The building envelope: Betting on the big time

Building code changes and growing architect familiarity feed more frequent composites use in large-scale commercial construction.

In the past decade, composite materials have ticked all the right boxes in many high-performance, high-profile applications. Notable examples include aircraft airframes, critical corrosion-resistant structures at industrial chemical plants and, most recently, the automotive industry’s recognition of composites’ potentially great utility in the chassis and body in white. But in the still-developing building and construction segment, progress has been slow. Efforts by the American Composites Manufacturers Assn. (ACMA, Arlington, Va.) to modify the International Building Code (IBC) and a growing awareness of composites’ environmental sustainability through lifecycle analysis tools have, thus far, earned the composites industry small gains into what architects call the building envelope. Exterior decorative elements, such as cornices and columns and, more recently, window lineals, entry doors, skylights and light panels represent a beginning. But Bob Moffit, product manager at Ashland, LLC (Columbus, Ohio) and the head of Ashland’s building and construction resins arena, speaks for many industry observers when he says, “There are still tremendous opportunities for composites in structural wall panels, foundations, building cladding and roofing.” Indeed, the architectural community is — at last — taking notice of composites’ performance and cost advantages in large-scale projects, which translate to overall lower costs. Now it could be time to get pencils ready for another big check mark — composites are gaining momentum in high-profile commercial and residential building applications.

Meeting code and bringing benefits

Composites bring to architecture the same benefits that other sectors have already exploited. At 20 percent of the weight of stone or concrete cladding, a composite exterior can significantly reduce building dead load, which translates to a smaller foundation, a more manageable seismic design and smaller crane requirements. This results in material and cost savings that cascade through the entire project. Further, composites’ durability and weather resistance mean less maintenance and cleaning cost over time, an issue that is especially important for city-owned buildings, which often have to undergo cleaning. As candidate materials, composites also offer design flexibility that feeds an architect’s creativity — unusual forms that are not feasible with traditional materials often can be readily fabricated. Perhaps most important — and in this, Moffit is supported by Bill Kreysler, president of Kreysler & Associates Inc. (American Canyon, Calif.), a well-known composites champion for architectural applications and the head of ACMA’s Architectural Division — lifecycle analyses have shown that composites are actually more environmentally sustainable than concrete, aluminum and other conventional building materials (see “Life Cycle Assssment: Are composites 'green?" under "Editor's Picks," at top right”). Cost, as always, can be an issue. Although fiber-reinforced polymer (FRP) panels are similar in price to glass fiber reinforced concrete (GFRC) panels, for example, they are more costly than other common building materials. But when composites bring unique advantages to architects, the additional cost can be justified. In addition, composites have made headway into building codes, which is a huge step forward, says Kreysler. “Architects now understand better where they can use composite materials,” he explains. “If there is ever a problem, the designer or architect can say, ‘I made the decision to use this material, in the way that the code says is acceptable.’ It makes the entire architectural community more comfortable.”

For architects and builders in the U.S., the IBC, published by the International Code Council (ICC, Washington, D.C.), prescribes when and how products may be used. Europeans rely on Eurocode or a country-specific code. In the Middle East and Asia, codes tend to be a mix of U.S. and British standards. In 2009 the ICC voted to allow the use of composite materials for both interior and exterior wall applications, as reflected in the code’s latest edition: IBC Chapter 26, “Plastic,” and Subsection 12, “Fiber-Reinforced Polymer.”

In essence, the IBC says that FRP can be used on the exterior walls of a building of any type of construction, provided the materials are noncombustible or meet certain requirements laid out in Section 2612.5. This includes curtain wall panels and rainscreen panels, a subset of curtain wall designs that feature a thin exterior panel over a ventilated cavity that allows equalization of interior and exterior air pressure to prevent water infiltration. Section 2612.5 requires the composite material to meet the acceptance criteria of NFPA 285, the National Fire Protection Assn.’s (NFPA, Quincy, Mass.) rigorous performance-based fire test, and earn an equivalent IBC Class A rating, measured by the ASTM E84 test with a flame spread index (FSI) less than 25 and a smoke-developed index (SDI) less than 450 (where asbestos/cement board’s FSI = 0 and red oak’s FSI = 100). According to Nick Dembsey, fire protection engineer and professor at Worcester Polytechnic Institute (WPI, Worcester, Mass.) and the head of ACMA’s Fire Committee, composites can and do achieve these standards. “It’s definitely possible to pass these tests, and it’s been done in the U.S. and in Canada. Depending on the type of exterior panel application, additives in polyester resins, phenolic resins, and a glass fiber content greater than 40 percent all contribute to successful product compliance. The use of veils or coatings to harden the surface is also an approach. Fabricators can get into the game by fine-tuning current technology.”

The architectural community is catching on. Moffit, who oversaw an exhibit at the recent Greenbuild International Conference and Expo in San Francisco, Calif., sponsored by the U.S. Green Building Council, notes that there was considerable interest in a code-compliant composite wall panel fabricated by Kreysler’s firm: “The advantage of the low weight and high strength was easy to understand, and they understand the obvious value of the reduced structural demands compared to alternative cladding materials. They were excited about the design flexibility, at low incremental cost, that composite panels could offer.” Cornelius (“Kin”) DuBois, an architect and a fellow with the American Institute of Architects (AIA, Washington, D.C.), admits, “Architects are always intrigued by new materials. If they can perform and meet code, and provide some unusual capability, then it’s worthwhile, despite added cost.” He points out, for example, that a lightweight, insulated curtain wall system that could be produced in large sizes, reusing molds to minimize fabrication cost, would be attractive and would require fewer “picks” with a crane, expediting installation. Thomas Fagernes, a director and partner in the high-profile architectural firm Snøhetta A/S (Oslo, Norway, and New York, N.Y.), says, “Used wisely, depending on the project geometry and circumstances, composites definitely have a role, despite their generally higher cost, and allow architects to execute complex geometries.”

Mainstream rainscreen panels

Some manufacturers of composite products are already well entrenched in the exterior cladding market, particularly the flat panels used in rainscreen applications. Perhaps the best known is 50-year old Trespa International BV (Weert, The Netherlands), the producer of a flat, compact composite high-pressure laminate (HPL) panel product trademarked Meteon. Used as a decorative exterior panel in ventilated rainscreen systems and typically supported on an aluminum frame, Meteon contains roughly 70 percent cellulose kraft paper in a phenolic resin matrix. Panels are pressed at high temperature and pressure and are cured using a proprietary electron-beam process. The result is a highly durable panel with good UV resistance and an integral surface finish, available in multiple colors and textures, says Todd Kimmel, senior façade application specialist for Trespa North America, a wholly owned subsidiary of Trespa International.

On the market for more than two decades, Meteon has been incorporated into hundreds of commercial and residential exteriors worldwide. A recent Meteon project involved a large-scale condominium complex overlooking Rostock Harbor in northern Germany, the site of a historic shipyard. Architect Martin Beyer of Beyer Architeckten (Rostock, Germany) chose Meteon over traditional brick or white “render” (a plaster-like coating that can be painted or overlaid with stucco) and selected rusty-iron and weathered-copper finishes that capture the ambience of the old shipbuilding site. “We value Trespa Meteon as a durable, UV-resistant and color-fast material,” says Beyer. “Furthermore, it is not susceptible to coastal weather conditions, with salty air and constant wind. Trespa will remain a part of that process for the design freedom it offers us.”

The company recently conducted an internal study of panel durability by sampling exterior panels from three 1980s-era projects and testing them alongside new panels. Panels on the District Police Station in Rotterdam, The Netherlands, designed and built in 1988, had barely faded or changed. According to the company, the façade was exposed to considerable exhaust fumes and general pollution, as well as normal weathering. The study shows that after 20 years, the building’s original Meteon panels and the brand new Meteon panels were, in terms of color and general condition, a “perfect match.”

A relatively new player in the panel market, Acell (Milan, Italy), has produced fire-resistant phenolic structural foam for construction and transportation applications for 25 years. The company introduced an award-winning molded panel concept several years ago, in partnership with Italpresse USA Inc. (Bagnatica, Italy, and Punta Gorda, Fla.) and Ashland (see “Cladding controversy .... " and "SMC Sandwich panels ...." articles under "Editor's Picks”). Using a low-pressure press, Acell foam is combined with glass-reinforced sheet molding compound (SMC) outer skins to form planar panels that can mimic architectural textures and details with ease, with low-cost cast molds and decorative veils and pigmented powder in-mold coatings (PiMC). The technology has already been adopted for doors, and Acell is aiming for the façade panel market as well. Brickwork, marble and other stone, wood grain and more can be replicated, in any color.

Acell was recently tapped for a new low-cost student housing project in Étaples-sur-Mer, in northern France, designed by Philippe Castelain; Acell’s customer is Essor Promotion (Paris, France). The three-floor building contains 120 apartments and, according to Acell’s managing director Michael Frieh, will be faced with 5,000m2/54,000 ft2 of Acell’s prefinished, insulated exterior panels installed within a metallic support structure. In this case, the builder also will use prefinished Acell panels for the interior walls. Decorative veils will eliminate the need for painting and facilitate rapid construction, enabling project completion by September 2013. The exterior Acell panels not only meet the required fire standards and provide the necessary thermal and acoustic insulation properties, but they also add wind resistance (up to 186 kmh/115 mph).

“The panels give the architect the ability to create a very nice contemporary finish at no extra cost,” says Frieh. “Plus, the modular aspect of the construction means installation in record time.”

The company recently introduced its Compass House concept (pat. pend.), a unique design developed by students at the Polytechnic University of Milan (Politecnico di Milano) and architectural firm Studio Marco Albini (Milan, Italy). Intended to provide a very quick building solution with modern amenities, Compass House is factory-built and delivered to the job site as modular flat packs, which can be assembled as individual units or joined together to create larger units, explains Frieh. “One of the main characteristics of the Compass House is its flexibility. In fact, from one standard ‘Compass’ shape, many different configurations can ... provide a solution for small housing units as well as very luxurious contemporary single villas.” The concept uses the Acell IN & OUT composite wall panel, a single panel, which has an external finish backed with an internal glass-reinforced gypsum (GRG) surface that is ready to paint, wallpaper or tile.

Panels with curves

Beyond the previously described fast-cycle, commoditized flat panels are custom composite curtain wall façade panels that include insulation, windows and, often, fastening systems that connect them to the building’s floor slabs or other internal support structure. They keep the weather out but are not structural. That is, they must be strong enough to support their own weight in addition to wind loads, but they do not carry additional loads. When they are fabricated in composites, such panels can be molded in complex shapes to satisfy an architect’s unique vision. “Designers are getting away from ‘flat,’ today,” says Kreysler. “It’s now possible to produce via CAD the entire design for a building, including the electrical, insulation … everything. Those data files can be transferred seamlessly to cutting tools to create the tooling for exterior panels.” Kreysler’s firm used the technology recently to create a fire code-compliant exterior curtain wall panel demonstrator in a bid to win an exterior facade project in San Francisco, Calif. (see photo, p. 19). Although details of the materials used in the panel to pass the NFPA 285 test were withheld, Kreysler says the technology is similar to that used to produce acoustic panels for the Bing Concert Hall in Stanford, Calif. (see “Concert hall composites: Acoustic alchemy," under "Editor's Picks”). To keep costs down, the panel is designed to be replicated using a limited number of tools.

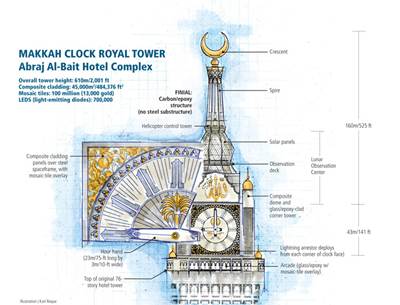

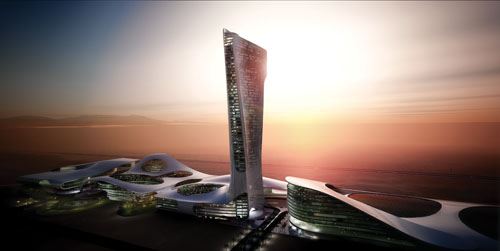

Gabi Bohm, an architect and composites specialist at Premier Composite Technologies (PCT, Dubai, U.A.E.), well-known for its massive architectural elements (see “Besting Big Ben: A Marvel in Makkah,” under "Editor's Picks"), says, “We receive a tremendous number of inquiries from architects all over the world regarding curtain wall cladding systems. They understand the advantages of prefabricated, lightweight components that can be installed in modular fashion.” She describes a recent example of a modular panel concept for the hotel tower within the RAK Gateway project, located in Ras Al Khaimah, a new emirate city 150 km/90 miles east of Dubai. The tower — if completed (the RAK Gateway project is currently on hold) — will rise above a huge complex that will include an exhibition center, more hotels and conference space. Designed by Fagernes of Snøhetta, the striking 200m/650-ft tall curved tower, faced with ceramic tiles, required a unique solution (see photos). Composites ultimately were chosen over glass-reinforced concrete (GRC) and metal, says Bohm.

Fagernes envisioned a fully structurally clad envelope for the tower, delivered to the site as ready-to-install modules, which could be attached to the building slabs without further substructures. This approach will require that each exterior panel be fully insulated, incorporate external structural skin, surface finish and all door and window components as well as the fixing grid for interior fit-out. That challenge was met by PCT after months of trials, including tests of a variety of proprietary materials and different panel sizes. Ultimately, PCT built a prototype panel that measured 4m by 8m (13 ft by 26 ft), one of approximately 1,000 panels required to encase the entire building. According to Bohm, each panel has a complex biaxial curved shape and is made from a sandwich of glass fiber/epoxy skins. Structural bonded glass windows were built into the panel, which was decorated with contemporary ceramic tile in a repetitive geometric pattern.

If the tower is constructed the prefabricated panels will be hoisted by crane and attached to one another with a watertight, bolted panel-to-panel connection, significantly reducing the cost and time necessary to mount the facade. Adds Fagernes, “I have had a wonderful experience with PCT with this facade concept. I am impressed by how complete, large panels that are very lightweight can be fabricated — it makes construction much more precise.” Fagernes’ firm is applying the composite facade panel approach to the new and unusually named Barcode office building in downtown Oslo, Norway. Completion is expected in 2013.

PCT also is moving ahead with an innovative composite roofing panel design for one of three huge rail terminal buildings, part of the Haramain High Speed Rail project. Currently under construction in Saudi Arabia, the 444-km/276-mile high-speed intercity transport system will link the major Saudi cities of Madinah, Makkah and Jeddah. PCT will manufacture the panels for a consortium that comprises Istanbul, Turkey-based Yapi Merkezi Construction and the Jeddah-based Saudi Binladen Group (SBG), the construction lead for the Madinah and Makkah stations.

The structural roofing panels will be prefabricated sandwich constructions, with a lightweight core between glass fiber/epoxy faceskins. Clear, diamond-shaped windows will allow natural light to enter the station (see photo). PCT was awarded the job following successful work on a prototype, with project architects Foster + Partners (London, U.K.). The prototype showed that the complex design could be easily realized with composites and that it could meet all fire and safety requirements. In addition, the lightweight panels should facilitate construction because they can be easily lifted into place during installation. The roof surface for the stations will require 2,048 panels, with a total surface area of 26,000m2 (280,000 ft2). Production is underway.

Increasing awareness

What is the next step? Architect DuBois says the composites industry needs to increase awareness and familiarity with composite products, which could include a presence at architectural gatherings, such as the AIA’s national convention. Fagernes says his positive experiences with composites has him excited to see how the industry develops, but he “would like to see less expensive, and more available, fabrication and distribution methods.”

Concludes Moffit, “The conversion from traditional materials to composites in any one of these building envelope applications would dwarf the current use of composites in construction.”

Related Content

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MoreMaterials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreRead Next

“Composites and Architecture” blog

In an effort to publicize architectural composites, Kreysler and Associates Inc. (American Canyon, Calif.) has begun a blog, called “Composites and Architecture” (www.compositesandarchitecture.com).

Read MoreBesting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

Read MoreCladding controversy: SMC insulation panels preserve pre-1919 building aesthetics

Acell (Milan, Italy) offers a solution for insulating older buildings that is designed to satisfy advocates of both architectural preservation and environmental conservation.

Read More

.jpg;maxWidth=300;quality=90)