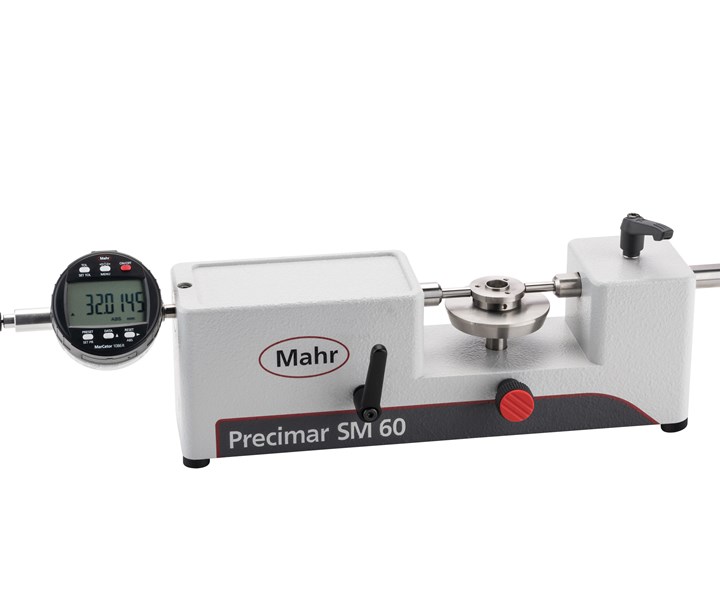

Mahr's Precimar SM 60 speeds length measurement

The SM 60 is a length measurement system with a measuring range of 60 mm, and is configurable with Mahr readouts such as digital indicators or LVDT probes.

Source | Mahr

Mahr Inc.’s (Providence, R.I., U.S.) Precimar SM 60 is a length measurement instrument designed for fast and precise external measurements on shop floor parts. The SM 60 is said to have a measuring range of 60 mm and to be configurable with Mahr readouts such as digital indicators or LVDT probes. It incorporates a 25-mm sensitive contact and a fixed reference jaw with a 35-mm adjustment to obtain its full 60-mm measurement capacity.

According to the company, the SM 60 is designed for high-performance gaging at the point of manufacture, and is easily adaptable for new workpieces, enabling the system to act either as a long-range measuring system or as a high-performance comparator for sub-micron applications.

The user selects the preferred readout for level of performance and application of the measurement. For applications requiring versatility, a 25-mm MarCator 1086 or 1087 is available, featuring a large display or analog dial. If higher resolution and performance are required, a Millimar P2004 LVDT with ±2-mm range and C1200 bench amplifier are available to provide sub-micron performance at the machining process.

The SM 60 also features integrated coupling to protect against over-range damage, hardened contact surfaces on both the sensitive and reference contacts, and an easy-to-adjust support table and optional floating micro-center support. For increased versatility, a family of measuring attachments for the standard contacts is available, including contacts with radius surfaces, flat-edge contacts and flat contacts with various diameters, allowing for plain OD checks for adding gage pin wires, OD thread checking and a threaded contact set for adding any of Mahr’s standard M 2,5 threaded contacts.

Related Content

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)