Composites Academy launches online training with hands-on exercises

Composites Expert and Institut de Soudure partner to provide interactive advanced composites training to students and professionals worldwide.

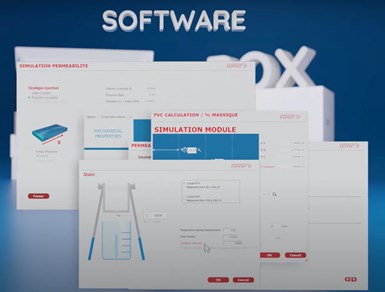

The "E-learning Composites Academy" is an online platform for composites training, designed to be interactive, including engaging software, kits shipped for hands-on exercises, quizzes to check exercise results and knowledge and interaction with a personal tutor for additional help and answers to questions.

The program has been created by Jean-Pierre Cauchois, a 30-year composites veteran and president of Composites Expert (Givry, France). The courses are developed and managed in collaboration with a committee of excellence, comprising composites specialists from industry, research and teaching, and are being distributed globally in partnership with Institut de Soudure (Villepinte, France).

“This is a new way of using digital technologies to train people in composite materials and technology,” explains Jérôme Raynal, aeronautics and composites director for Institut de Soudure. “Students and professionals can access the training from any device and proceed at their desired pace. The goal also is to make learning composites as engaging and interactive as possible.” He notes the courses not only must be reviewed and validated by the excellence committee but are also beta tested during multiple training sessions of roughly 20 students/technicians.

“We are trying to bring a fully remote system for training that maintains technical excellence and quality,” says Jean-Pierre Cauchois. “Our content starts at a very basic level, assuming no prior knowledge, and progresses to a very high level, for example, calculating permeability of preforms for resin infusion.”

Practical exercises

The interactive nature of the specially designed e-classes is augmented through box kits shipped to the student/trainee for practical exercises. These kits contain all necessary supplies and the online course includes tutorials and videos on how to use the kits to set up and perform the exercises. “Each box contains materials for up to nine exercises, depending on the level of training, intermediate or advanced,” explains Auressia Cauchois, E-learning training director at Composite Academy. “Both the difficulty and number of exercises increases with the level of training. The student/trainee will then answer questions about the exercises and their results through a specific interface in the Composites Academy platform.

For the Composites Academy course on resin transfer molding (RTM) and resin infusion, exercises use software for resin flow simulation. “Though we use this to help students understand the infusion process, it is actually an industrial tool that they can keep and use once the class is finished,” Raynal notes. Students and professionals who register with Composites Academy receive a 1-year license which includes all training functionalities within the E-learning platform, including these software tools. The license can be renewed for continued use.

Personal tutors

Every student/trainee is also assigned a tutor, Raynal explains. These tutors are composites engineers at Institut de Soudure. Depending on registrations, each tutor may be assigned several students. “We will follow the student/trainee online, using an email platform to exchange questions and provide assistance when needed,” says Raynal. “As we expand, our goal is to develop companies that will represent us in each country and we will work with them to develop tutors in different languages. Right now, we can train worldwide in English, Spanish, French and Portuguese.”

As this blog was written, 100 students/trainees were registered in Composites Academy. The catalog of courses currently includes an introduction to composites and the intermediate and advanced levels for RTM and infusion. “Our goal is to add new training modules every six to 12 months,” says Raynal. “We are working now to develop classes on thermoplastic composites as the demand and use is growing worldwide.”

Related Content

Automating oxide CMC for higher part volumes

FOX Composites has adapted infusion and RTM for slurry-based matrices, commercializing its VASI and IFOX technologies for automatable, scalable, serial production of high-quality oxide ceramic matrix composite parts, already proven in flight missions and a pilot-scale line.

Read MoreRevisiting the double vacuum debulk process

Evolution of the double vacuum debulk (DVD) process over the years continues to advance its “near autoclave quality” for low-void, highly compacted repair patches.

Read MoreWe4Ce infused 2.5-3-MW rotor blade design passes validation test

Composite rotor blade structure design by We4Ce, mold and prototype production by InDutch Composites and fatigue testing by Suzlon Group has resulted in the novel blade’s IEC61400-5:2020 certification.

Read MoreModular, curved racing track design enabled by composites and adaptive molds

X-Track worked with bespline to develop an easy-to-install, reusable, customizable composite sandwich panel alternative to dirt BMX and motorcross tracks.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More