Kordsa targets phenolic-based sandwich panel toward aircraft interiors

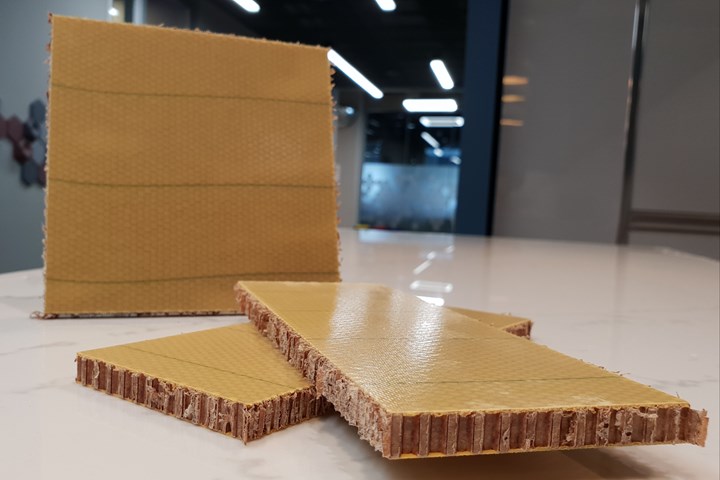

The sandwich panels comprise glass fiber/phenolic skins surrounding a Nomex honeycomb core.

Source | Kordsa

Tire, construction reinforcement and composites technologies company Kordsa (Izmut, Turkey) has introduced a new line of honeycomb composite sandwich panels for the cabin interior of commercial airplanes. The company’s Composites Center of Excellence (CTCE), founded in 2016, played a significant role in the development of the technology. The material, comprised of glass fiber in a phenolic matrix surrounding a honeycomb core, is targeted toward aircraft galley applications. Kordsa selected phenolic for its flame-retardancy. The honeycomb core, provided by Advanced Honeycomb Technologies (San Marco, Calif., U.S.), a subsidary of Kordsa, is also phenolic-based. Each honeycomb cell is hexagonal-shaped and measures 3.2 millimeters wide. Kordsa says its composite sandwich panels can withstand greater bending loads than the leading brand and is able to withstand peel loads in either direction.

Related Content

-

The AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

Assembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.