Coriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

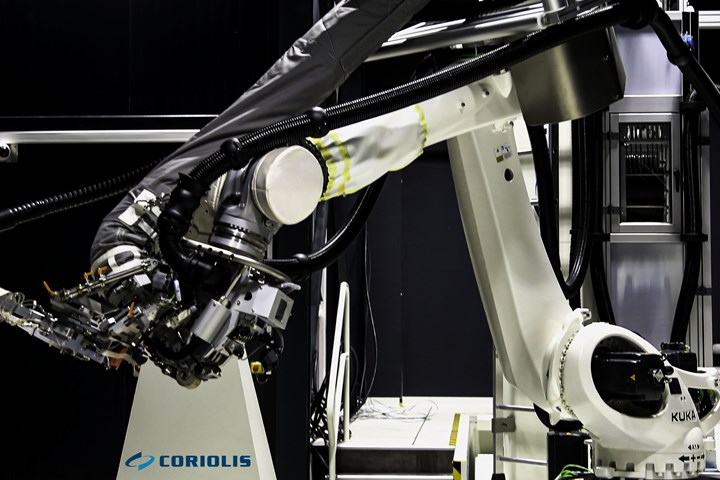

Coriolis Composites (Quéven, France) is pleased to announce the installation of its C1 automated fiber placement (AFP) system at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) at Sabanci University (Istanbul, Turkey). This Coriolis C1 robot with 8-meter linear axis, a 6-ton headstock tail stock and six-kilowatt laser will be used in SU IMC’s technology development for applications in advanced thermoset and thermoplastic composites part manufacturing, especially for the aerospace and automotive industries. It can accommodate molds up to 6 meters long and 3 meters in diameter.

The C1 is a versatile AFP machine ideal for R&D applications using thermoset, dry fiber and thermoplastic materials. It features a compact head to lay up on concave and convex tools, as well as complex parts with a narrow radius. This flexibility is aided by its light robot base versus a heavy gantry, as well as the carbon fiber spool embedded in the head.

SU IMC is an industrial-scale R&D and open innovation center focused on advanced polymer composites and additive manufacturing (AM) technologies. According to Coriolis Composites, it provides value-added solutions and technology transfer for advanced manufacturing, including:

- Design and analysis

- Prototyping and product development

- Research and application

- Professional training

- Manufacturing and test services.

SU IMC is using the C1 system for material testing and manufacturing of demonstrators.

Related Content

-

Nine factors to consider when designing composites cure tooling

Gary Bond discusses the common pitfalls and compromises when designing good cure tooling and their holistic significance for a robust composite production process.

-

Collins Aerospace demonstrates new thermoplastic composites capabilities

Collins Aerospace in Almere has produced a 7-meter raceway for the Clean Sky 2 MFFD lower fuselage using novel CCM and tooling technology while the Riverside facility in the U.S. advances AFP and welding as part of global strategy for more sustainable airframes.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.