine test with sustainable fuel set to deliver efficiency improvements in aviation for future narrowbody and widebody aircraft.

First tests with sustainable aviation fuel (SAF) were performed at a large, indoor aeroengine testing facility in Derby, U.K., advancing the UltraFan’s decade-long development.

The UltraFan aeroengine, with a fan diameter of 140 inches, is designed with a suite of technologies to contribute to fuel efficiency for narrowbody and widebody aircraft.

To be completed by the end of 2021, the UltraFan prototype includes the world’s largest fan rotor blades, which are made from composites.

The project aims to provide nacelle components for the engine UltraFan demonstrator. Nikkiso’s role is to reduce manufacturing costs by a new out-of-autoclave curing method.

Prepreg developed specifically for aircraft applications using high-performance and rapid-curing epoxy resin, with low-temp molding and automated processing capabilities.

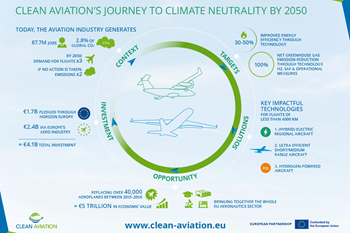

Latest progress, participants and synergies for the MFFD, UltraFan engine, RACER helicopter, Next-Gen Civil Tilt Rotor and other projects under the Clean Sky 2 Joint Undertaking are highlighted.

Airbus’ powerplant integration expertise to play an important role in optimising the fuel efficiency gains of Rolls-Royce’s UltraFan engine demonstrator.

The facility is developing carbon fiber composite fan blades and fan cases for the Rolls-Royce UltraFan jet engine demonstrator.

CFRP blades and fan case cut weight for twin-engine aircraft by 700 kilograms