Residential construction breakthrough: Composites find a home

Composite materials get the go-ahead for an unconventional but code-compliant California house.

Engineering Challenge:

Construct a two-story residence using materials that makes its unique, curved shape configuration practically possible yet compliant with building codes and local fire ordinances.

Design Solution:

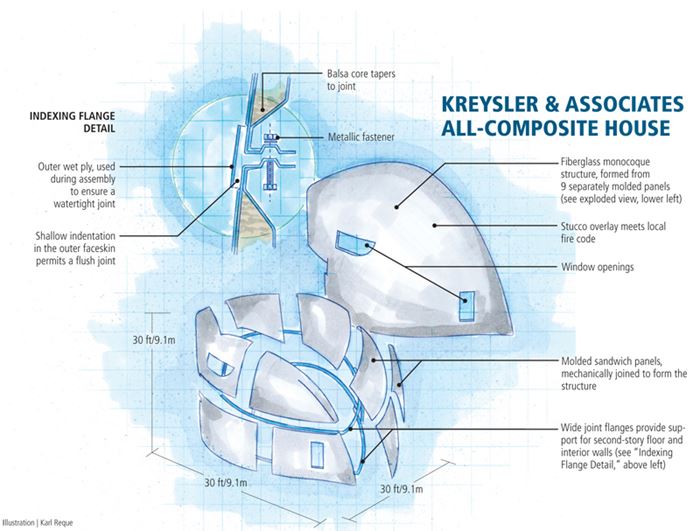

A composite monocoque formed from nine molded fiberglass-skinned sandwich panels that could be fabricated, tested and transported easily to the building site and assembled with straightforward joining details.

Many composites practitioners bemoan the fact that construction engineers and architects won’t recognize material innovations. The construction industry is too conservative. Traditional materials are too entrenched. Composite materials are too new. So go the arguments. But architectural composites specialist Bill Kreysler, the owner of Kreysler & Associates (American Canyon, Calif.), would argue the opposite is true: “Engineers must innovate to compete, and their clients are hungry for innovation,” Kreysler claims. “Traditional materials are vulnerable today — new approaches, based on ‘green’ technology, versatility and sustainability, are becoming very important.”

To prove his point, Kreysler’s fiberglass-manufacturing facility recently fabricated an all-composite house near San Francisco, Calif. The curved, two-story residence was the recipient of the Best in Show ACE award at the American Composites Manufacturers Assn. Composites 2010 exhibition. (To see our post-show coverage, click "Composites 2010 ...." under "Editor's Picks," at right). The story of its development is a showcase for how composites can be mainstreamed in architectural design and construction.

From art to part

The home’s instructive history began with a stunning property overlooking San Francisco Bay. Inspired by the site and its natural materials and shapes, the project’s design principal Miranda Leonard created a 12-inch/305-mm plaster model of a two-story living quarters intended as the focal point of a proposed walled compound. Leonard and Walker & Moody Architects (San Francisco) spent more than a year in search of an engineering firm willing to build the unusual rounded, wedge-shaped structure.

“The people they contacted were trying to come up with curved metal frames, elaborate wooden beams,” says Kreysler. “Traditional means and methods just couldn’t work cost-effectively with this shape.” Eventually, Walker & Moody connected with Kreysler’s company through structural engineer Juri Komendant, who agreed with Kreysler that a monocoque structure, without internal framework, could be realized easily with composites.

Kreysler’s team scanned the plaster model using a Cyberware laser digitizer, or LADAR, manufactured by Cyberware Inc. (Monterey, Calif.). This step yielded an initial shape that could be input to Rhino3D software from Robert McNeel & Assoc. (Seattle, Wash.). The Rhino program translated the scanned data points of the model’s NURBS (nonuniform rational B-splines) — mathematical representations of its complex three-dimensional (3-D) geometry. Rhino was used to scale-up the shape data 30 times, to create accurate full-size, 3-D surfaces (about 30 ft/9.2m in each dimension). This shape was exported into AutoCAD software (Autodesk Inc., San Rafael, Calif.) to enable Kreysler engineers to create shop drawings.

Although composites were the clear answer for the home’s design, it was not clear how to obtain building permits from local authorities: In essence, there are no codes for structural composites in the International Building Code (IBC), although important progress has been made toward that end (click on the sidebar at the end of this article). Without a prescriptive code to follow, the only alternative for this unusual structure was to employ a performance-based approach, which is allowed on a case-by-case basis. In this case, it was determined that the structure would be designed and, if necessary, tested under the supervision of Komendant, who would then sign the drawings, certifying that it would meet the intent of the code.

Komendant interpreted the local codes for Type 4, single-family dwellings and determined the various loads that the building would have to withstand, including wind and earthquake loads, and the dead loads imposed by the second floor and overall structure. He worked closely with independent engineer Kurt Jordan, a finite element modeling specialist. Using ANSYS software (ANSYS Inc., Canonsburg, Pa.), Jordan determined the structure’s performance under the various load cases and arrived at a laminate design: a balsa-cored sandwich panel, with 2-inch/50-mm thick core and 0.1875-inch/4.76-mm thick woven fiberglass/glass mat skins wet out with vinyl ester resin from proprietary suppliers. Sandwich design was preferred over a monolithic (uncored) laminate, says Kreysler, because the cored sandwich provided greater stiffness and thus less deflection, and also provided some insulation value.

From part to parts

Kreysler and Komendant initially wanted to build the house as a single part. “Unfortunately, we were not able to obtain permits for a helicopter to fly the complete house into the location, so the one-piece idea was out,” says Kreysler. Instead, the overall shape was broken into nine segments that would be molded separately for assembly later on site. How and where to break up the curved two-story wedge was determined in Rhino. Decisions were dictated, in part, by the work envelope of Kreysler’s in-house milling machine, truck transport considerations, and the need for segments that were “reasonably manageable and stable,” adds Kreysler.

The segmented design approach required a water- and weathertight joint design, and associated tooling details for each of the nine components. Kreysler’s manufacturing team, led by production design engineer Serge Labesque and production foreman Tim Oliver, devised keyed panel joints, referred to as indexing flanges, as shown in the drawing above.

The layup was designed such that the balsa core would taper at the edge of each tool, and the two skins would be overlapped to form a flange approximately 2 inches/50 mm wide. Small tooling details, called buttons, were placed at intervals along the tool edges. When the overlapped skin plies were pressed up against them and cured, the buttons would form indentations along the flanges, which could be drilled later to accept the metallic fasteners that would secure the segments when they were joined. The flanges would double as supports for interior walls and floors.

In addition, the tools were designed to yield a shallow indentation in the outer faceskin adjacent to the joining flange: “This step detail allowed us to wet-laminate a ply of fiberglass over the segment joints during the onsite construction to ensure a watertight joint, yet maintain a flush, smooth outer surface,” Oliver explains.

Segment fabrication began with CNC machining of large blocks of expanded polystyrene (EPS) foam to create an inexpensive, one-off female mold for each segment, incorporating the tooling details described above. After sealing the foam to prevent any reaction between it and the resin, the sandwich panels were layed up by hand and cured at ambient temperature over several days. The challenge at this stage was the owner’s mandate that there be no residual chemical odors in the finished house. “To comply with that, we had to postcure the entire structure!” asserts Kreysler. Indeed, the segments were drilled and assembled outside the company’s facility, and a makeshift oven was devised by draping a huge canvas tarp over the structure (see bottom photo). Large portable heaters maintained a temperature of 190°F/88°C for three days to completely crosslink the resin and eliminate any subsequent offgassing.

Another challenge was presented by the local fire department, which required Class-A fire resistance for the home’s roof due to its location adjacent to designated “open space,” where brush fires can occur. Because there was no roof per se, fire officials decided that the entire curved surface would have to comply with the Class-A standard.

The Kreysler team opted to retain a fire protection engineer, Fred Fisher of Fisher Research & Development (Vacaville, Calif.), to help test the composite design under conditions that would simulate exposure to a brush fire. Fisher helped the Kreysler team devise a setup consistent with ASTM E108, “Standard Test Method for Fire Tests of Roof Coverings,” then supervised an E108 roofing test at a certified testing laboratory. The test method involves placing a panel of the roofing system in the path of a 12 mph wind blown by a fan through a gas fire, then placing a “burning brand,” or a grid of flaming wooden boards onto the panel. According to the test, the brand cannot burn through to the panel’s underside, nor can any portion of the panel be blown off or fall away and become a “flaming brand” or even a “glowing particle” that could, in turn, ignite additional fires. While the composite test panel did not burn through during the test, because it was fabricated with a Class I vinyl ester system with fire-retardant additives, it developed a surface char layer that was deemed unacceptable because hot particles could potentially blow off the surface. To eliminate the char, Fisher recommended a 0.25-inch/6.35-mm layer of Portland cement-based stucco be applied to the entire outer surface. Unfortunately, reports Kreysler, the stucco would not bond directly to the fiberglass, so an adhesive bonding agent was pre-applied to ensure the stucco would adhere.

After the parts were transported to the site, attached to the foundation bolts and assembled, and stucco applied, structural testing was undertaken to show that the house panels could handle the design loads predicted by the model. Komendant simply used stacks of sandbags to apply loads in key locations and monitored the resulting strain on the panels with strain gauges. In every case, the field tests were consistent with the ANSYS model results, which facilitated inspector approval.

“We were pleased with the project and it couldn’t have been accomplished without composite materials and methods,” conclude Leonard and Kreysler. Adds Kreysler, “Until recently, this method of construction was considered too ‘unconventional’ to be taken seriously. Now, with the acceptance of composite materials or FRP by the International Code Council (ICC), authors of the IBC, this barrier no longer exists.”

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreRead Next

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreCW’s 2024 Top Shops survey offers new approach to benchmarking

Respondents that complete the survey by April 30, 2024, have the chance to be recognized as an honoree.

Read More

.jpg;maxWidth=300;quality=90)