Bladder and caul solutions for trapped & complex composites fabrication

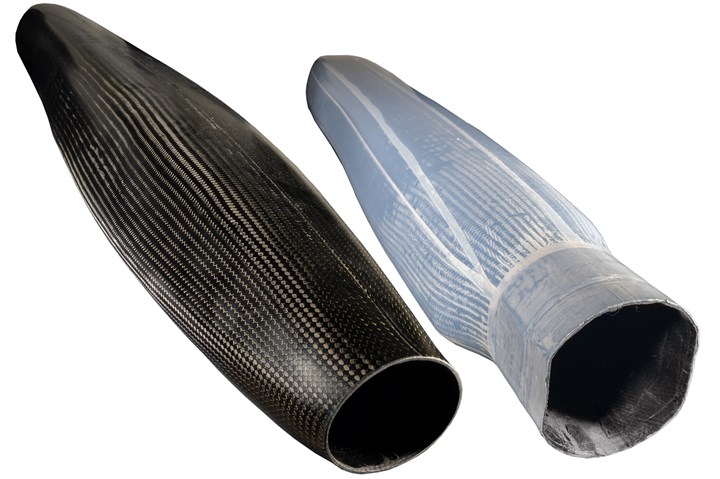

Smart Tooling reviews the function and application of its shape memory polymer tooling bladder and caul solutions for the efficient and cost-effective manufacture of trapped and complex geometry composite parts and structures.

Advanced tooling materials specialist Smart Tooling (Xenia, Ohio, U.S.) has developed reusable shape memory polymer (SMP) tooling solutions that provide a dynamic modulus response to changes in temperature. Such SMP tooling can change from a rigid state to an elastic state when heated above their glass transition temperature (Tg). In an elastic state, they can be stretched or deformed up to 10% biaxially and simultaneously. If SMPs are cooled in a deformed shape, they will retain that shape when their temperature drops below the Tg. Further, when the SMP tooling is heated without restraint, it will attempt to return to its original fabricated shape.

In this Digital Demo, Smart Tooling’s CEO, Craig Jennings, and VP of Engineering, Tom Margraf, explain a little about Smart Tooling’s history and then provide a detailed explanation about SMP tooling technology, product solutions that behave like bladders and cauls, and case studies in which Smart Tools that behave like bladders and cauls have been applied to cost-effectively and efficiently solve difficult composite manufacturing challenges.

Photo Credit: Smart Tooling

Related Content

-

Digital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

-

Digital Demo: Secure Vacuum Bag Seal Eliminates Single-Use Sealant Tapes in Closed Mold Process

Magnum Venus Products (MVP) has developed a reusable two-part seal for the vacuum infusion closed mold process, replacing single-use sealant tapes. (Sponsored)

-

Digital Demo: Aerospace Carbon Fiber Infusion

Learn how this process combined with carbon fiber can offer the manufacturer the benefits of increased strength and the ability to make a lighter-weight part.