Thermoplastic tubulars: Robust flexibility for offshore wells

In the oil and gas industry, a fiber-reinforced thermoplastic composite pipe (TCP) system from Airborne Composite Tubulars (The Hague, The Netherlands) is providing a less-expensive alternative to the traditional “rig” for flushing subsea wellhead stacks and injecting glycol under pressure.

In the oil and gas industry, increased oil recovery (IOR) from existing wells is a priority, and well intervention (for diagnostics, inspection, maintenance, or production improvements) plays a vital role. Intervention on subsea wells, historically, has required a traditional but expensive “rig” to flush subsea wellhead stacks and inject glycol under pressure. Today, offshore operators, such as TSMarine (Aberdeen, Scotland, U.K.), are turning instead to riserless (rigless) alternatives that circulate fluids using more cost-effective composite tubulars.

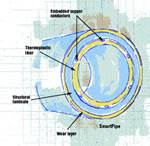

One option is a fiber-reinforced thermoplastic composite pipe (TCP) system from Airborne Composite Tubulars, a business unit of Airborne International (The Hague, The Netherlands). The company’s managing director, Martin van Onna, says TCP’s “one-material concept” optimizes the structural interfaces between layers and largely eliminates rapid decompression issues. “This pipe structure consists of a liner reinforced with melt-fused carbon or glass fiber tapes,” explains van Onna. Preimpregnated with the same thermoplastic compound as the liner, which can range from polyethylene (PE) to polyetheretherketone (PEEK), the tapes are sourced from Ten Cate Advanced Composites (Nijverdal, The Netherlands), Ticona (Florence, Ky.) and Suprem SA (Yverdon-les-Bains, Switzerland). “Melt-fusing fiber tapes onto the tubular enables longitudinal reinforcement, creating a pipe with high tensile strength and allowing for sufficient spoolability without fatigue,” he explains. “The pipe is then coated again using the same thermoplastic material, which results in a fully bonded pipe system without any adhesives.”

TCP intervention lines reportedly outlast those made of steel coiled tubing, which has a short 30- to 50-cycle useful life and low chemical resistance; they also outlast thermoset composite tubulars, which are considerably more brittle than thermoplastics. According to van Onna, high tensile strength, collapse ratings and internal pressure ratings give TCPs great potential in a variety of applications. In fact, Airborne reports that 10 TCP projects will be fielded this year for companies such as StatoilHydro (Stavanger, Norway) and Shell (The Hague, The Netherlands), not only for subsea intervention but riser and drilling applications as well.

Related Content

-

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Plastic injection to composite overmolding: Evolving mold design for lightweight manufacturing

Hybrid molding is increasing for faster, high-volume production of more integrated parts, but success requires process knowledge which includes new mold developments as processes converge.