JEC World 2019 preview: 3A Composites

3A Composites Core Materials (Sins, Switzerland) is launching its reformulated AIREX T92 core, as well as its BALTEK SealX and Adaptive ContourKore balsa cores.

3A Composites Core Materials (Sins, Switzerland) is launching its reformulated AIREX T92 core, as well as its BALTEK SealX and Adaptive ContourKore balsa cores.

The reformulated AIREX T92 now contains recycled PET bottles as its raw material instead of virgin PET, which reportedly makes the product more sustainable while keeping the same level of performance. The product’s specific mechanical properties and resin uptake — reportedly unchanged after the material change — are intended to give the T92 high value in terms of performance as well as cost.

According to the company, balsa wood is the best universal core material in terms of mechanical properties, weight and cost. However, its naturally higher resin uptake can be a weakness.

BALTEK SealX is meant to eliminate the gap between foam and balsa core for resin uptake, reportedly reducing resin uptake by more than 80% for rigid panels and 50% for flexible panels and setting a new industry benchmark. SealX has been externally tested and approved by DNV-GL.

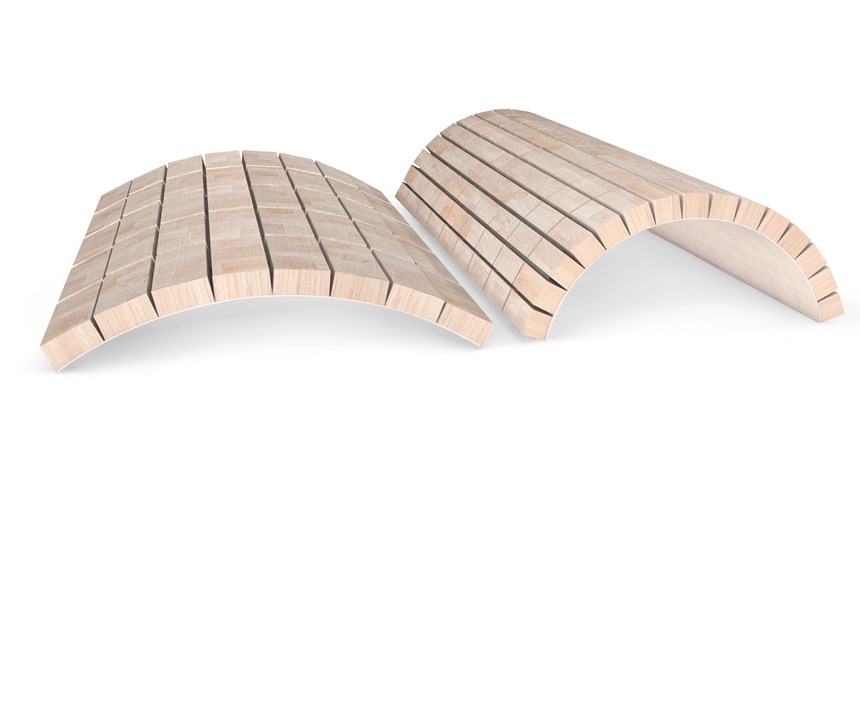

BALTEK Adaptive ContourKore is a balsa finishing option designed to optimize resin uptake and drapeability, further reducing resin uptake. With this product, 3A Composites Core Materials attempts to end the current “one-size-fits-all” strategy that has dominated the balsa market.

The combination possibilities of BALTEK SealX with the Adaptive ContourKore and 3A Composites’ density portfolio are meant to allow mass customization in engineering the optimal core material system while ensuring low total cost of ownership and high performance.

Visit 3A Composites Core Materials at JEC World 2019 at Stand G33 in Hall 5.

Related Content

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Carbon fiber in pressure vessels for hydrogen

The emerging H2 economy drives tank development for aircraft, ships and gas transport.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

.jpg;width=70;height=70;mode=crop)