Adapa announces Curve Works as new co-investor

Curve Works owner Dr. François Geuskens is taking a proactive management role as Adapa’s CTO to continue broadening the functionality, application of the company’s adaptive mold system.

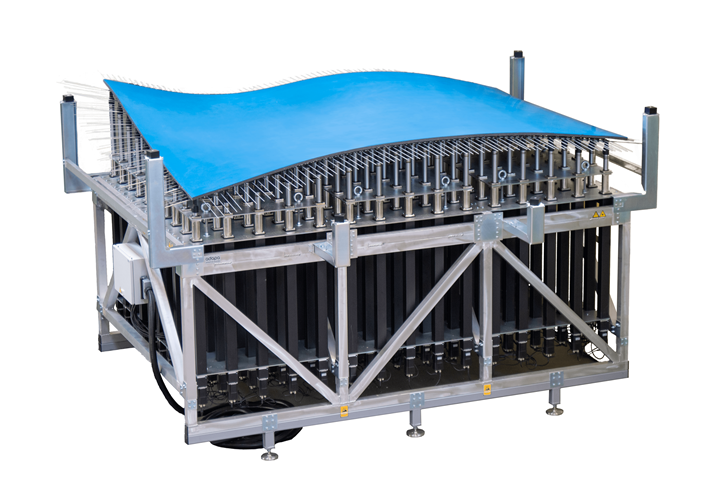

Adapa A/S (Aalborg, Denmark), known for its reconfigurable mold system, has extended ownership of the group with composite material specialist Curve Work Holdings (Alphen aan den Rijn, The Netherlands), a new co-investor.

Curve Works Holding BV owners Dr. Tahira Ahmed and Dr. François Geuskens have built extensive knowledge of Adapa’s adaptive mold technology over the last seven years. Ahmed and Geuskens have used Adapa’s technology to pioneer new products and production technologies using composite and wood materials.

Geuskens expects to take a proactive role in Adapa’s management in his new position as chief technology officer (CTO).

“Having Francois on board will increase our competency to serve the growing composites market as well as broaden the functionality and application of our adaptive molds,” Adapa’s chairman of the board, Jens Broberg, notes.

Geuskens hopes to transform Adapa into a total solutions provider for customers that are investing in future-proof sustainable technologies. “The adaptive mold is, without a doubt, a key technology toward achieving their goal,” he says.

Related Content

-

Metal AM advances in composite tooling, Part 1

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

-

Materials & Processes: Tooling for composites

Composite parts are formed in molds, also known as tools. Tools can be made from virtually any material. The material type, shape and complexity depend upon the part and length of production run. Here's a short summary of the issues involved in electing and making tools.

-

Metal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

.jpg;maxWidth=300;quality=90)