CAMX 2021 exhibit preview: Calyxia

Calyxia's microencapsulation technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions.

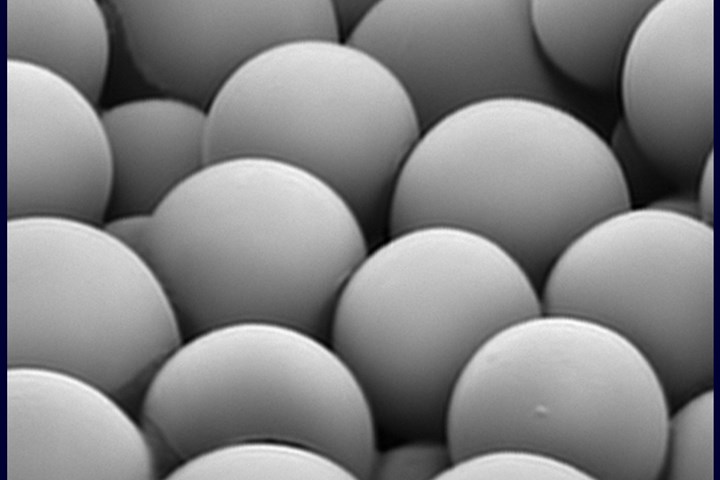

Calyxia (Bonneuil-sur-Marne, France) has developed a microencapsulation technology and process to produce what the company says are the first sealed, process-resistant and customizable microcapsules. According to Calyxia, this technology expands the performance potential and the scope of use of specialty chemicals.

Calyxia says its technology can protect reactive, functional and optical additives even in extreme temperature and shear processing conditions (extrusion, injection, compression molding, film casting).

More specifically, Calyxia technology can protect process additives (catalysts, accelerators, curing agents) from premature reaction during processing, and then deliver the additive on command during curing. This reportedly provides a significant advancement in terms of process and performance control. In addition, the Calyxia technology can protect functional additives (anti-wear, anti-abrasion) against degradation, cross-reaction or instability during processing. Anti-wear/abrasion additives are then delivered only in the event of wear or abrasion. Calyxia says functional additives enhance both the performance and the lifetime of the final product. Calyxia’s microencapsulation technology is also able to fully protected optical additives (pigments, liquid crystals, dyes) throughout the lifetime of the product.

Calyxia says its microencapsulation technology has been successfully validated with many large actors in high-performance plastics, electronics materials, adhesives and coatings applications to provide new features to materials or improve the performance of current materials.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

-

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

-

Download today's CAMX 2022 Show Daily: Tuesday, Oct. 18

Download today’s news reported live by CW on the CAMX show floor in Anaheim, California. Headlines cover this morning’s keynote, Michael Steep, Good Day, CAMX, ACE/CAMX award finalists and more.