Automation

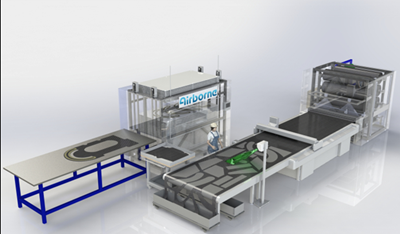

Airborne to supply composites cutting/kitting equipment to Airbus Helicopters

Fully digital Kit by Light systems will enable faster, simpler and more efficient composite ply management at Airbus’ Donauwörth facility.

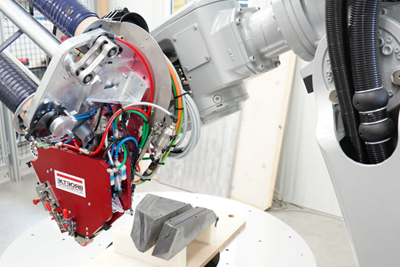

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreAutomated end-to-end composite solutions for tape laying, fiber placement

JEC World 2024: Fives invites attendees to learn more about its specialization in providing composites precision and performance, whether its through its Cincinnati, Forest-Liné and Lund lines or its ACE and COAST engineering suites.

Read MoreFilament winding software focuses on efficiency, precision

JEC World 2024: Roth Composite Machinery is co-exhibiting with partner mefex GmbH to present new developments to its µRoWin software for automated filament winding.

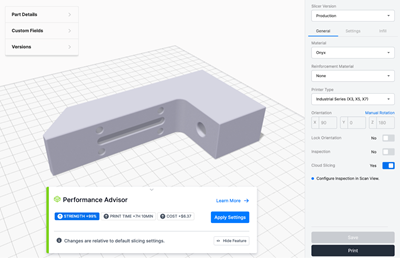

Read MoreMarkforged optimizes 3D-printed part performance with Performance Advisor

The physics-based analysis method is use case independent, automatically providing print settings that will give users options to increase part strength while optimizing for cost and print time.

WatchRein4ced, Dieffenbacher automate large-scale production of CFRP bike frames

A synergistic alliance combining Dieffenbacher’s production automation with Rein4ced’s hybrid Feather composite led to fully automated bike frame production line, which will be expanded to other composite products.

Read MoreComposites end markets: Boatbuilding and marine (2024)

As the marine market corrects after the COVID-19 upswing, the emphasis is on decarbonization and sustainability, automation and new forms of mobility offering opportunity for composites.

WatchIntelligent, automated production methods for composites cutting, logistics

JEC World 2024: Zünd is highlighting digital excellence via its ZCC Cut Center, heat sealing module (HSM), G3 Cutter and ZPC software.

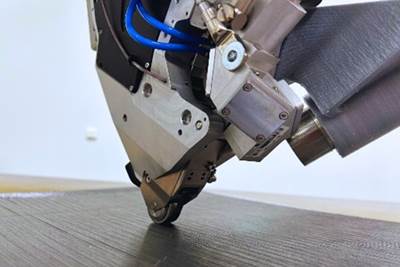

Read MoreCoriolis introduces hybrid CPico AFP machine

This compact cell brings together 3D printing, AFP and milling aided by a comprehensive software program, further simplifying the manufacture of complex thermoplastic composite aerostructures in the future.

WatchFIBRE4YARDS incorporates next-gen composites technologies to redefine shipbuilding

At the project’s completion, consortium members have unveiled final results and a 1:1 scale demonstrator, highlighting the opportunities for more collaborative, digitized, automated, efficient and environmentally friendly shipyards.

Watch

.jpg;maxWidth=300;quality=90)