AC Marine & Composites to build composite blades for 2-MW tidal turbine

The 2-megawatt tidal turbine will feature four 10-meter composite blades, and is expected to be the most powerful tidal turbine to date.

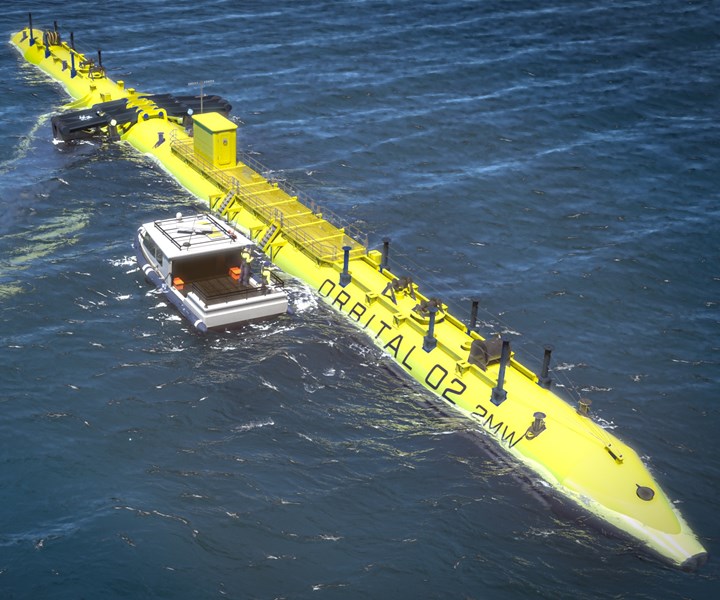

The O2 2-megawatt tidal turbine. Source | Orbital Marine Power Ltd.

AC Marine & Composites Ltd. (ACMC; Gospart, U.K.) has been awarded a contract to supply composite blades for floating tidal stream turbine developer Orbital Marine Power Ltd.’s (Orbital; Orkney and Edinburgh, U.K.) first commercial O2 tidal turbine. ACMC will manufacture the blades at its facilities in Gospart, Hampshire, U.K.

According to Orbital, ACMC will build 10-meter composite blades for both of the O2’s twin rotors, with four blades in total, giving the machine a swept area of more than 600 square meters. Orbital says this is the largest ever on a tidal turbine.

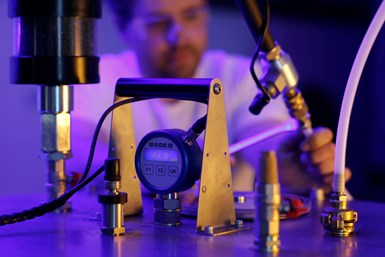

Bespoke resin injection machine from AC Marine & Composites. Source | Orbital Marine Power Ltd.

The O2, capable of generating more than 2 megawatts of power from tidal stream resources, will reportedly become the world’s most powerful tidal turbine when it enters operation later next year as part of a long-term project at the European Marine Energy Centre in Orkney, Scotland. Improvements in Orbital’s platform design have allowed for a rotor diameter increase of 4 meters on the company’s previous, record-breaking 2-megawatt SR2000 turbine, and the O2 will be capable of producing electricity for more than 1,700 U.K. homes.

“AC Marine & Composites have an impressive track record in delivering high-quality composites solutions to a range of sectors including marine energy. We are delighted that they are supporting the commercialization of our technology through the O2 project,” says Andrew Scott, CEO of Orbital.

Related Content

-

JEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

CompositesWorld is on the road again

Since CW’s infancy, its editors have strived to imbue its coverage with a sense of place, whether that’s through plant tours, facility visits or trade shows. After a pandemic, this has never seemed more important.

.jpg;width=70;height=70;mode=crop)