Graphene-enhanced prepreg launched for lightning strike protection

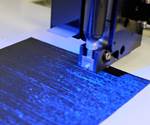

Haydale's range of graphene-enhanced prepreg materials utilize functionalized nanomaterials to improve the electrical conductivity in aerospace applications.

Source | Haydale

Haydale (Ammanford, U.K.) has launched a range of graphene-enhanced prepreg material for lightning strike protection, utilizing functionalized nanomaterials to improve the electrical conductivity. The material can be used for structural components or for enclosures for electronic avionics systems.

According to Haydale, the material also has potential applications for unmanned aerial vehicles (UAV), commercial aviation or space applications, or offshore wind turbine blades.

The material has been developed in collaboration with Airbus UK (Bristol), BAE Systems (Farnborough, U.K.), GE Aviation (Evendale, Ohio, U.S.) and Element Materials Technology Warwick Ltd. (Warwick, U.K.), within the U.K.’s National Aerospace Technology Programme (NATEP)-supported GraCELs 2[1] project, where the first iterations of materials were developed and subjected to lighting strike tests. The consortium is now looking to manufacture a demonstrator component using the developed materials to establish composite manufacturing protocols for commercial purposes.

An electrically conductive masterbatch is also commercially available, and the Haydale team has been working with customers to test the capability achieving significant results over existing materials.

Related Content

-

Materials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

.jpg;width=70;height=70;mode=crop)