Solving the puzzle of different external and internal influencing factors to define the optimal point in time to demold for every part produced requires a holistic approach.

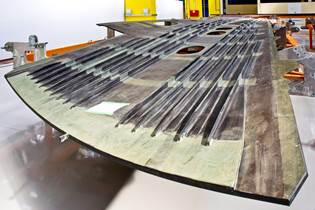

The sensor and data analytics technology developed by sensXPERT has demonstrated its capacity to reduce cure cycles by up to 30% in processes such as RTM, infusion, autoclave, and oven curing of composite components. This technology empowers manufacturers to gain insights into the curing process, including parameters like glass transition temperature (Tg) and the degree of cure. However, it's important to note that cycle time is only scratching the surface.

Discover a holistic approach to optimizing composite production processes with sensXPERT and Mississippi State University in this webinar. Learn about how increasing energy savings and waste reduction potential can support customers in reaching their ESG (environmental, social, and governance) goals to achieve more sustainable composite part production processes.

Agenda:

- Existing state of sustainability in the composites and plastics manufacturing industry

- The value of resin infusion processes and technologies, along with the development of materials, processes, and equipment to enable low-cost, high-rate manufacturing

- How an aviation industry leader was able to optimize its manufacturing processes with machine learning and adaptive process control