Index rises on surging new orders activity

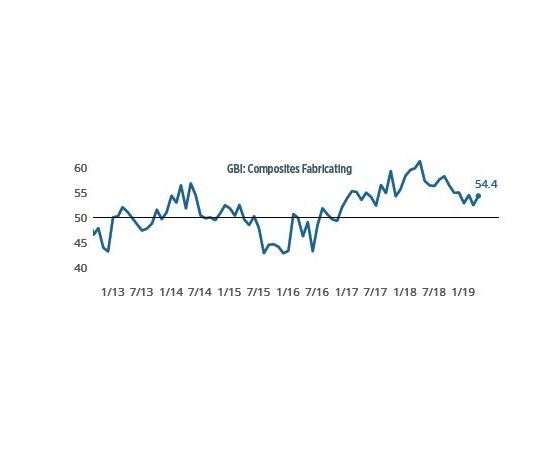

The Composites Business Index moved higher in April 2019 due to strong acceleration in new orders activity.

The Composites Index moved higher in April to a reading of 54.4, up from 52.6 in March 2019, thanks to strong acceleration in new orders activity. The latest Index reading is 12.1 percent lower compared to the same month one year ago, indicating slowing growth within the industry over the past year. Index readings above 50 indicate expanding business activity, while a value of 50 indicates no change and a reading below 50 indicates contracting business activity. Gardner Intelligence’s review of the underlying data indicates that the Index was propelled by new orders, production, supplier deliveries and employment. The Index — calculated as an average — was pulled lower by backlogs and exports; however, only exports contracted during the month.

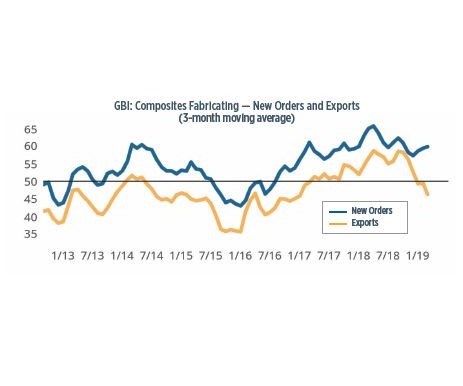

April marked the highest reading for new orders activity in a year, while simultaneously, exports posted its lowest reading since mid-2016. The combination of total new orders expansion and contracting exports implies that domestic demand for fabricated goods more than offset shrinking global demand, according to the survey data. The surge in new orders during April is assumed to have aided backlogs that expanded in April after posting a sharp contraction in the prior month.

More information about the Composites Fabricating Index can be found at http://www.gardnerintelligence.com/

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

.jpg;width=70;height=70;mode=crop)