Improvements over the past decade include using UD tapes (vs. fabric), computer modeling, sensors for process control, standardized tests for airframe certification and more. The industry’s leading experts will present their status in advancing induction welding for future production aircraft and answer your questions.

Agenda:

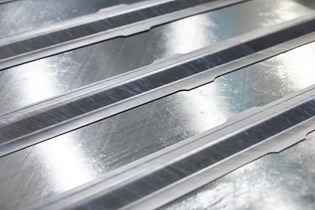

- Qualification of induction welding using CF/LM PAEK UD tape

- Demonstrations of induction welding for industrial assembly and using AI-based process control

- Testing of new sensors for process control

- Fuselage Tier 1 supplier view of fit into production