GKN Aerospace and KTH to develop electric fan thruster

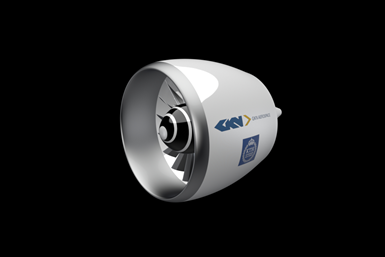

The organizations will work jointly to develop fan technology for smaller regional aircraft. The project will study aerodynamic design, performance, noise and manufacturing technology for a nested fan powered by electricity.

GKN Aerospace (Redditch, U.K.) and KTH (Stockholm, Sweden) — the Swedish Royal Institute of Technology — are jointly developing fan technology for smaller regional aircraft.

The project, which kicked off in July 2021, will study aerodynamic design, performance, noise and manufacturing technology for a nested fan powered by electricity, either from batteries, hydrogen fuel cells or even more conventional hybrid propulsion solutions. The project is supported by the Swedish Energy Agency (Eskilstuna, Sweden).

The proposed propulsion solution, which features a nested fan instead of a conventional propellor, is said to offer significant advantages in safety, noise level and engine installation.

According to GKN, Europe's aviation industry has adopted an ambitious roadmap to achieve net-zero emissions by 2050. Parallel development of different types of propulsion solutions for aircraft engines is one of the important steps to take. GKN Aerospace and KTH hope to make a vital contribution to this technology step.

Henrik Runnemalm, vice president of GKN’s Aerospace Global Technology Centre, says, “We are very positive about this initiative, which helps us to become part of the solution to aviation’s climate challenge.”

Related Content

-

Protecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

-

JEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

-

The basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.