CAMX 2021 preview: Michelman

Michelman, a manufacturer of advanced materials including fiber sizing and surface modifiers, is featuring its Hydrosize and Hydrosize Carbon fiber sizing solutions, and Unyte technologies for technical textiles.

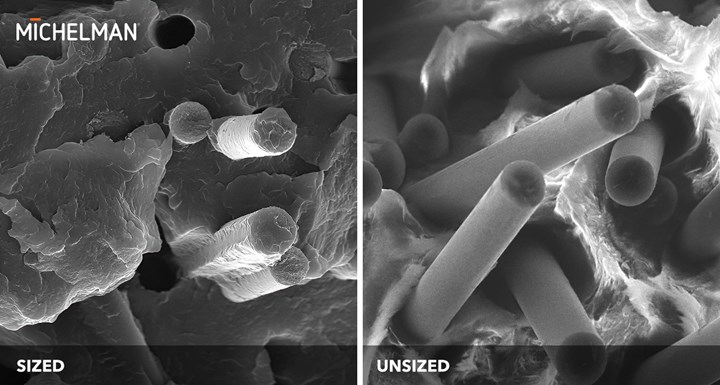

Micrographs of sized and unsized fibers. Photo Credit: Michelman

Michelman (Cincinnati, Ohio, U.S.), a manufacturer of advanced materials including fiber sizing and surface modifiers used to produce reinforced plastic composites, is featuring its Hydrosize and Hydrosize Carbon fiber sizing solutions, and Unyte technologies for technical textiles. Hydrosize is Michelman’s flagship line of sizing solutions designed for use in the manufacture of glass, carbon and natural fibers, including chopped and continuous formats. They are used as lubricants, film formers, sizing agents, and binders during fiber manufacturing and composites processing. This technology allows fiber manufacturers to optimize the interfacial adhesion between polymers and fibers by tailoring the surface chemistry of reinforcement fibers to the chemistry of the matrix resin.

Michelman also will feature its line of Hydrosize Carbon solutions that allow the composites industry to leverage carbon fiber’s unique benefits of high strength and stiffness and help it further exploit the traditional benefits of composites: design freedom, consolidation of parts and integration of functionality. Composites that require high-temperature processing typically require the use of high-temperature polyamide, polyimide, PPS and PAEK based resins. Select Hydrosize Carbon grades are said to provide excellent thermal stability and are specifically designed to withstand elevated processing and service temperatures. Furthermore, the series of grades offers a variety of solutions depending on resin compatibility, fiber type and targeted composite performance.

Michelman’s Unyte brand is a family of water-based technologies that help achieve advanced form and function in woven and nonwoven materials used in the design of technical textiles and prepreg fabrics. These solutions enhance textile products' performance by improving adhesion, binding, processability and chemical and heat resistance. The Unyte Bind series offers multiple solutions that improve fiber-to-fiber adhesion. Unyte Grip is designed to promote the adhesion between fibers and polymeric matrices to improve various functional or mechanical properties. Unyte Slip is designed to work with fabrics, nonwovens and prepregs that need to be stacked or rolled without sticking together. Finally, Unyte Resist products are designed to provide wetout and moisture/chemical resistance to fabrics. They impart performance benefits, including chemical resistance, water resistance, and hydrophobicity under humid conditions to fabrics, wovens and nonwovens.

Visit Michelman in booth #S48Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

Composite lamination equipment, laminator belts

CAMX 2023: Schott & Meissner, Kastilo and Held Technologie join Allertex of America in featuring double belt presses, high-quality laminator belts and more.

-

What to expect at CAMX 2022

The Composites and Advanced Materials Expo (CAMX), the largest composites industry trade event in North America, takes place Oct. 17-20, 2022 in Anaheim, Calif., U.S.