Composites carry the Curiosity rover to a safe Mars landing

From launch to touchdown, composites performed in flight and stuck the landing!

When engineers at NASA’s Jet Propulsion Laboratory (JPL) were given the job of sending another rover to Mars, they knew they faced a sizeable challenge. The NASA rover mission launched in 2003, for example, involved the twin golf-cart sized (5 ft/1.6m long) Mars Exploration Rovers, Spirit and Opportunity. Each weighed a mere 185 lb/84 kg. The proposed mission, however, would require a rover the size of a mini-compact car — about five times as heavy and twice as long (1,984 lb/900 kg and 10 ft/3m long).

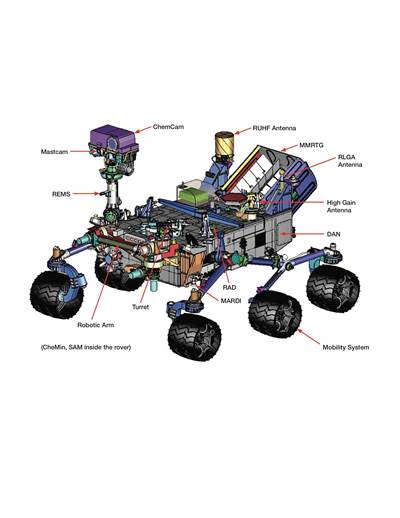

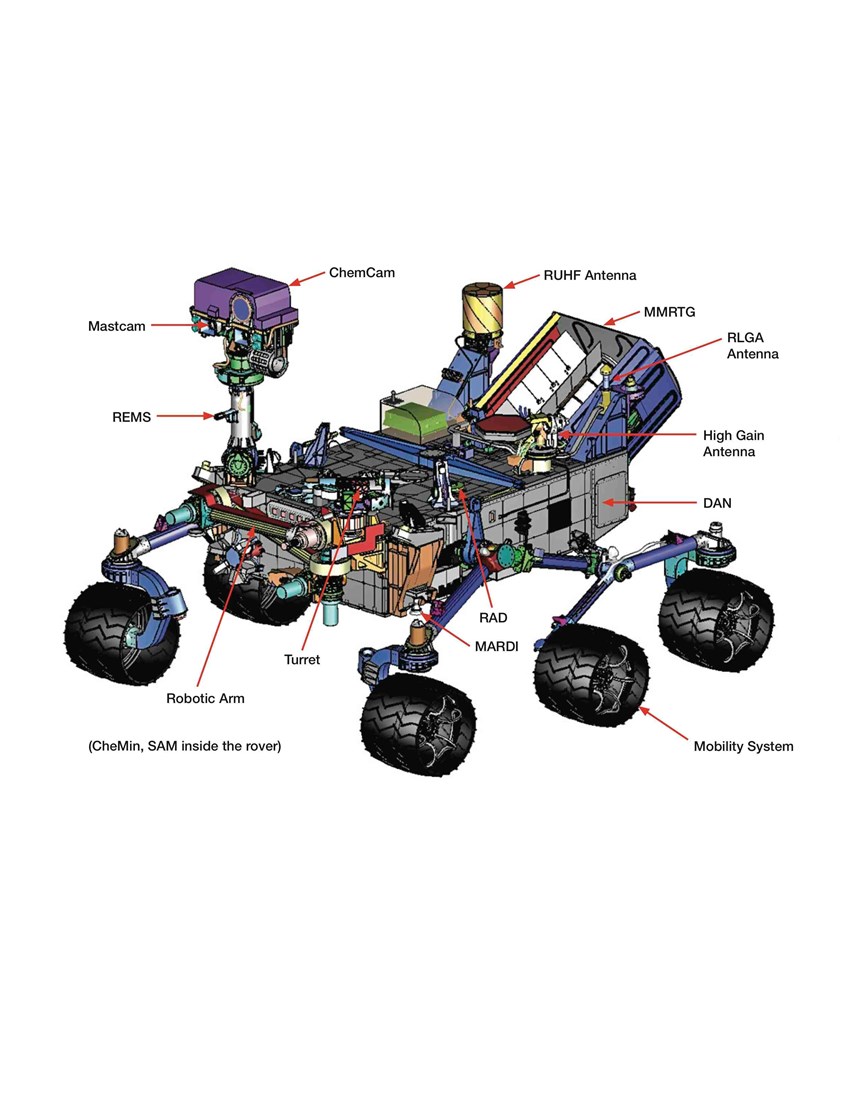

The reason for the substantial size increase is that the rover, nicknamed Curiosity, is more than an explorer — it is a robotic investigator. Officially designated as the Mars Science Laboratory (MSL), Curiosity is exactly that, and its overall mission is to determine the planet’s habitability for humans, as part of NASA’s long-term Mars robotic exploration program. It was equipped to gather samples of Martian rocks and soil, take them on board and distribute them to test chambers inside its 10 analytical instruments.

But first it had to get there.

Protecting precious cargo

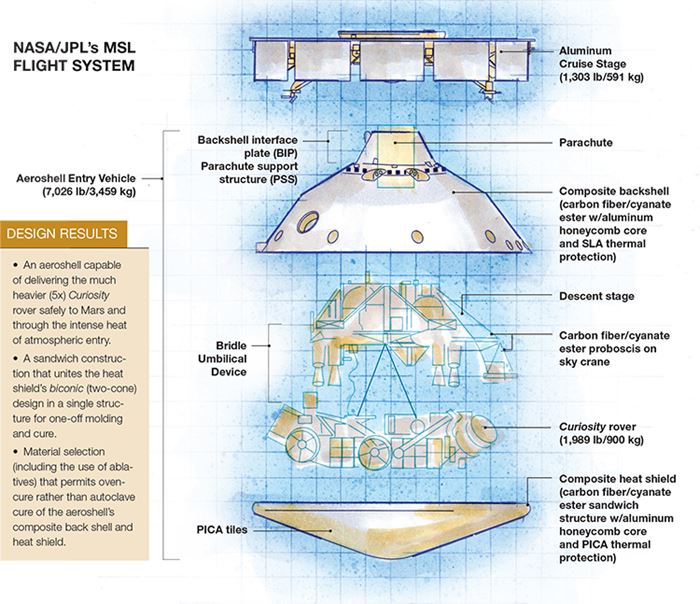

For the 127-million mile trip from Earth to Mars, Curiosity was enclosed inside a spacecraft aeroshell. Comprising a back shell and a heat shield to protect the rover during entry into Martian atmosphere, the aeroshell was jointly designed by JPL and Lockheed Martin Space Systems (Denver, Colo.). Because Lockheed Martin had built all the aeroshells for JPL’s six previous Mars rovers, the MSL engineers were able to call on a considerable design heritage.

Richard Hund, Lockheed Martin’s MSL aeroshell program manager, clarifies that Lockheed Martin considered all the loads that the aeroshell would see throughout its life, including test loads as well as launch and entry loads. Different load cases and different events influence the design of different parts of the structure, he explains. For example, the design of the aeroshell structure’s parts that are closest to the launch vehicle is typically driven by the launch loads.

The primary design loads, however, are sustained during entry into Mars’ atmosphere. “The aeroshell is traveling at a certain velocity,” says Hund. “When it hits the Mars atmosphere, the rover wants to keep driving in at velocity, but friction in the atmosphere is slamming on the brakes.” These pressure loads are transmitted along the primary load path from the heat shield up into the backshell, through the backshell and back down to the rover inside. Entry test loads, then, were more than 100,000 lb-force/45,359 kg-force, enough to safely withstand an entry velocity of ~13,200 mph (5,900 m/sec).

According to David Scholtz, Lockheed’s heat shield principal engineer, the MSL team employed NX NASTRAN to perform finite element analysis of the structure, and MSC Adams dynamic simulation software for Mar’s entry/landing component-separation analyses (MSC Software Corp., Newport Beach, Calif.),

Biconic backshell

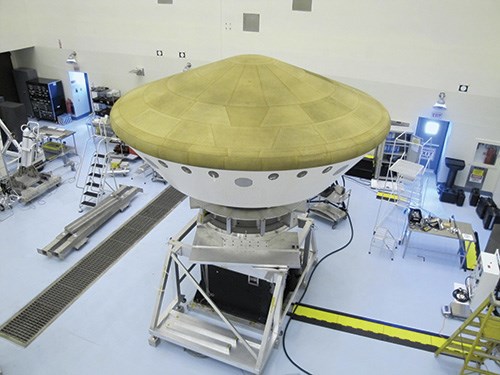

Scholtz says the biggest challenge in designing the MLS aeroshell was to “provide the volume [space] in the aeroshell that JPL needed for the rover within the constraints of the Atlas V launch vehicle and the payload fairing [the expendable clamshell that protects the spacecraft during launch].” The solution was a 15-ft/4.5m maximum diameter asymmetrical biconic backshell and heat shield.

Biconic refers to two cones joined together at their perimeters, but in this case, composites processing enabled Lockheed Martin to build the backshell structure in one large piece by using sandwich construction. The backshell’s structural sandwich is formed with prepreg made with a satin-weave fabric woven from Toray M55J, a high-modulus carbon fiber from Toray Carbon Fibers America (Flower Mound, Texas), in a BTCy-1A cyanate ester prepreg from TenCate Advanced Composites (Morgan Hill, Calif., now Toray Advanced Composites), with a Flex-Core aluminum vented honeycomb core. BTCy-1A is a toughened resin that offers the advantages of low-pressure 350°F/177°C processing, low moisture absorption and negligible volatile emission in space. It has characteristics similar to epoxy, but was developed specifically for service in vacuum as an alternative to epoxy, which is more hygroscopic (water-absorbent) and tends to outgas in a vacuum.

Lockheed Martin hand layed the skins and core over a male mold. The prepreg’s satin weave helped it conform to the part contours. The ply schedule was tailored for stiffness and strength to accommodate the expected loads. Six-inch/152-mm prepreg tape was added in areas that required local reinforcement (e.g., load points for interfaces to other hardware). A proprietary fastening system was designed specifically for the shell’s access doors, to facilitate quick removal and replacement on the launch pad. Notably, the part was oven-cured at 350°F/177°C for about two hours.

Although the backshell is not the first line of defense against the extreme heat generated during entry into the Martian atmosphere, it is in the eddy of the heat wave. For thermal protection, therefore, Lockheed Martin covered the cured backshell with its Super Light Ablator SLA-561V system, a ground cork, silica and phenolic mixture in a silicone binder that is hand packed into a phenolic honeycomb, developed by Lockheed Martin (Bethesda, Md.). After ablator application, the backshell was painted white.

Heat shield

But the backshell was only half of the aeroshell solution. The other half, the heat shield, entailed more than its share of the design challenges, in part, because the increased size and mass of the MSL mandated a different angle of entry than past Mars missions. This resulted in a higher velocity and a more extreme aero-thermal entry environment than previous heat shields had experienced. So the heat shield and its thermal protection system (TPS) were designed to withstand the G-forces and up to 250 watts/cm2 (1,613 watts/in2 or 1.53 BTU/s/in2) of heat, “about 2,500 times what we feel when we walk out into the bright sunshine,” says JPL’s principal engineer Eric Slimko.

SLA-561V was previously used on the heat shields of the two Viking Landers in 1976. Although early tests indicated this TPS solution would also work for the MSL heat shield, Slimko says parameters of shear stress, turbulence and enthalpy (a measure of the total energy of the thermodynamic system) had not been factored into the testing process.

“Unfortunately, matching the four parameters of heat flux, shear stress, enthalpy and turbulence is nearly impossible to obtain in ground test facilities,” Slimko explains. To validate the tests, Slimko’s team developed an approach of matching one or two parameters while straddling the remaining parameters. When enthalpy was matched with shear stress and heat flux, the SLA-561V failed test requirements for MSL entry.

Suddenly, the heat shield material that had served so well during previous safe entries into Martian airspace was deemed inadequate for the landing environment this larger, heavier rover would face. A search for alternatives produced candidates that included a modified SLA 561V, a carbon-carbon with carbon fiber insulation, a fully dense carbon phenolic, and the finalist, phenolic-impregnated carbon ablator (PICA, pronounced peak-a).

Invented at NASA Ames in the early 1990s, PICA comprises a fibrous carbon substrate. Trademarked as FiberForm by Fiber Materials Inc. (Biddeford, Maine), PICA is impregnated with phenolic resin inside a custom-built vessel under proprietary temperature and pressure conditions. During high heat (in this case, entry into Mars atmosphere), the phenolic resin ablates as it undergoes pyrolysis and forms a carbonaceous char.

The PICA was cut into tiles, which were arranged in a structural architecture to meet design specifications for entry forces. Then, the tiles were bonded onto the outer face of the composite heat shield, using HT424 adhesive film, an aluminum-filled, modified epoxy/phenolic resin from Cytec Aerospace Materials (Tempe, Ariz.) and grouted using RTV 560, a low-temperature, two-part silicone rubber compound from Momentive Specialty Chemicals (Columbus, Ohio). The result was the largest — and the first tiled — ablative heat shield ever built.

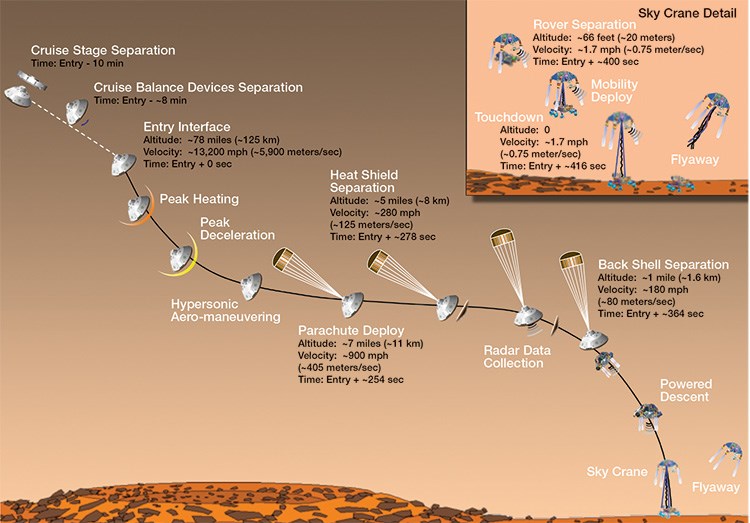

Before final assembly of the aeroshell, Curiosity was tucked into the heat shield, tethered to the JPL-patented sky crane, for final lowering of the rover safely to Mars’ surface after separation from the heat shield, backshell and parachute. Attached to the descent stage by a bridle, or harness, the sky crane, was also connected to the backshell, along with a parachute and parachute support structure (see drawing, at top left). The backshell and heat shield were joined by nine separation fittings. These and other attachment fittings featured pyrotechnically released separation bolts so the heat shield could be separated from the rover and back shell during the Mars descent and the backshell and other descent stage components could be jettisoned during the landing sequence (see Fig. 1).

Satisfying Curiosity

The aeroshell delivered Curiosity, the largest rover yet landed on any planet, unscathed to Mars’ surface in August 2012. In its first year, the MSL established that ancient Mars offered a wet habitat with conditions favorable to microbial life. The rover is now traveling to Gale Crater, where geological layers might yield further evidence of ancient habitability.

When asked if the landing could have been done without composites, Slimko says definitely not. Designers cite their low weight, high stiffness, low coefficient of thermal expansion, exceptional producibility and their capacity to form large, complex shapes and biconic angles.

Related Content

Biteam introduces 3D Noodle International AB spin-off for 3D fabric noodles

Biteam 3D’s third spin-off implements its proprietary 3D weaving technology to produce a variety of carbon, ceramic and other fiber 3D fabric noodle preforms.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

The Curiosity Mars rover: Descent stage composites

Apart from the aeroshell that protected the Curiosity rover during its months in space and Mars descent sequence, only a few other parts of the mission’s descent stage were made from composite materials. Here, HPC identifies and describes them.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)