UV-curing grows composites market share

Established and flourishing in the underground pipe relining arena, UV-curable resins are finding new applications in other out-of-the-way places.

Ultraviolet-curable resins were introduced in the 1960s. But their use in composites was eventually abandoned in favor of heat-curing materials because of the latter’s ability to form thick-walled parts, as well as their potential to adequately crosslink with either glass or carbon reinforcements. The part thickness achievable with early UV-curable resins, by contrast, was severely constrained by the distance UV light could penetrate the laminate in thick parts, particularly in a timely way, to stimulate cure, because it was absorbed as it passed through the progressive laminate layers. As a result, cure might be overdone on a surface (brittle) yet underdone deep within the part. And carbon fiber, being black (opaque), blocked the light, so it made UV impractical for carbon composites, and this still tends to be the case.

In 1986, however, BASF Corporation (Ludwigshaven, Germany) introduced a game-changing class of two photoinitiators — the molecules that, when exposed to UV light, form the reactive free radicals that initiate crosslinking in the polymer. “Of the two photoinitiators, bisacylphosphine oxide (BAPO) has become the workhorse for composites and laminates,” says Eugene Sitzmann, technical specialist, photoinitiators, BASF. In technical terms, UV-light-exposed BAPO undergoes a homolytic α-cleavage at the carbonyl-phosphorus bond to generate two free organic radicals. Both of the free radical species are capable of initiating polymerization, but each does so with a different rate constant. BAPO exhibits UV-near-visible absorption around 350-380 nm, extending up to 420-440 nm. The technology provides a host of advantages, most notably deep laminate through-cure once lacking in early systems and cure-on-demand rates as fast as 1-3 minutes.

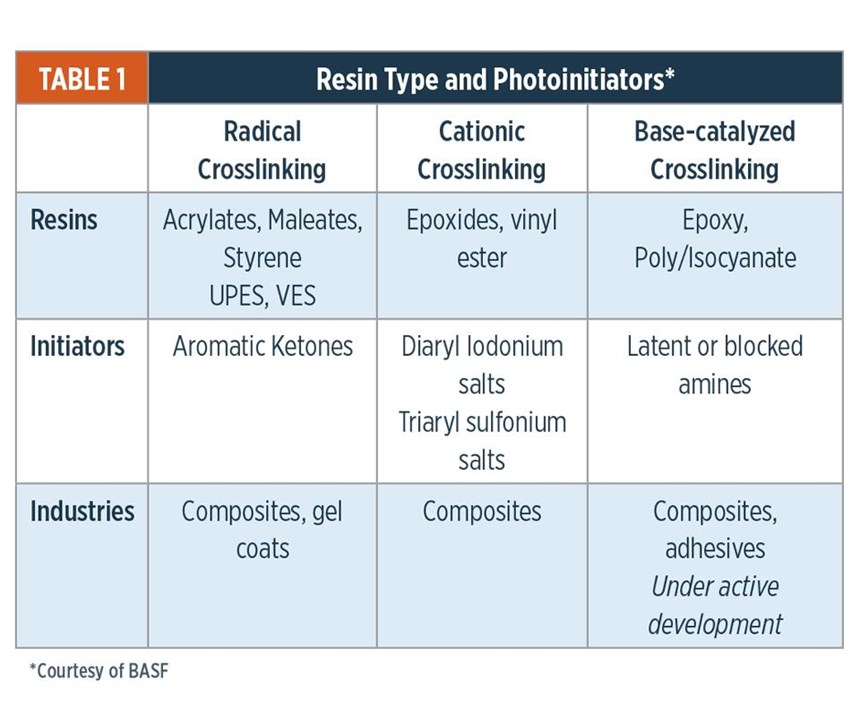

Today, these photoinitiators, and a variety of newer ones, are used in several applications, including cured-in-place pipe (CIPP), lament winding, pultrusion, preforming, as well as gel coats. Although the majority of UV-curing composite applications employ unsaturated polyester or vinyl ester resins, a variety of resin-photo-initiator systems have been developed, and development work continues (see Table 1, above).

CIPP a growing UV-cure market

Although heat-curing and UV-curing composites are both employed in CIPP applications, the latter is experiencing a significant upturn. With either, the basic principle is to repair a damaged or corroded pipe by placing a pipe liner within a pipe. Introduced in Europe in the 1980s, UV-curable resins for CIPP applications now own a large share of the market in that region, and a growing market share in North America.

Resin suppliers working in concert with pipe liner manufacturers have been able to optimize the initiator packages to successfully cure liners at thicknesses of 0.5 inch to as much as 0.75 inch (12.7-19 mm). Liners with thicker walls facilitate the repair of larger-diameter pipes with higher loading requirements, thereby enlarging the window of potential trenchless-pipe applications. As a result, “UV-curable liner manufacturing in the US has taken off in the past 5 to 10 years,” says Bill Moore, product leader, CIPP, at materials supplier AOC Resins (Collierville, TN, US).

Typically, these thick liners are manufactured as a resin-impregnated, glass fiber tube or sleeve, which, in its uncured state, is flexible and collapsible, allowing it to be efficiently packed and shipped to the installation site. First the liner is placed in the pipe. One technique to accomplish this — employed with all UV-cured liners — is to manufacture the liner with the curable side on the interior and pull the liner through the pipe.

One unique benefit to the use of UV-cured liners is that they can facilitate pipe/liner inspection before cure, improving the chances of a flaw-free installation: Once in place, the liner ends are sealed, the tube is inflated with air, and a camera attached to a light train is pulled through the pipe. On the way, the camera is used to conduct an inspection of the liner’s entire length. When the inspection is finished, the light train is pulled back through in the other direction, with a UV light activated for curing. In theory, a similar system could be used to inspect a heat-curable liner (sans UV light source), which is cured by flooding the tube with heated water, but the additional cost and extra step would be prohibitive. “With a heat-curing system, if a rock or other obstruction or defect is in the line, you wouldn’t see it until the liner is cured, which results in a hard indentation in the liner,” says Moore. Other advantages of UV-curable resins include lower release of styrene, shipment without refrigeration and longer shelf life.

In 2011, engineers with the Knoxville Utility Board (Knoxville, TN, US) chose to repair an 8-inch (203-mm), 50-year-old clay sewer pipe with a UV-curable technology supplied by Reline America Inc. (Avenue Saltville, VA, US). The fiberglass liners were impregnated with an unsaturated polyester, Vipel, supplied by AOC and formulated for the application by Reline. Reline’s material was selected, in part, because an inspection revealed that the pipe was actively leaking, which could create cool spots and compromise the cure of a heat-curable resin.

The first phase of the installation, carried out by Portland Utilities Construction Co. LLC (PUCC, Portland, TN), was a pilot project to line 2,991 ft/912m of pipe. It is worth noting that PUCC had not worked with UV-curable liners previously, but received all necessary certification, installation and technical support from Reline. After successful completion of the pilot phase, city engineers targeted an additional 6,533 ft/1,991m of pipe for repair for a total of 9,524 ft/2,903m of installed liner.

Mike Burkhard, executive director of business development and technological development, says Reline America has installed more than 2 million ft (609,600m) of liner since opening its doors in 2006. Although the largest market for CIPP is sanitary sewer, Burkhard reports strong growth in the storm sewer and potable water markets. The company’s trademarked Alphaliner UV-curable liners are manufactured via a patented, seamless spiral-winding process, which facilitates quick modification of liner construction, as well as liner shapes, which are not always circular, including elliptical, pipe-arch, etc.

In the liner-winding process, a variety of glass mat materials is processed through a resin bath. The impregnated glass mat is then fed into the spiral winder, which executes a number of synchronized processes to assemble the layers and materials going into the liner. Reline specifies boron-free ECR glass for the design of its glass mat, which incorporates several different weave patterns for different applications. Depending on the application, the liners are impregnated with either a UV-curing polyester or vinyl ester resin. The company formulates the final resin compound in-house; one of the key components is a proprietary thickening technology that produces resin with precise, and unique, viscosity values at different phases of the manufacturing process — wet-out, winding and curing after installation.

A typical liner construction comprises an inner clear plastic film over which the glass composite is spiral-wound. Above that is a proprietary layer of material that limits expansion during cure to between 8% and 12% and, finally, an outer, UV-resistant film to prevent premature cure during liner installation on site. The construction also includes two strands of glass roving, one along the top and the other along the tube’s bottom at installation, which absorb the pulling force as the liner is drawn through the existing pipe. After installation and cure, the clear film is removed from the liner.

Unique among North American CIPP liner manufacturers, Reline manufactures its own line of installation equipment. “It’s really hard to stay on the cutting edge in this business if you’re not manufacturing both equipment and liners in sync,” says Burkhard. He reports that the company typically supplies installers with a light train capable of generating 2,000W of power, and notes the company is currently developing a 4,000W system.

The equipment/material/process equation

One critical aspect to using or adopting UV-curing technology for composites manufacturing is the need to match the type, power and intensity of the light source to the application. Also important is an understanding of the best way to present the part to the UV light(s) in order to optimize the process.

Equipment supplier Heraeus Noblelight America LLC (Gaithersburg, MD, US) manufactures and sells a range of UV-curing light systems in hosts of applications. One of the most common is printing and coating processes. In the realm of composites, the company typically supplies lighting systems to fabricators or composite fabrication equipment suppliers, who, in turn, customize the lighting for each application.

Kevin Joesel, the company’s director of sales, Americas, says the most common type of UV source for composites manufacturing, thus far, has used medium-pressure mercury lamps. There are two general types of mercury lamps: Arc lamps, which are equipped with electrodes, and microwave-powered lamps, which are electrodeless. Both are broadband UV emitters; that is, they emit wavelengths across the entire UV-spectrum (200-400 nm), as well as in the visible and infrared (IR) regions.

The amount of radiation is a function of the surface area of the lamp. Microwave lamps, typically about half the diameter of most arc lamps, emit less UV and IR radiation. The IR load is a concern mainly in certain coatings applications in which heat buildup could be detrimental to the substrate. In both technologies, dichronic coatings are used on reflectors to absorb and reduce IR in IR-sensitive applications. In most composites applications, however, heat is good and improves the rate of reaction. In fact, dual thermal and photoinitiator packages have been developed for resins to speed cure. Such hybrid systems are ideal for thick-walled parts, and for parts with complex 3D shapes that might be difficult to expose to a light source without casting shadows, reports BASF’s Sitzmann.

In the UV-curing industry as a whole, however, the dominant trend is toward UV LED lighting. Although more expensive than lamps up front, LEDs offer several advantages. As semi-conductor devices, they are more energy efficient and have a much longer service life than arc lamps: Some companies claim useful life in excess of 20,000 hours, compared to a typical arc lamp life of 1,500 hours. LEDs also are monochromatic devices: they emit light within a narrow bandwidth at the UV spectrum’s upper range (380-400 nm), and thus eliminate concerns about heat buildup, as is common with conventional mercury lamps. But this, in turn, means longer wave-length-absorbing photoinitiators are required to facilitate curing.

Because LEDs are smaller and lighter than other UV-curing lamps, their primary composites application so far is for field repair of composite patch materials on various substrates. But they also are used commercially to cure gel coats. Joesel says, at present, there are no production-scale, UV LED composites applications of which he is aware. While technically feasible, adopting LEDs to cure composites would incur a high initial cost, creating a barrier that might be too high for most manufacturers: In addition to the price premium of LEDs themselves, using LEDs would require modifying the coating, photo-initiator and perhaps even the resin. In an existing application, it would also require a fabricator to requalify the process and the material.

One of the largest markets for UV-curing lamps, both industry-wide and for composites, is fiber-optics, Joesel reports. Individual, UV-coated, fiber-optic strands are packaged in bundles to create fiber-optic cables. The cables require a pultruded, glass-reinforced structural member packaged within the bundle, to relieve stress on the fibers. The part is cured as it exits the die; a light-curing system can comprise numerous, medium-pressure lamps, typically microwave, with a typical production rate of 600 inches/min (1,525 cm/min).

Microwave lamps also are usually the system of choice in UV-cured filament winding, a process that naturally lends itself to UV-curing because parts rotate on a mandrel and can be easily exposed to light, curing in a few seconds. Some parts made via UV filament winding include liquid propane and oxygen cylinders, piping and other tubular-shaped parts. UV curing can be applied to filament winding processes by several techniques, including B-stage curing, complete cure and gel-coat cure. In a B-stage cure, a UV lamp is placed just after the resin bath, but prior to winding onto the mandrel, which partially cures the resin into a tacky state on the roving. This partial cure, in turn, facilitates faster winding speeds — the resin is “stuck” to the mandrel. The laminate is completely cured by positioning one or more lamps in other locations near the mandrel. Other benefits include the ability to wind at high approach angles, more consistent part thickness because the resin is instantly cured on each lament, and less resin waste.

Although it has grown in recent years, the disadvantage of UV-curable lament winding is that it is primarily limited to glass-reinforced parts, because light energy cannot readily pass through the light-opaque fibers in a carbon fiber composite laminate. One technically “non-heat” method that has been used to cure carbon parts is an electron beam (EB) accelerator used in combination with cationic, diaryl iodonium photoinitiators. When activated by the EB source, these compounds generate a “super acid” that can crosslink epoxy and epoxy/polyols in opaque materials, such as carbon fiber. The process has been used to manufacture radomes and other aerospace parts and, according to BASF’s Sitzmann, typically requires thermal post-cure to achieve final desired properties, in terms of Barcol Hardness, modulus, etc.

UV at the front of new product developments

One critical benefit of UV-curable resins is that they are not simply enabling the replacement of slower, less environmentally sound conventional curing options in established applications (although they can be expected to continue to do just that), but that they are a low-cost enabling technology that is opening up new application space. This subtle principle is illustrated by a variety of new product applications.

Materials supplier and occasional composites fabricator Sunrez Corp. (El Cajon, CA, US), sells a line of UV-curable resins, prepregs and putties used in the aerospace, marine and other industries. Sunrez president Mark Livesay says the company originally purchased its light-curing resins from BASF, but has been manufacturing its own products for nearly 20 years. He says the materials, which include polyester, vinyl ester and urethane formulations, have continually been modified and refined for various applications, providing manufacturers with the capability to mold fully cured parts up to 0.5 inch/12.7 mm thick, in less than 5 minutes, with glass fiber loadings as high as 70%. Livesay points out that UV curing has the advantage of being temperature agnostic: Cure is effective even in extremes of heat or cold (-40°C to 49°C), which makes the materials suitable for deployment in military operations or in remote, inhospitable conditions.

One of the company’s first products was surfboard repair kits, consisting of a UV-curable prepreg and a UV-curable putty Sunrez developed in-house. That business, in turn, morphed into fiberglass repair patch kits for military armored vehicles. During Operation Desert Storm in Iraq, Sunrez supplied the US Army with thousands of patch kits for the Bradley Fighting Vehicle’s turret. The repair patch featured a prepreg comprising a double layer of 24-oz woven roving, and 1.25-oz glass mat impregnated with vinyl ester, which matched the Bradley’s turret design. The resin used in the application has an ambient temperature shelf life of one year, according to Livesay. The prepreg can be cured using a handheld UV lamp, or by ambient sunlight. The putty, with a shelf life of more than five years, was used to fill in any irregular surfaces around the patch edges.

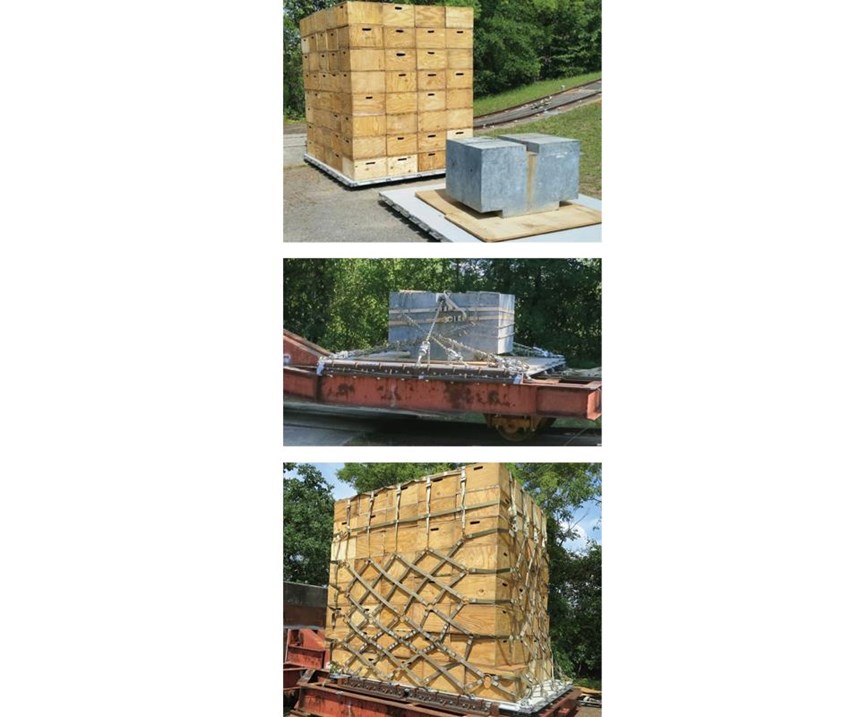

At present, Sunrez is participating in a project overseen by the US Air Force to qualify its materials for the redesign of its 463L pallet. First designed in the 1950s, the 463L (also known as the HCU-6/E) is the primary, uniform-sized cargo pallet used in the C-130, C-5, KC-10 and other military transport aircraft. It measures 88 inches by 108 inches by 2.25 inches thick (2.24m by 2.74m by 557.15 mm) and is constructed of planking (a balsa wood core between aluminum skins set within an aluminum frame, equipped with tie down rings). There are an estimated 163,000 pallets in the Air Force’s transport system. The pallet’s design, unchanged since the mid-1960s, has proved serviceable, but with aging, the skins are subject to breaks, cracks and water intrusion, which causes the balsa to swell and grow mold. The Air Force wants to redesign the pallet with more durable and, ideally, lighter materials.

Sunrez’s candidate for the program is an advanced, recyclable pallet with composite skins consisting of high-strength glass impregnated with UV-curable resin surrounding a proprietary, new-generation UV-curable (non-urethane) foam core. The latter reportedly provides compressive strength equal to or better than balsa, says Livesay. The skins for the test phase of the project were made by infusing six plies (for the bottom skin) and five plies (for the top skin) of 19-oz., 0°/90° glass fabric. Complete cure is accomplished in only 58 seconds, with a glass content of ~65%.

Livesay reported at CW press time that testing was about 60% complete, with environmental/weathering tests ongoing, toward a next-phase requirement of 2,000 pallets for field testing. “The project is evaluating the designs of several suppliers, but so far, we are looking darn good,” he says.

Assuming the new design is selected, the Air Force is expected to request procurement of about 56,000 pallets per year for 3-4 years. If awarded the contract, Livesay says Sunrez will partner with a fabricator to specify a new sheet line for the skins, as well as a production line for the cores.

UV curing for repair of wind turbine blades

UV-curable composites’ temperature-insensitivity and utility in remote operations is attracting attention in the wind energy market, especially for field repairs on turbine blade leading edges, which receive the brunt of cumulative erosion from rain, ice, airborne particles, bird strikes and, occasionally, lightning strike.

Introduced in 2010 and targeted toward structural repairs of wind turbine blades, Gurit UK’s (Newport, Isle of Wight, UK) RENUVO UV-curing prepreg can be used in temperatures as low as 5°C. Available in unidirectional and biaxial formats with as many as three plies of 600g/m2 E-glass, the prepreg is used in combination with the company’s Multi-Purpose System (MPS) and can be cured in 3 minutes, for leading-edge repair without the need for secondary operations to fill and fair.

Wind turbine blade service company Rotos 360 (Kings Lynn, Norfolk, UK) has been using the product to conduct turbine blade repairs in the North Sea. Repairs on leading edges are logistically and physically daunting operations, typically performed from suspended-access platforms deployed from the deck of a service vessel. Workers grind out gel coat cracks, fill with MPS paste and cure it in seconds. Larger damage is first ground out, and the size of the required prepreg patch is radioed to the service vessel. The patches are cut to size, pre-consolidated, using heat and vacuum, and delivered to the repair crew. The patch is applied to the blade and cured in a few minutes using a handheld 8-W/cm2 LED UV solid-state lamp. The UV-curable repair system is a dramatic improvement over the two-part conventional patch systems previously employed, which could take hours to cure.

UV-curable composites having high impact on health care

The flexibility and user-friendly aspects of UV-curable composites are amply demonstrated by a recent medical application that aims to bring a new custom orthotics solution to market. The technology is being developed and licensed through Light Orthotics (Westlake Village, CA, US), a company founded two years ago by Alan Jacobsen. Jacobsen, a composites engineer by training, had previously worked 12 years at a large, private-sector research lab, developing a new micro-lattice, composite-core technology based on UV-curable resins, before he left to found his startup. The product is currently undergoing tests, on a limited-release basis, by health professionals and patients in the greater Los Angeles area. The orthotic comes packaged as a flat, precured, foot-shaped Prethotic, which consists of two, distinct multiaxial, E-glass laminate layers impregnated with an acrylate-based resin formulated in-house. The total thickness of the laminate layers is approximately 2 mm. The glass is supplied by SAERTEX USA LLC (Huntersville, NC, US) and is impregnated via conventional wet layup. The Prethotic is packaged inside a clear plastic bag, which, in turn, is packaged in a UV-blocking plastic liner.

A “light box” equipped with UV LEDs at the doctor’s office is used to cure the Prethotic. A thin film is pulled over the box and the Prethotic is removed from the outer, UV-blocking package. The Prethotic is placed on the film and the doctor or therapist presses the patient’s foot down and forms the Prethotic around the foot (see photo in montage, above). When the foot is in place and fully formed to the Prethotic, the light is turned on, curing the resin and creating a custom-fitted, composite orthotic. The orthotic is fully cured in ~2 minutes. When the laminate layers are cured, the clear plastic packaging is removed. The UV process saves time compared to legacy custom orthotics, which require sending a cast or digital image of the foot to a lab. The UV technology also produces an orthotic that is lighter and thinner than most other orthotics, says Jacobsen.

UV-curing technology is a best fit for high-value and high-volume applications, Joesel believes. As such, adopting UV in more conventional industrial composites applications, using open molding and RTM processes, can be challenging. Joesel reports, for example, that a number of years ago, an automotive supplier used a UV-curable surface primer on SMC panels because it helped prevent paint pops and surface defects. But the process was eventually mothballed, primarily because of costs associated with the materials, which could not be recouped in volume production. That said, today, the changing dynamics in the automotive and aerospace markets — especially the greater demand for lightweight materials, such as composites — is and will undoubtedly create fresh opportunities for the inherent benefits provided by UV-curing technology.

Related Content

National Composites announces partners with compression toolmaker Laval

The new alliance will broaden National Composites’ capabilities in SMC and BMC and tooling, while providing customers with comprehensive solutions, from initial design to final delivery.

Read MoreDucati introduces lightweight motorcycle seat support rear frame

Forged molding compound (FMC) material from Mitsubishi Chemical and Gemini Composites replaces aluminum part on Ducati Hypermotard 939, reduces part weight by 40%.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreSMC BMC Design Award 2022 winners are revealed

Gold and Silver awards include SMC LightTurn design for seated showering, an SMC floating platforms for sustainable, floating gardens and a BMC TileTurn Solar reflective sustainable roofing solution.

Read MoreRead Next

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read More