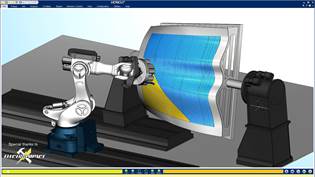

For most companies, the idea of a digital twin is purely theoretical. The path towards implementing, and more importantly, benefiting from a digital twin is not clear. This presentation will highlight practical challenges as well as real-world benefits of the digital twin. Though the implementation is not trivial, a digital twin offers newfound opportunities to leverage gathered data to both optimize programs and allow for continuous improvement. Examples of potential optimization include part analysis resulting from manufacturing conditions, closed-loop feed rate optimization factoring in feature-based controls and their effect on layup quality, and upstream traceability of root causes to downstream issues.

Primary Topics:

- What is a digital twin, and how is it used today?

- Requirements to compile an effective virtual model

- How to leverage the power of a digital twin to optimize your process

Presenter:

Charles Anderton

Composites Product Specialist, CGTech

Mr. Anderton has been involved with Automated Composites Manufacturing from the point of view of NC programmer, machine operator, manufacturing engineer, and project engineer. Prior to joining CGTech in January 2016, he held a position with Aurora Flight Sciences as a Six Sigma Green Belt Manufacturing Engineer in Columbus, MS. At CGTech he focuses on Vericut's Composite Application's product development as a Composites Product Specialist. Mr. Anderton has worked with CGTech's composite product line as an end user since 2014 and in support of development since 2016.