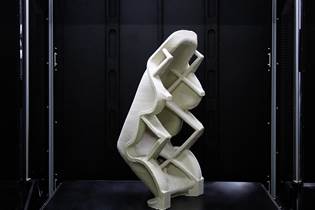

Conventional tooling processes are heavily reliant on manual labor, posing a bottleneck for composites manufacturing. This webinar will introduce a new, digital approach to composites tooling utilizing high-speed additive manufacturing via the award-winning Massivit 10000, which allows manufacturers to shorten tooling workflows from 19 steps down to just four.

Participants will discover how to directly print custom molds, jigs, fixtures, mandrels and plugs and find out how advanced thermosets enable true isotropic molds for high temperatures. Also, learn how to achieve consistent mechanical and thermal properties across all axes, offering a low and consistent CTE and a high HDT up to 150°C. A variety of applications will be explored for the marine, railway, automotive, construction, aerospace, home refurbishments, and sports industries.

Attendees will discover how to:

- Produce isotropic molds suited to high temperatures

- Shorten tooling time by 80%

- Cut manufacturing costs by 75%

- Benefit from advanced thermosets with high mechanical and thermal properties

- Decrease waste of expensive materials