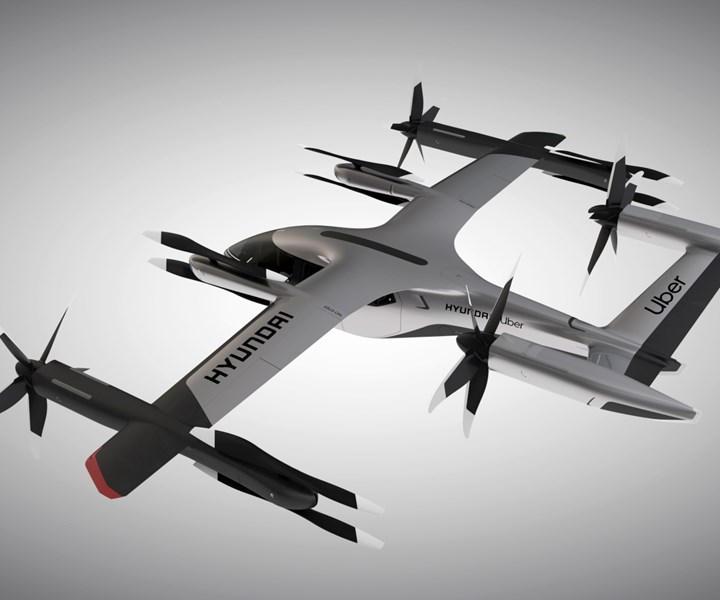

Hyundai Motor Co., Uber unveil air taxi model

At the Consumer Electronics Show (CES), the companies announced an aerial ridesharing partnership and a new eVTOL design.

Source | Hyundai Motor Co. and Uber Elevate

On Jan. 6 at the Consumer Electronics Show (CES, Las Vegas, Nev., U.S.), rideshare company Uber (San Francisco, Calif., U.S.) and aHyundai Motor Co. (Seoul, South Korea) unveiled a full-scale air taxi concept and announced a new partnership to develop air taxis for use in a planned future aerial rideshare network.

Hyundai is the first automotive company to join the Uber Elevate initiative, with plans to bring its automotive-scale manufacturing capability and a track record of mass-producing electric vehicles. The air vehicle concept Hyundai released at CES was created in part through Uber’s open design process, a NASA-inspired approach that jump-starts innovation by publicly releasing vehicle design concepts so any company can use them to innovate their air taxi models and engineering technologies.

Source | Hyundai Motor Co. and Uber Elevate

Through this partnership, Hyundai will produce and deploy air vehicles, and Uber will provide airspace support services, connections to ground transportation and customer interfaces through an aerial ride share network. Both parties are collaborating on infrastructure concepts to support take-off and landing for this new class of vehicles.

Hyundai has worked with Uber Elevate to develop the S-A1 personal air vehicle (PAV) model, which is intended to optimize electric vertical take-off and landing (eVTOL) aircraft for aerial ridesharing purposes.

According to the companies, the S-A1 model unveiled at CES:

- is designed for a cruising speed up to 180 miles per hour (290 kilometers per hour), a cruising altitude of around 1,000-2,000 feet (300-600 meters) above ground, and to fly trips up to 60 miles (100 kilometers);

- will be 100% electric, utilizing distributed electric propulsion and during peak hours will require about five to seven minutes for recharging;

- utilizes distributed electric propulsion, powering multiple rotors and propellers around the airframe to increase safety by decreasing any single point of failure;

- is designed to take off vertically, transition to wing-borne lift in cruise, and then transition back to vertical flight to land;

- will be piloted initially, but over time will become autonomous; and

- is designed with a four-passenger cabin.

“Our vision of urban air mobility (UAM) will transform the concept of urban transportation,” says Jaiwon Shin, executive vice president and head of Hyundai’s Urban Air Mobility Division. “We expect UAM to vitalize urban communities and provide more quality time to people. We are confident that Uber Elevate is the right partner to make this innovative product readily available to as many customers as possible.”

“Hyundai is our first vehicle partner with experience of manufacturing passenger cars on a global scale. We believe Hyundai has the potential to build Uber Air vehicles at rates unseen in the current aerospace industry, producing high quality, reliable aircraft at high volumes to drive down passenger costs per trip. Combining Hyundai’s manufacturing muscle with Uber’s technology platform represents a giant leap forward for launching a vibrant air taxi network in the coming years,” says Eric Allison, head of Uber Elevate.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

.jpg;width=70;height=70;mode=crop)