Nanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

From its beginnings in 2004, the Nanocomp Technologies (NTI) story has been distinguished by tenacious, step-by-step progress toward faster, less cost-intensive production and commercialization of macro-scale carbon nanotube (CNT)-based advanced materials. Unlike previously available CNTs, which were powder-like and tended to agglomerate when added to resins, NTI’s CNTs are 1-10 mm long but only 3-5 nm in diameter. This remarkably high aspect ratio provides not only good tensile properties, but, exceedingly long compared to their thickness, the CNTs easily entangle. This fact enables NTI to collect them out of its chemical vapor deposition (CVD) furnaces and then convert them, inline, into either continuous fibers or 1.2m by 2.5m nonwoven sheets, offering a more amenable format for composites manufacturers (read more online by clicking on "Aerocomposites: The move to multifunctionality" under “Editor’s Picks” on the top right, and looking under the heading "Multifunctional macro-scale CNT fibers").

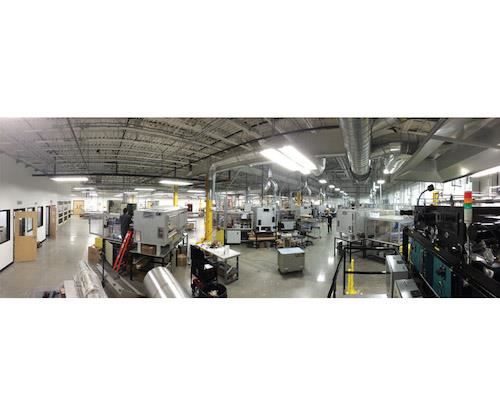

The macro CNT fiber can be continuously manufactured at the rate of kilometers per day, using inexpensive, readily available inputs, yet reportedly yields properties that produce measurable benefits in end-use components. NTI currently has a capacity of 0.85 MT per year, having scaled up from two furnace-enabled production lines in 2006 — one for continuous MIRALON CNT fiber and one for MIRALON nonwoven sheet — to 13 production lines, six for fiber and seven for sheets, today. Sheet stock then can be slit into tapes, cut into tailored sizes or seamed together to make roll stock. Along the way, the company has grown from a 50m2 facility in Lebanon, NH to Phase II of its repurposing plan for its current home base, the old 9,300m2 Nashua paper mill in Merrimack, NH, less than an hour’s drive from the techno-hub of Boston, MA.

CW’s guide to MIRALON products and production is NTI president Peter Antoinette. He says that roll stock made from MIRALON sheet can be spooled for processing into prepreg, which has already been demonstrated by Solvay Engineered Materials (Anaheim, CA, US). It also can be used to make honeycomb core. MIRALON fiber, meanwhile, has been used on its own in cables, impregnated with resin in composites and also processed into a dispersed format for 3D printing filament, with a variety of polymers, as well as chopped/compounded for use in compression and injection molding processes.

Although Antoinette touts an almost endless list of unique properties and potential applications for NTI’s CNT products, they have actually amassed more than five years of service in spacecraft and are being qualified at several aerospace OEMs. In fact, MIRALON is now classed by the US Department of Defense as “essential for national defense,” per the Defense Production Act (DPA) Title III program. Further, NTI has forged partnerships with industrial giants, such as DuPont (Wilmington, DE, US), and has secured commercial sales into data cables and ballistics protection/armor. The latter is key if NTI is to make good on its promise of a next-generation carbon fiber and composites that will deliver the improvement in weight savings, mechanical performance and multifunctionality now in demand for future structures.

Manufacturing macro CNT fiber

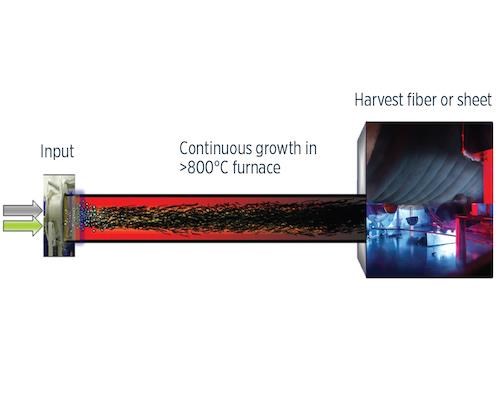

CW’s tour of NTI’s Merrimack facility begins in the building’s 2,800m2 Phase I pilot-production area (Fig. 1, below). Most of NTI’s 75 employees work here or in adjacent R&D labs. The area houses the furnaces and fiber/sheet production lines. Hydrogen (the company produces its own supply on site in an innovative, compact operation) and other common gases, mixed with industrial fuels and a catalyst, are injected into each furnace. As the mixture moves through the furnace, it is heated to more than 800°C to create a cloud comprising billions of CNTs — what Antoinette calls a “CNT sock” (Fig. 2, at left).

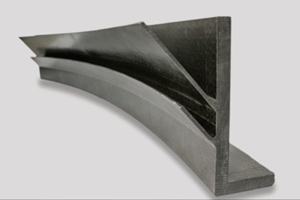

At this point, what happens to the sock differs, depending on the end product. At the output end of each sheet furnace, a harvest box winds the cloud of entangled CNTs around a gathering drum. The CNT sock then collapses into a felt, which is then heated to flash off the solvent, densifying the sheet (Fig. 3, at left). The sheet before densification resembles a very thin, friable carbon felt. Afterward, it is shiny and looks, perhaps not unexpectedly, like the carbon paper used decades ago to produce copies, sandwiched between sheets of typing paper.

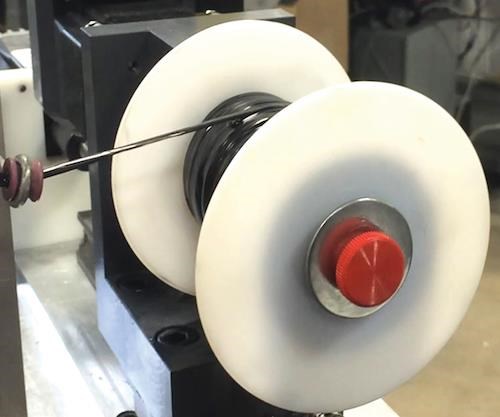

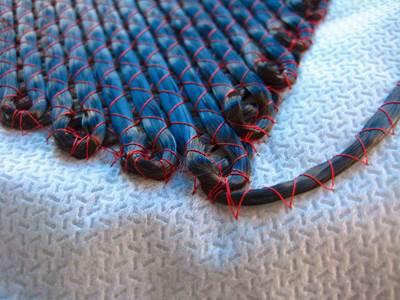

“Alternatively,” explains Antoinette, “we can collect the CNTs into a spinneret to form a yarn (Figs. 4 & 5,). We spin 10-tex filaments and further process to create a 4-ply twisted yarn with a breaking strength of 1.5 N/tex, similar to a 40-tex aramid fiber.” (KEVLAR 49 aramid fiber for composites is typically sold as 1,270 decitex, which is a metric unit for fiber linear density; dtex = g/10,000m while tex = g/1,000m).

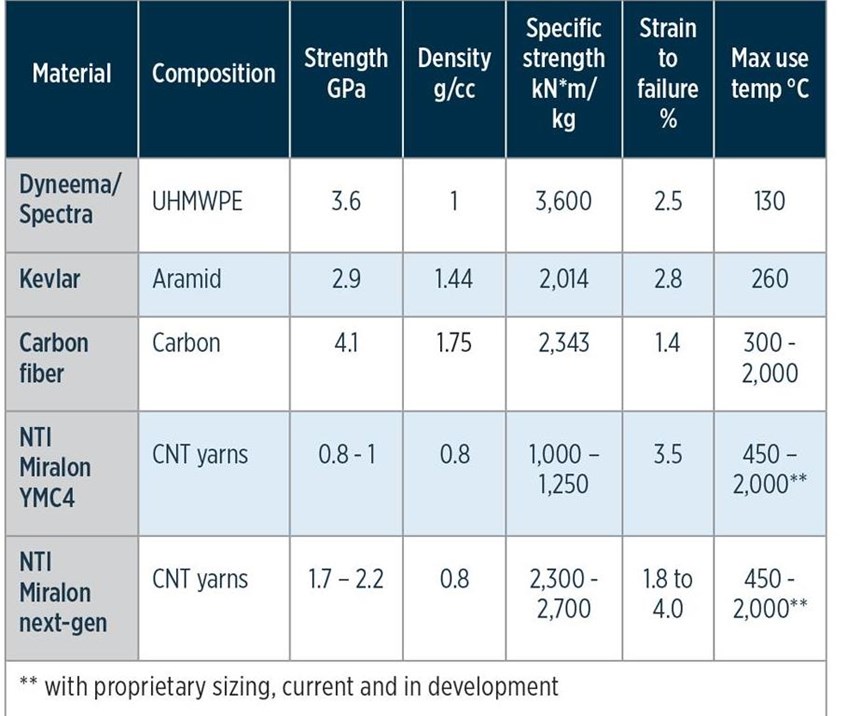

According to NTI tests (Table 1), MIRALON CNT fiber has a tensile strength approaching commercial aramid fibers but at a density that is roughly half that of carbon fiber (CF); thus, its specific tensile strength has the potential to exceed commercial CF products. It also has high knot strength, which means its tensile strength after being tied in a knot is very similar to its unknotted strength. Carbon fiber, by comparison, loses 99% of its strength when knotted, because carbon fiber is made from solid filaments. MIRALON CNT fiber, however, being formed by millions of entangled millimeters-long nanotubes, is essentially the nanoscale equivalent of a stretch-broken carbon fiber — carbon tows pulled to create a pattern of broken filaments, maintaining alignment but enabling movement, and thus increased flexibility (see Learn More). This CNT fiber is, thus, very flexible and easily used as a stitch yarn, for example, or in processes like tailored fiber placement (TFP, read more in "Tailored Fiber Placement: Besting metal in volume production" under "Editor's Picks"). It also has a very high surface area, available for bonding to resin and/or for conveying heat or electrical current.

Antoinette says MIRALON’s combination of properties is what makes it revolutionary: “You can ground it like stainless steel but also tie it into a knot. It retains properties at cryogenic temperatures and has the same environmental toughness as carbon fiber, but much greater thermal and electrical conductivity.” The latter also can be tailored, from parts that function as electrostatic discharge (ESD) and electromagnetic interfeence (EMI) shielding to data cables and wiring that meet the conductivity and data transfer specifications of current products but at only 30% of the weight. Data and communications cables for satellites were one of the first applications of MIRALON.

On a commercial jetliner, which requires approximately 98 km of wiring, Antoinette contends that use of MIRALON products could reduce weight by 2,540 kg.

Just beyond the production area, MIRALON sheet is unrolled on large tables in preparation for cutting into square panels for a ballistic armor customer (Fig. 6). The soft armor, used by police and paramilitary units, includes only a couple of layers of the sheet, but that’s enough to reduce backface deformation — the potentially injury-causing displacement into the wearer — by up to 20%, translating into a 25% lighter finished vest. Antoinette says this means a 2.7-kg vest would drop to 1.8 kg and be 30% thinner for improved comfort and maneuverability, yet maintain Level II ballistic protection. He notes this same ballistic performance is extended to composites applications, like tactical plates and helmets, working with partners such as TenCate Advanced Armor USA (Newark, OH, US).

The final stop on the production floor is, in fact, an example of NTI’s continuous push to increase production. A generation “D” fiber furnace is being tested, which will double line speeds to 12 m/ min. “We plan to roll these machines into production by the end of 2016,” says Antoinette, “but I’d like to see us improve production speed by another ‘5x.’”

Composites R&D

Antoinette leads the way past an array of quality assurance testing equipment to the next stop, NTI’s R&D lab. Here, principal scientist Joe Johnson notes that MIRALON has performance superior to that of carbon fiber in molded polyetheretherketone (PEEK) parts. “Compression molded MIRALON/PEEK does not exhibit the fractures seen in chopped carbon fiber/ PEEK parts,” he explains. “Meanwhile, we can maintain the near-zero coefficient of thermal expansion, and the parts exceed metal performance as well.”

NTI uses MIRALON sheets, cut and mixed with polymers, in both compression and injection molded composites, and has ongoing development projects with HyComp (Cleveland, OH, US) and other well-known compounders and industrial partners that can’t be named due to nondisclosure agreements.

This work, alone, reportedly holds enormous promise: Technical and market research results extol the opportunities for electrically conductive injection molding compounds, given the continued miniaturization and functionalization of electronics and electrical components.

Johnson’s team also shows CW how chopped MIRALON dispersed products are compounded into acrylonitrile butadiene styrene (ABS) plastic and then used in a commercial Fortus 3D printer (Stratasys Inc., Eden Prairie, MN, US) to produce avionics housings and structural brackets and adaptors for spacecraft (Fig. 7). NTI is completing development work with the University of Dayton Research Institute (UDRI, Dayton, OH, US) and Orbital ATK (Dulles, VA, US) toward full qualification of this material — as well as CNT-reinforced polyetherimide (PEI, e.g., Ultem), high-density polyethylene (HDPE) and nylon, for a variety of aerospace applications.

Service history in spacecraft

Spacecraft manufacturers, in fact, were early adopters of this macro-CNT technology. In 2011, raw MIRALON yarns were exposed in space for more than two years, as part of the International Space Station MISSE 8 ORMAT E-111 mission. Afterward, they were found in pristine condition except for a very thin oxide layer, similar to that formed on aluminum under similar conditions, proving they can function in the radiation, cold and corrosive atomic oxygen present in low Earth orbit.

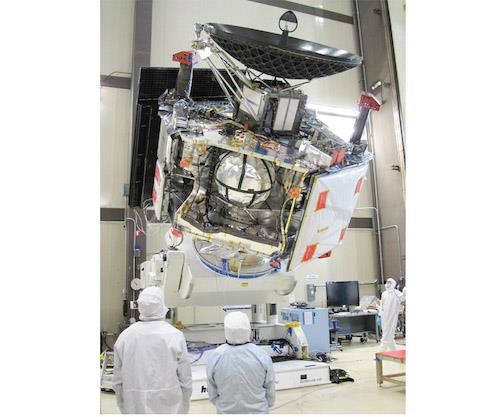

Also launched in 2011, the Juno space- craft, which reached Jupiter in July 2016, uses MIRALON sheet combined with M55J carbon fiber (Toray Carbon Fibers America Inc., Flower Mound, TX, US) in a composite radiation/ESD shield on the main attitude-control thrusters and as a protective EMI layer on the main engine cover (Fig. 8). Qualified by Lockheed Martin Space Systems (Denver, CO, US) for NASA JPL (Pasadena, CA, US), MIRALON went through testing for mechanical properties, as well as rigorous space qualification procedures for vibration and radiation resistance, and endured a soak test for chemical and water resistance.

MIRALON nonwoven sheet has been used by itself as the outer layer of a laminate for satellite radiation shielding, and also as a web, processed into 100% MIRALON honeycomb for large-scale composite sandwich structures. Here, DuPont, Orbital ATK, Patz Materials and Technologies (Benicia, CA, US) and Boeing Research & Technology (R&T, Long Beach, CA, US) are key development partners. Antoinette claims MIRALON core offers a 300-500% increase in stiffness and 200-300% pick up in compression strength with less weight vs. incumbent products.

This same combination of properties prompted a NASA flight test this year to demonstrate the use of MIRALON fiber in overwrapped propellant tanks. “It provides better hoop strength in a tighter radius than carbon fiber,” claims Antoinette, “and is also able to discharge static electricity to ground.”

In a 2015 NASA EDGE podcast, scientists in NASA’s Game Changing Development Program explained that, using NTI products, they were able to make CNT composites with specific strength double that of carbon fiber composites. NASA senior materials scientist Mia Siochi notes that NASA actually moved away from working with powdered CNTs years ago and now focuses on continuous-format fibers and sheets.

Next-gen products

From NTI’s R&D and product development labs, CW is escorted into the adjoining 2,800m2 Phase II low-rate initial production (LRIP) area. It is empty except for an enclosed 10m by 10m production cell. Antoinette explains this is NTI’s prototype next-generation fiber post-processing line. The plan is to have the entire area filled with low-rate production of MIRALON products by 2018. Although furnaces and production lines occupy less than 50% of the floor space in Phase 1, with the remainder of that space devoted to post-processing, R&D and other functions, Antoinette points out that in Phases 2 and 3, the majority of each space will be devoted to furnaces and production lines, with smaller spaces reserved for other needs, such as post-processing.

“NASA found that for certain high-strength, high-modulus fibers, like IM7 and M463, there is a significant knockdown in properties when you move from fiber to composite form,” explains Antoinette. He claims that MIRALON-reinforced composites do not exhibit this knockdown. “We already have equal strain to IM7 and are almost on par with T1000 in a composite,” Antoinette asserts. “We chemically treat the yarn to align the CNTs, increasing both strength and electrical properties.” The challenge now is to continue boosting strength and modulus to the levels of today’s highest performing fibers, while scaling production without losing MIRALON’s greater strain to failure, which adds ductility to structures. Indeed, NASA is working with NTI to optimize this next-generation fiber. Sochi believes it is possible to produce composites that are 300% stronger than anything now available. “If we can get two or three times the strength of state-of-the-art materials, it makes a mission to Mars possible.”

Meanwhile, NTI is part of the Advanced Functional Fabrics of America (AFFOA) Institute consortium at the Massachusetts Institute of Technology (MIT, Cambridge, MA, US). As part of AFFOA’s mission to help secure US leadership in next-generation fibers and textiles, it is developing the electrical conductivity of CNT fibers for smart structures. Antoinette shows a sample of cloth woven from MIRALON fiber that provides a flexible, yet durable textile Faraday cage. MIRALON-based materials also are being demonstrated in a multifunctional composite structure that uses electrical power to function as a heating element. “We have demonstrated we can repair the structure and restore electrical conductivity,” Antoinette notes. “We are looking at a variety of heated structures and heating devices, including rapid heat blankets like those used in composite repair.”

On the tour’s final stop, Antoinette opens a set of doors that reveal the Merrimack facility’s Phase III area, which is still in the process of build out. The goal is to have this space filled with production by 2020, which will bring the site’s total annual furnace/production line capacity to 20 MT. Although Title III funding enabled NTI’s move into this facility, it also demanded matching funds from non-government sources, which NTI met. The company continues to raise additional funds necessary to complete the Phase II and III expansions, while it secures commercial contracts, initially for cable and ballistic protection applications. “Though these commercial contracts are not for composites,” says Antoinette, “they are enabling the increased capacity and development that will allow composites to be revolutionized by MIRALON products.” Indeed, these commercial contracts differentiate it from many other nanotechnology startups, and are key to the company’s long-term success. Antoinette’s vision includes a facility 10 times the size of the Merrimack site, “We have only just scratched the surface of what these materials can do.”

Related Content

3D weaving capabilities achieve complex shapes, reduce weight and cost

JEC World 2024: Bally Ribbon Mills is displaying film-infused 3D woven joints, woven thermal protection systems (TPS) and woven composite 3D structures.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCAMX 2022 exhibit preview: Bally Ribbon Mills

Bally Ribbon Mills’ highlights its capabilities in design and manufacture of woven structural shapes for hybrid composite structures used in aerospace applications.

Read MoreRead Next

Aligned discontinuous fibers come of age

Discontinuous but aligned carbon fibers are proving formable and formidable in high-performance, compound-curvature applications.

Read MoreAerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

Read MoreTailored Fiber Placement: Besting metal in volume production

Affordable automated production of highly optimized preforms and parts.

Read More