Adhesives, sealants meet aerospace and defense specifications

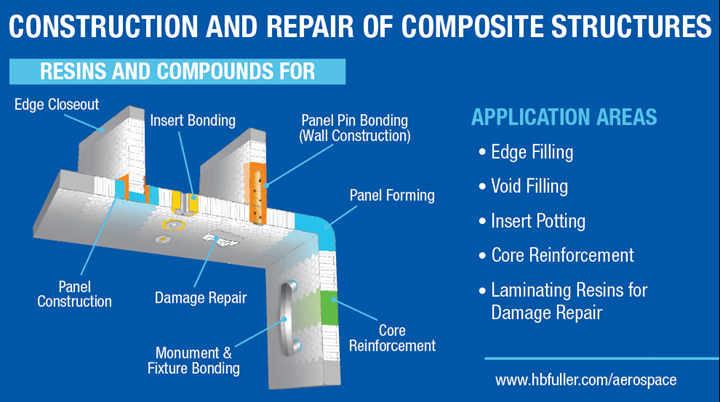

CAMX 2023: H.B. Fuller Aerospace manufactures, packages and delivers a variety of sealants, structural adhesives, low outgassing epoxy systems and more to industry and customer requirements.

H.B. Fuller Aerospace (Irvine, Calif., U.S.) manufactures, packages and delivers adhesives and sealants that are reported to exceed the performance specifications and on-time delivery requirements of commercial aviation, defense and space customers around the world. H.B. Fuller’s adhesive and sealant product offerings include, but are not limited to, low-density edge and void fillers, composite assembly and repair solutions, structural adhesives, self-extinguishing and flame-retardant options, electrically conductive materials, thermally conductive adhesives and electrically insulative high-performance adhesives, as well as lightweight rapid-cure sealants.

H.B. Fuller’s portfolio of access door, fuel tank, rapid cure and environmental-grade sealants is qualified to AMS3265, AMS3281, AMS8802 and many OEM specifications. The company’s newest chromate-free, corrosion-inhibitive, REACH-compliant sealant is available now in B-1/2 and B-2 applications and retains high performance characteristics at temperature excursions up to 360°F.

H.B. Fuller’s line of structural adhesives for composites and metal bonding features three products: EY3010, a flame-retardant, low-density (0.58 g/cc) adhesive that is self-extinguishing per FAR Part 25.853, and offers 5,000 psi compressive strength for insert potting applications. EY3010 is well suited for interior applications where honeycomb panels are used. EY0540-0043 is an unfilled, two-part, medium-viscosity laminating system for use in high-temperature plastic tools. UR4515G is a high lap shear strength, non-conductive, non-corrosive structural polyurethane.

H.B. Fuller’s low outgassing epoxy systems are said to meet NASA outgassing requirements, are “gyro-grade,” and exhibit optimized chemical resistance and low coefficient of thermal expansion. Flexobond 442, for example, is thermally conductive and has a specific gravity of 2.0, making it ideal for bonding or filling glass diodes or sensitive components. LCA-4 is a highly filled gyro-grade epoxy adhesive for high-reliability electronic assembly. It’s proved useful in applications requiring bonding or hermetic sealing of metal, ceramic, glass and other substrates.

H.B. Fuller’s chemists have decades of experience formulating aerospace adhesives and sealants, and specialize in the development of custom formulations to meet customer’s specific needs.

Related Content

-

CAMX 2022 exhibit preview: Scott Bader

Scott Bader North America showcases its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling systems.

-

Composite lamination equipment, laminator belts

CAMX 2023: Schott & Meissner, Kastilo and Held Technologie join Allertex of America in featuring double belt presses, high-quality laminator belts and more.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.