FAURECIA to supply hydrogen storage systems for 1,600 Hyundai heavy-duty trucks

Delivery of 10,000 composite tanks proves industrialization strategy of 20% lower weight, 50% lower cost components

Faurecia (Nanterre, France) was recently awarded a significant contract for fuel cell electric vehicle storage systems from Hyundai Motor Company (Seoul, South Korea). Faurecia will supply the entire hydrogen storage system, which will result in delivery of 10,000 composite hydrogen tanks. These will be produced in its global center of expertise dedicated to hydrogen storage systems in Bavans, France.

Faurecia deliveries will begin in 2021, and over a four-year period, will equip roughly 1,600 Hyundai heavy duty trucks that will be delivered to Hyundai Hydrogen Mobility (Zurich, Switzerland), a newly created joint venture between Hyundai and H2 Energy to spearhead hydrogen mobility in Europe.

“Fuel cell electric vehicle technology will become significant in the powertrain mix in the next ten to fifteen years, in particular for commercial vehicles,” says Faurecia CEO Patrick Koller. “Faurecia is investing significant resources in optimizing the potential of this technology and creating the best-in class ecosystem to accelerate its deployment. This award, along with the joint venture we have created with Michelin to offer a unique range of hydrogen fuel cell systems, is a major step in our commitment to become the leader in fuel cell systems.”

Lighter, less-costly composite tanks

Faurecia announced in 2017 that it had acquired an exclusive access to the intellectual property and process know-how of composite hydrogen tanks from STELIA Aerospace Composites (Toulouse, France). With this support, Faurecia has been able to design, industrialize and commercialize high pressure hydrogen tanks made of carbon fiber composites for fuel cell electric vehicles (FCEVs).

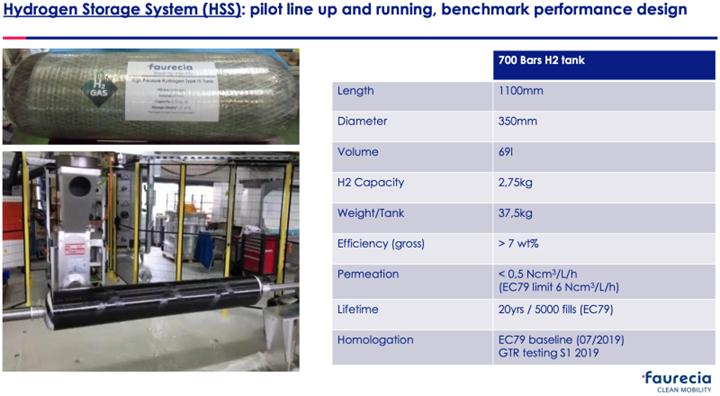

According to a March 2018 press release by STELIA Aerospace Composites, it has specifically helped Faurecia develop a lightweight and cost-effective 700 bar hydrogen storage tank. In the video below, Nils Walther, global program manager for Faurecia’s zero-emissions fuel cell division, shows this tank as well as Faurecia’s 350 bar composite tank at CES 2020 (Consumer Electronics Show, Las Vegas, Nev., U.S). He explains that pilot lines in France are already in production and notes Faurecia’s pride in achieving 15-20% weight reduction, which allows it to use less carbon fiber, for less raw material cost, plus less filament winding time, while providing more interior volume for higher driving range.

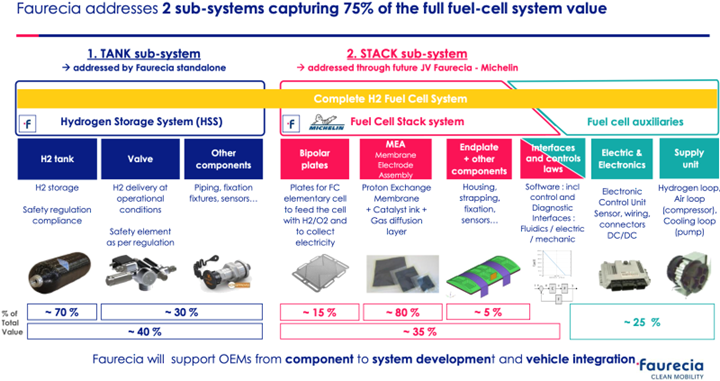

These weight and cost achievements are fulfilling the strategy explained by Faurecia chief technical officer Christophe Aufrère:

“We want to accelerate the development of hydrogen through different ways. The first one is massive investment of 15-20 million euros in R&D and pilot lines. The second one is that we want to halve the price of the main components and we are providing 80% of the value chain. The third one is, of course, we want to also massive deploy this technology in terms of industrialization.”

Global center of excellence

In June 2019, Faurecia announced the creation of a global center of expertise for hydrogen storage systems at its R&D center in Bavans, France. The center, scheduled to start operations in the second-quarter 2020, represents a total investment of approximatively €25 million. Faurecia plans to add 50 jobs to the nearly 750 employees at the site, which is dedicated to Faurecia’s Clean Mobility activity.

Fuel-cell electric vehicles offer an attractive and complementary alternative to battery-electric vehicles. The range and refueling time of fuel-cell trucks should be equivalent to diesel ones while being completely emissions-free. By 2030, it is estimated that at least 2 million new vehicles, and more than 350,000 commercial vehicles, will be equipped with fuel cell technology, according to Faurecia.

Related Content

Spanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

Read MoreAZL launches three Joint Partner Projects, welcomes composites leaders participation

New initiatives kicking off mid-July 2025 explore fire testing safety for EV battery cases, holistic TPC pressure vessel strategies and exploring and quantifying composites in space and defense.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreComposites end markets: Automotive (2025)

Composites manufacturing intelligence drives circular economy solutions as automotive industry balances technical demands with sustainability mandates.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More