Gripper attachment precisely handles rolled materials

CAMX 2023: The Autometrix Fusion Gripper, complementary to Radium or Argon cutting systems, easily grips and pulls materials with minimized direct contact and reduced manual effort.

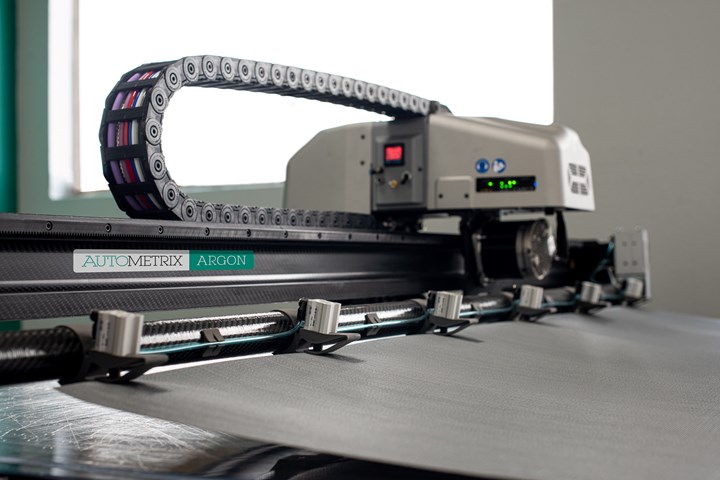

As the company continues to innovate and develop various models and platforms of cutting machines, Autometrix (Grass Valley, Calif., U.S.) remains committed to providing customers with the best solutions for accurately handling rolled goods. Its latest offering, the Fusion Gripper, is designed with versatility and durability in mind. Operation is simplified via seamlessly integrated controls in the cutting machine’s touchscreen and PatternSmith software.

The Autometrix Fusion Gripper serves as the ideal complement to the company’s Radium or Argon cutting systems. It functions as an attachment, enabling users to effortlessly grip and pull materials from Autometrix’s diverse range of material rack systems. When paired with the Radium/Argon cutting system, the Fusion Gripper is programmed to retrieve material from the cutting bed and unroll it to a precise home position — especially useful when working with wide materials that traditionally require the assistance of two individuals. Proprietary “grip fingers” are purposefully designed to securely hold the material throughout the pulling process. Moreover, the Fusion Gripper’s construction incorporates a robust carbon fiber beam, ensuring its resilience and longevity under demanding industrial use for many years to come.

The genesis of the Fusion Gripper can be attributed to feedback and requests received from Autometrix customers expressing a need to minimize direct contact with the material to enhance accuracy and achieve precise squareness. Addressing this demand, the Fusion Gripper delivers high precision and is said to significantly reduce the manual effort required to pull the material by hand. By streamlining operations and mitigating unnecessary movement, the Fusion Gripper optimizes workflow efficiency while maintaining the utmost accuracy in material handling.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

-

Reusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

-

What to expect at CAMX 2022

The Composites and Advanced Materials Expo (CAMX), the largest composites industry trade event in North America, takes place Oct. 17-20, 2022 in Anaheim, Calif., U.S.

.jpg;maxWidth=300;quality=90)