Vega VV16 rocket launches with Bercella composites dispenser structure onboard

The CFRP dispenser structure, developed for the Small Spacecraft Mission Service (SSMS), was successfully launched for the European Space Agency.

Photo Credit: ESA

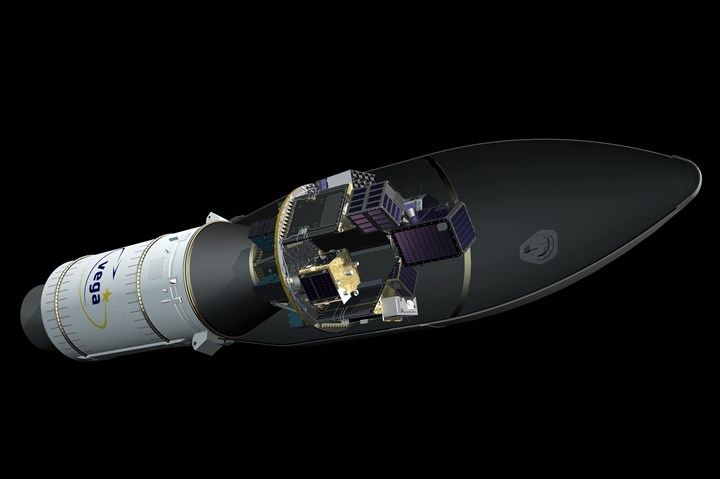

On Sept. 3, composites specialist Bercella Srl (Varano de’ Melegari, Italy) reported the Vega VV16’s successful launch of the Small Spacecraft Mission Service (SSMS) from Kourou Space Center in French Guiana. The rocket also carried into orbit the carbon fiber-reinforced plastic (CFRP) dispenser structure developed by Bercella for SAB Aerospace s.r.o. (Czech Republic), loaded with more than 50 microsatellites, the structural parts of one of which were also manufactured by Bercella.

According to Bercella, the European Space Agency’s (ESA) Vega program provides an answer to the increasing commercial demand for small satellites. The flight aims at demonstrating the technical and financial feasibility of “rideshare” opportunities for small satellites being launched at once from a single modular architecture in order to split launch costs.

The SSMS dispenser is said to consist of a modular architecture, aimed at hosting multiple combinations of small satellites at once. This includes a hexagonal lower section, with two deployers for nanosatellites on each side, for a total amount of 12 deployers and 46 Cubesats in total, and an upper section capable of hosting various configurations of micro-, nano- and mini-satellites, namely seven microsatellites for this launch.

The SSMS system is made from several large sandwich panels with full carbon-fiber composite skins. The skins use Toray RS-36, an epoxy-based composite material reinforced with Toray M55J high modulus carbon fiber, which provides strength, stiffness and stability for the overall structure; the materials were supplied by Toray Advanced Composites’ European Centre of Excellence for thermoset systems in Langley Mill (Nottingham), U.K. According to Bercella, the SSMS dispenser structure was designed by SAB Aerospace s.r.o and commissioned to Bercella for Italian aerospace company Avio S.p.A. (Rome, Italy) due to Bercella’s experience on large structures for the space industry and commitment on optimum performance and lead times.

"We are proud for our contribution to this milestone for the European space industry. We welcomed the challenge with enthusiasm, putting at ESA’s disposal our process expertise and strong materials know-how. We are ready to strengthen Italy’s participation in the space market evolution, and contributing as a key European player for composites structures for space,” says CEO Massimo Bercella. “We praise ESA's willingness to support European SMEs in this important step forward. SAB’s high professionalism, together with the commitment of all players involved, helped managing such a complex project.”

According to the company, the ambitious multiplayer project requested significant risk mitigation and process control, that Bercella provided via its integrated manufacturing efforts and in-house industrialization capabilities. Further, the project’s challenging size was managed through Bercella’s manufacturing facilities, in addition to a four-meter diameter autoclave and large CNC equipment. The project also gave Bercella the opportunity to upgrade its internal lab with state-of-the-art testing equipment, including an ISO 8 clean room.

Throughout the multi-year project, Bercella says it produced and tested almost 1,000 samples for materials and processes qualification, built and assembled the flight panels introducing, which are said to have improved performance optimization in the 2.5-meter diameter main deck and transformed its initial four-part design into a single-piece creation.

Related Content

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreOne-shot manufacture of 3D knitted hybrid thermoplastic composite structures

MAPICC 3D project replaces steel seat support in heavy-duty vehicle with a 3D knitted composite made from thermoplastic hybrid yarns comprising the matrix and reinforcing components.

Read MoreClemson Composites Center: Working with industry to transform composites

Offering liquid and thermoplastic composites molding, LCA-weighted simulation, full testing to validate materials/process data cards, CCC’s digital life cycle approach unites manufacturing, microstructure, part property map and structural analysis.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More