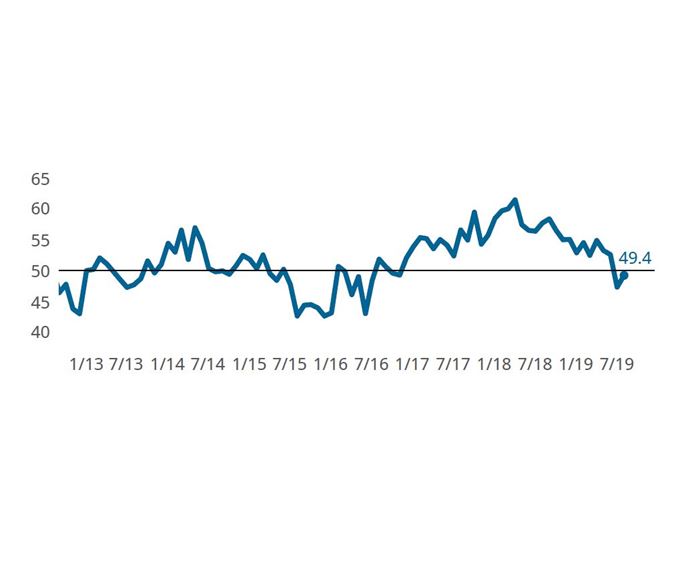

Composites Index contraction slowed in August

The Index indicated expansionary readings in production, supplier deliveries and exports, but was pulled lower by employment, new orders and backlogs.

The Composites Index registered 49.4 in August, which indicates slowing contraction over the prior month. Index readings above 50 indicate expanding activity, while values below 50 indicate contracting activity. The further away a reading is from 50, the greater the change in activity. Gardner Intelligence’s review of the underlying data revealed a surprise expansionary reading in export business activity in August. The Index — calculated as an average of its components — was raised higher by expansionary readings in production, supplier deliveries and exports, and was pulled lower by employment, new orders and backlogs.

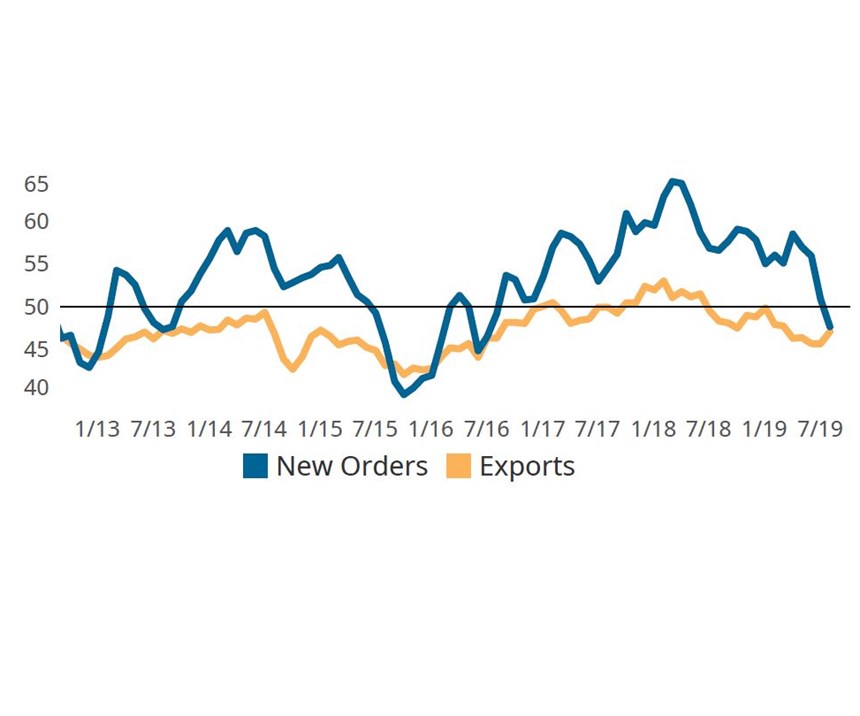

The August Index indicated an unusually large eight-point spread between production and new orders. Since records began in 2011, the spread between new orders and production has often been very small, as fabricators often quickly adjust production to new orders. The combination of increased production despite weak new orders activity was apparent in August’s backlog data, which reported another month of contraction.

Lastly, it should be noted that August’s combination of an expansion in exports coupled with a quickening contraction in total new orders is rare, as it suggests that domestic demand for composite goods contracted during the month. Since mid-2018, the Composites Index has regularly reported the opposite, that contracting exports have typically been offset by expanding domestic demand.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

2022 Farnborough International Air Show highlights

Farnborough, as usual, provided a platform for a variety of announcements in the aerospace, defense and advanced air mobility spaces from companies like GKN Aerospace, Joby, Airbus, Rolls-Royce, Boom Supersonic and others.

.jpg;width=70;height=70;mode=crop)