The Native Labs launches new course on monocoque structural analysis

The online, self-paced course breaks down underlying concepts, shares industry-related know-how, ultimately enabling students to conduct a full structural analysis of a carbon fiber monocoque.

Structural analysis, applicable to real-life cases involving composites and related to the automotive sector, isn’t always something that can be learned at a university — more often than not, it is learned on the job with all the difficulties it entails. After a wide request, The Native Lab (TNL, Madrid, Spain), Managing Composites’ training division, has decided to launch a course on the topic. The idea is to transmit how to conduct the full structural analysis of a carbon fiber monocoque through the sharing of industry-related know-how.

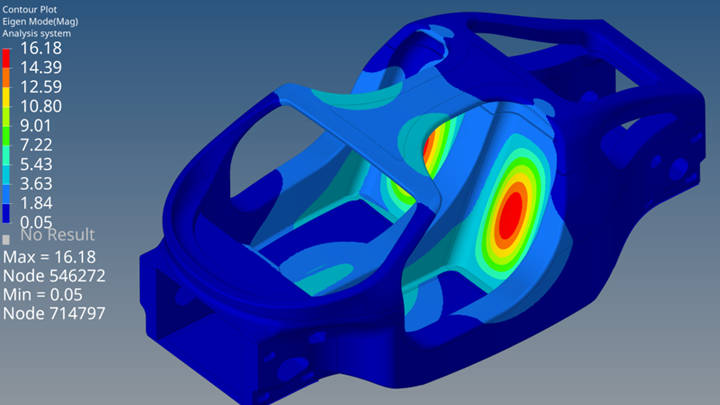

According to TNL, the aim for the Monocoque Structural Analysis course is to provide students the know-how to carry out the simulation from scratch —through an understanding of underlying concepts of finite element analysis (FEA) and material science — and after that be able to take into account all the essential things (explained in more detail below) in order to receive reliant results.

In the first part the course, instructors will explain implicit versus explicit analyses and their use, the vertical asymmetric load case and the simplified structural surfaces method. Moreover, the course discusses how to create a composite material card, how to define the layup, what composite failure criteria there are, how honeycomb modeling is done, as well as laminate optimization.

Once these essential concepts have been discussed, the actual process of simulating the monocoque will be undertaken. Meshing, material orientation, layup creation, among others, will be the first items to take into account. Once modeling has been explained, the different analyses will be carried out, such as typical loading scenarios, inertia relief and torsional stiffness. Finally, what TNL says is the the more spectacular part on impact dynamics (crash) is discussed.

Course participants will be able to learn with and from Ignacio Carranza, the CAE manager of Managing Composites and previous research engineer at McLaren Automotive (Woking, U.K.) and stress engineer at Hyundai Motorsport (Alzenau, Germany). All the course is online and self-paced, with the opportunity to send questions to the trainer. On completion every student will get a certificate, have the opportunity to join the ever-growing alumni network and will have access to all course materials for one year.

Currently a 20% discount is running until the end of September 2022, for the first 20 people that sign up. The coupon code is: MSA20OFFER.