JEC World 2020 preview: Anaglyph

Composites design and manufacturing solutions specialist Anaglyph is demonstrating the latest versions of its suite of software.

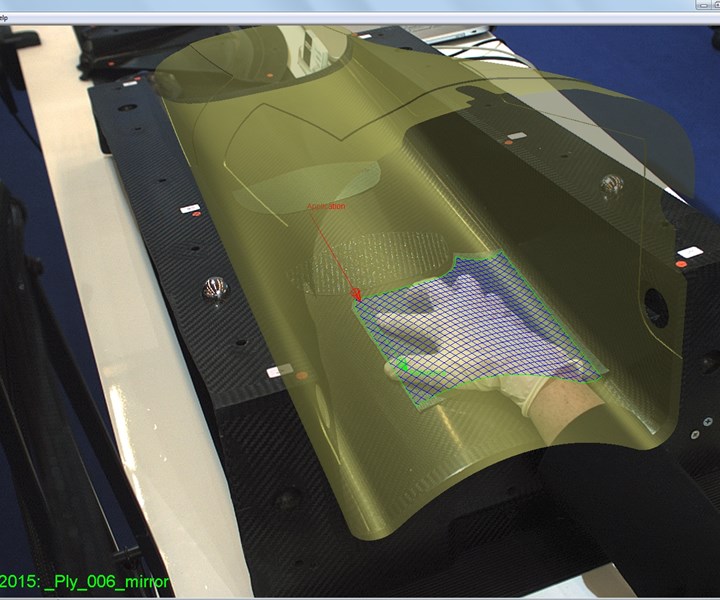

Anaglyph PlyMatch software for hand layup of composites. Source | Anaglyph

Composites design and manufacturing solutions specialist Anaglyph (London, U.K.) is demonstrating the latest versions of its suite of software. The first is PlyMatch, which uses augmented reality to show the live combined images of actual and target ply outlines and fiber orientation details on a monitor, so that the two can be matched by the operator. PlyMatch is used for the accurate placement of plies in hand layup manufacture of composite parts, as well as for monitoring and validation of automated methods. It is particularly useful in case of complex geometries, with high curvature or enclosed spaces.

Second is Laminate Tools, a standalone Windows application, interfacing with most industry standards. It addresses the entire design-analysis-check-manufacture group process of structural design, but focusing on the composite material features. It complements existing CAD systems and/or FEA environments. Laminate Tools has native interfaces to SOLIDWORKS, Rhino, Nastran, HyperMesh, Ansys and Abaqus. It helps optimize and manufacture what is being designed.

Third is CoDA (Composite Component Design Analysis), used for preliminary analysis sub-components with plate, beam, joint, flange or laminate geometries.

Fourth, based on Classical Laminate Theory, is LAP (Laminate Analysis Program), used to analyze any type of composite laminate subjected to in-plane loads and moments. The flat laminate is no fixed size, apart from its thickness, so that the analysis can be applied to any composite component where loadings and deformations are known.

Related Content

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

CFRTP enables better, greener smartphones

Carbon Mobile’s “monocoque” design eliminates separate case, cover and frame, better protects electronics and simplifies disassembly.