Digital composite cutting, kitting made clean, simple and productive

CAMX 2023: Zünd is exhibiting its heat-sealing module in operation with a G3 cutter configuration and Robot PortaTable 130 to emphasize its fully digital cutting capabilities from prepreg to thermoplastics.

Zünd America (Oak Creek, Wis., U.S.) is once again inviting visitors to experience the many ways digital cutting workflows can be tailored to the specific, challenging demands of composites manufacturing. From prepreg to thermoplastics, Zünd says it offers tools for any material, making the cutting process clean, precise and efficient.

Highlighted at its booth is the company’s award-winning heat-sealing module (HSM). Introduced at last year’s CAMX, the HSM tool for Zünd digital cutting systems aims to solve the challenges of processing thermoplastic composites — particularly their fraying properties which lead to fragile, irregular edges.

When mounted on a Zünd digital cutter, the module uses hot air to heat-seal the perimeter of a part prior to cutting. Driven by a fully digitally controlled process, the Zünd software directs the module over the composite material, sealing the fibers around each part’s edges. In a next step, the high-performance power rotary tool (PRT) cleanly cuts the material without leaving any uncut or loose fibers behind. This enables fully unattended cutting automation, the company notes, and once the seal and cut operations are completed, the processed parts benefit from complete stability and ease of handling.

Zünd contends that the HSM tool facilitates and drastically improves clean cutting and handling of dry fiber materials with thermoplastic content, thus overcoming major, industry-wide challenges and enabling more widespread use of these materials.

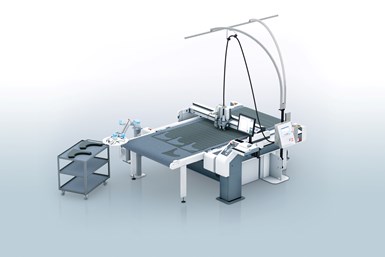

The HSM tool will be shown in operation on a Zünd G3 cutter configuration in conjunction with the Robot PortaTable 130, another Zünd automation solution consisting of a roller table (for easy changeovers to other Zünd cutting systems) equipped with a collaborative robot (cobot) for fully automated parts kitting and sorting. This solution, too, is designed to make processing composite materials quick, easy and productive.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

-

Five-axis CNC machining center delivers on versatile materials processing needs

CAMX 2023: Biesse America highlights the Rover Plast A FT, capable of adaptable milling and cutting operations for plastics and composite materials with high precision and a quality finish.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

.jpg;maxWidth=300;quality=90)