RTP Niches Into Low-Pressure Applications

Wellstream (a Halliburton business unit) supplies lightweight reinforced thermoplastic pipe, or RTP, which is designed for applications intermediate between those that can use low-pressure, unreinforced thermoplastic pipe or hose, and those that require high-pressure unbonded flexible pipe. Used mainly in onsh

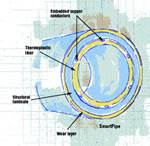

Wellstream (a Halliburton business unit) supplies lightweight reinforced thermoplastic pipe, or RTP, which is designed for applications intermediate between those that can use low-pressure, unreinforced thermoplastic pipe or hose, and those that require high-pressure unbonded flexible pipe. Used mainly in onshore flow line applications where the life cycle cost is less than steel pipe, RTP is available in sizes ranging from 3 inches/75 mm up to 10 inches/260 mm (ID). RTP features a polyethylene liner, a helically wrapped aramid fiber armor layer and an exterior ultraviolet-resistant thermoplastic barrier, and it offers service pressure as high as to 2,200 psi/150 bar.

Offshore applications likely will be shallow water installations where high collapse resistance is not needed. Here, RTP is more cost effective than steel pipe on a life-cycle or installed cost basis. Furthermore, RTP’s manufacturing process is straightforward and, therefore, offers the potential for near- or even onsite production with a modular manufacturing system. A joint industry project group — supported by BP, Coflexip Stena Offshore, Petrobras, Halliburton Subsea and Pipelife, among others — is currently developing guidelines for qualification and system design and has studied damage tolerance and repair issues. A draft ISO standard for RTP is in preparation (see Sidebar).

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.