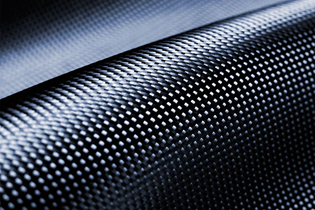

Manufacturing environments create numerous opportunities for contamination. Knowing what contaminants are threatening composite bond strength and reliability, as well as knowing where they are coming from (such as mold release left on a surface), is crucial to putting process controls in place to neutralize damage that can be caused by these contaminants. Quantitative surface quality measurements give manufacturers the proof to know when the surface is clean enough and the ability to monitor changes in cleanliness overtime.

Primary Topics:

- Identification of specific and common contaminants

- Remediation strategies through evaluation of solvent cleaning and abrasion effectiveness

- Quantitative contamination detection techniques

Presenter:

Lucas Dillingham

Aerospace Applications Specialist, BTG Labs

BTG Labs' Aerospace Applications Specialist, Lucas Dillingham, has had 10 years of implementing inspection technology, writing specifications for manufacturing, solving production challenges, and commercializing new inspection technology in a variety of industries. The last three years have been focused on Aerospace bonding, coating, and sealing process development, supply chain control, process troubleshooting, and MRO / Sustainment deployments of BTG Labs’ Surface Analyst surface quality inspection systems.