Avient presents Hammerhead sandwich panels for boatbuilders

Continuous glass fiber-reinforced thermoplastic panels offer the marine industry lightweighting and production efficiency compared to traditional construction materials.

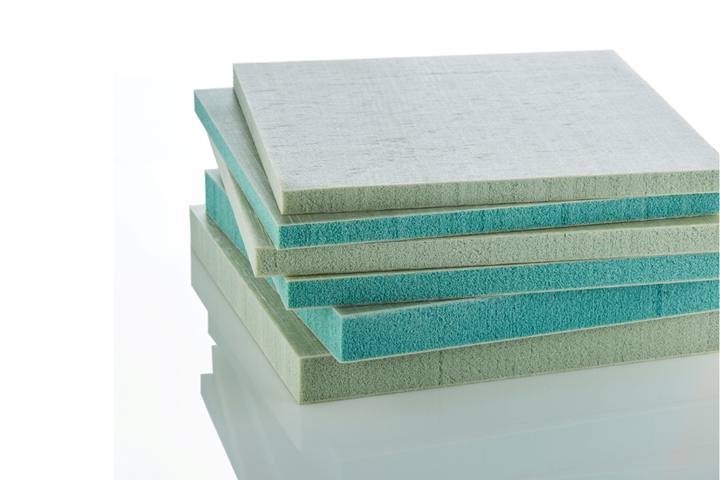

Avient Corp. (Avon Lake, Ohio, U.S.) is featuring Hammerhead marine composite panels. With more than 50% weight savings compared to plywood, these continuous fiber-reinforced thermoplastic composite sandwich panels are said to offer boat manufacturers a light, more efficient alternative to traditional marine construction materials.

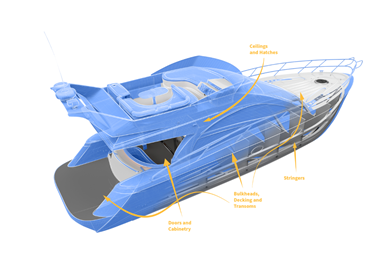

Beyond weight reduction, Hammerhead panels improve installation and labor productivity, replacing typical wood, hand layup and vacuum-assisted processes with a consolidated, ready-to-install panel. Applications range from structural to cosmetic in bulkheads, decking, ceilings, hatches, covers, cabinetry, fittings, transoms and stringers.

Hammerhead marine composite panels are made from continuous glass fiber-reinforced thermoplastic face sheets and polyester foam cores. This configuration provides strong adhesive properties that can improve bonding to various structural materials and to coatings and surface films for increased design flexibility. Resistant to moisture degradation and rot, Avient says the panels can also withstand harsh marine conditions. Panels are available in various thicknesses and core densities, customized to specific uses and applications.

“We developed Hammerhead panels as an alternative to marine plywood and other materials to help boatbuilders solve a variety of manufacturing challenges, like reducing VOC [volatile organic compound] exposure and improving labor and installation times,” Mike Mosley, general manager, advanced composites at Avient, says.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

.jpg;maxWidth=300;quality=90)