Daher acquires KVE Composites Group

The acquisition is intended to extend Daher’s thermoplastic composites capabilities for structural aircraft components.

Daher (Paris, France) on June 3 announced that it has acquired KVE Composites Group (The Hague, Netherlands) with the goal of extending its thermoplastic composites capabilities for structural aircraft components. The acquisition is part of Daher’s “Succeed Together” strategic plan for 2018-2022.

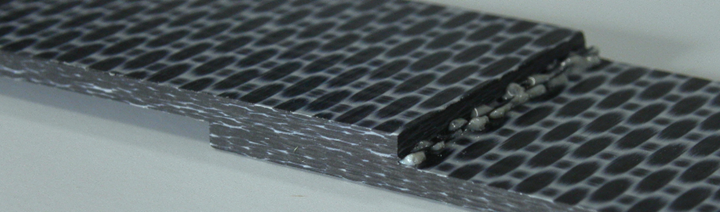

Daher currently is the leading European supplier of thermoplastic components, with 160,000 components total, and with the new acquisition the company intends to draw on KVE Composites Group’s experience and expertise in the induction welding of thermoplastic composite components. This process reportedly will enable a 75% reduction in the number or rivets used to assemble aircraft fuselage structures, leading to financial savings and a weight reduction of 15%.

A thermoplastic composite component produced by KVC Composite Group. Source | Daher

As part of this acquisition, Daher intends to position itself as a leader of thermoplastic composites technology for areostructures. According to the company, these materials and technologies will become increasingly important in aerospace for benefits such as weight reduction, lower consumption, productivity and aircraft competitiveness.

“The acquisition of KVE Composites Group will accelerate the development work we are doing on more complex applications of thermoplastic composite materials as part of offering our customers increasingly effective solutions," says Didier Kayat, CEO of Daher.

Additional branches of Daher’s strategic plan include the launch of its TBM 940 single-engine turboprop airplane, which features an automated throttle and automatic deicing system; plans to expand business to North America; and partnerships with blockchain and artificial intelligence startups.

“Our strategic plan for 2018-2022 continues to be implemented across the piece, and the Group is on track to capture the value generated by its priority initiatives,” says Kayat. “In combination with our capital investment program and long-term vision, the commitment, innovative expertise and energy of our teams give me real confidence in the continued growth of Daher.”

Read more about current and future uses of thermoplastic composites for next-generation commercial aircraft: “Thermoplastic composites: Poised to step forward.”

Related Content

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Paris Air Show 2023 highlights

The Paris Air Show, one of the largest aerospace trade shows in the world, returned for the first time since 2019 and proved that the global aviation industry industry is very much alive and kicking.

.jpg;width=70;height=70;mode=crop)