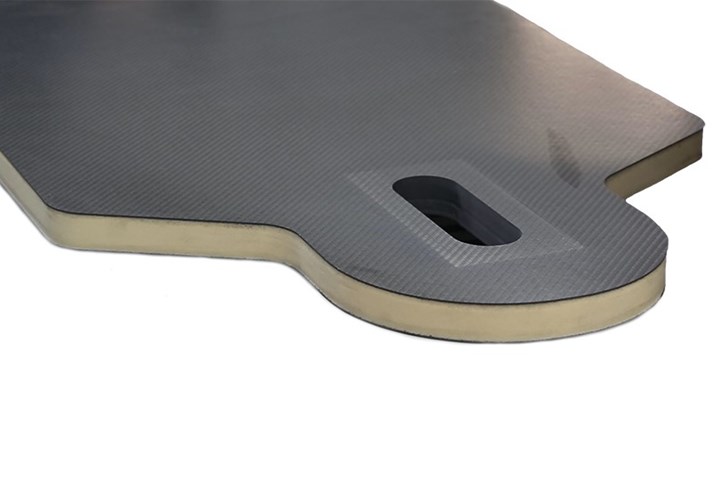

Composite sandwich panels enable flexibility in medical table design

Polyurethane foam core provides a cost-effective option for ACP Composites’ specialized medical positioning table design.

Source | ACP Composites

Family-owned composites fabricator ACP Composites (Livermore, Calif., U.S.) supports a number of industries with its composite structures, plates, flat panels and other custom applications. One successful application of its sandwich composite panels is a carbon fiber composite patient positioning table designed for healthcare equipment company Broncus Medical Inc. (San Jose, Calif., U.S.).

According to Justin Sparr, CEO of ACP Composites, to meet customer requirements the table needed to be both lightweight and durable, transparent to x-ray radiation, and able to be easily machined to accommodate a specific type of insert for the attachment of medical instruments and clamps. To meet volume and cost requirements, the tables also needed to be produced cost-effectively with short lead times. Carbon fiber was chosen for its low energy absorption and low attenuation — meaning the material, unlike metal, reduces the intensity of the x-ray beams as they hit the surface, rather than scatter the beams and risk unnecessary exposure to the patient. ACP Composites chose Axiom Materials’ (Santa Ana, Calif., U.S.) 3K twill carbon fiber prepreg for use in the sandwich panels.

For the core, metal honeycomb core was not possible due to high attenuation, and polyacrylamide foam, which Sparr says is often used in these types of tables, was outside of the target price range and required expensive tooling to cure. For this application, ACP decided to use LAST-A-FOAM FR-3700 series polyurethane foam core from General Plastics (Tacoma, Wash., U.S.) for use within the sandwich panels.

In this application, polyurethane foam enabled the panel for the table to be produced quickly, with the same dimensional stability and imaging clarity as polyacrylamide foam at a lower price point.

According to Sparr, ACP has been a customer of General Plastics for more than 20 years, using the company’s polyurethane foam products for a variety of non-aerospace foam core and sandwich panel applications. “We’ve tried and tested every foam you can imagine,” Sparr adds. “I’ve had foams catch on fire, some have even collapsed during processing. Other foams that could do the job were over-priced or had too long of a lead. So, it would restrict us from carrying out our commitment to continuously meet our customers’ delivery and production schedules.”

In this application, General Plastics’ foam enables the panel for the table to be produced quickly, with the same dimensional stability and imaging clarity as polyacrylamide foam at a lower price point. The low-density, highly machinable foam core also enables ACP to install specialized carbon fiber inserts within the panel, giving the option to drill a hole through it or bolt into it.

General Plastics says that FR-3700 is a rigid, closed-cell, flame-retardant polyurethane foam available in a range of densities. Tougher and less friable than other rigid foam materials, this aerospace-grade, BMS 8-133-qualified foam is said to enable cutting of crisper edges, making it well-suited to machining complex shapes for composite cores. It also exhibits a high strength-to-weight ratio due to its cellular structure and cross-linked resin. LAST-A-FOAM FR-3700 is said to have high resistance to water absorption, and will not swell, crack or split with exposure to water. This series is non-abrasive and can be machined with standard high-speed steel (HSS) cutting tools.

To build the tables, the polyurethane foam is first skimmed, then processed in a large press for curing — five to ten at a time, Sparr says. The blocks of foam are then machined to the correct shape, and the carbon fiber laminate is hand-laid over top of the foam before the whole panel is cured again.

The medical positioning tables have now been produced commercially by the customer for about three years, Sparr says.

Related Content

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreAMSL Aero partners with CareFlight for Vertiia aeromedical fit-out

Together, AMSL Aero’s long-range eVTOL aircraft will enable CareFlight to provide direct services from remote sites directly to hospitals.

Read MoreMulti-material, self-sensing, 3D-printed scoliosis braces

Startup Fited and Brightlands Materials Center have developed a lighter weight, thinner CFRP corrective brace, including pressure sensors made from continuous carbon fibers.

Read MoreCityAirbus NextGen to be developed for future medical missions in Norway

Airbus and the Norwegian Air Ambulance Foundation partner to measure the added value of eVTOL aircraft for medical use cases across Norway.

Read MoreRead Next

Kordsa targets phenolic-based sandwich panel toward aircraft interiors

The sandwich panels comprise glass fiber/phenolic skins surrounding a Nomex honeycomb core.

Read MoreFrom the CW Archives: The tale of the thermoplastic cryotank

In 2006, guest columnist Bob Hartunian related the story of his efforts two decades prior, while at McDonnell Douglas, to develop a thermoplastic composite crytank for hydrogen storage. He learned a lot of lessons.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;width=70;height=70;mode=crop)