Share

Entry deadline extended to January 22, 2023.

Competition is in the air, as MCG Advanced Materials Division has announced the Composite Engineering Challenge, a challenge for carbon fiber parts manufacturers. The challenge is designed to help startups and scale-ups to move to higher production levels for lightweight parts made from carbon fiber-reinforced composite materials (CFRP). The winner of the Challenge will receive scale up support from Mitsubishi Chemical Group. This production package is valued at $25,000 and will be tailored to the winning team’s needs according to their current business and product development stage.

Submit proposals for lightweight CFRP parts that improve performance, fuel efficiency or process efficiency as well as parts that increase the range of electric vehicles or improve human wellbeing.

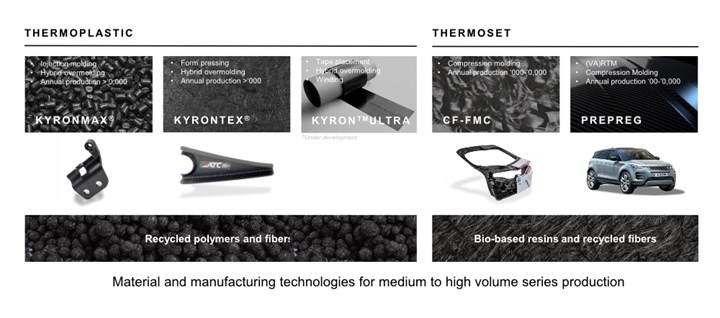

Parts from carbon reinforced lightweight materials are often produced via manual dry or wet layup, which is the simplest and oldest way to produce composite parts. The process results in a part with limited performance and repeatability and the process itself requires long cycle times, is relatively labor intensive and therefore costly to scale.

MCG Advanced Materials Division produces manufacturing solutions for the cost-effective production of carbon fiber parts at high volumes, including solutions for thermoset prepreg compression molding, carbon fiber sheet molding (CF-SMC/FMC), thermoplastic organofleece (KyronTEX®) and sandwich panels (KyronTEX®), and injection molding of carbon-fiber-reinforced thermoplastic (KyronMAX®).

For the challenge, we are asking startups, scaleups and universities to submit proposals for lightweight CFRP parts that improve performance, fuel efficiency or process efficiency (robotics, rotational parts, etc.), as well as parts that increase the range of electric vehicles (autonomous delivery vehicles, UAV, etc.) or improve human wellbeing (e.g.: wheelchairs or bionics).

Experts will support participants as they navigate through the toolbox.

Valuable Access Before, During, and After

The ambition is to unlock the full potential of modern composite material and production technologies that are now available at scale. To accomplish this, winners will have access to technology resources, as well as support in material selection, tool design, scalability and design for manufacturing. In addition, the winners will get access to industry experts, MCG’s CVC arm, and the wider network to create global exposure.

The grand prize winner – selected by the jury – will have access to $25,000 worth of support from MCG, in addition to global recognition for their product. The company will also hand out the Innovation Award for the most impactful, differentiated, innovative idea, which comes with support worth $10,000. Finally, the Wevolver community winner will receive an honorable recognition.

Key Dates

| Launch | October 24, 2022 |

| Composite Challenge Webinar | November 17 |

| Early Bird Close | November 30 |

| Challenge Close | January 22, 2023 |

| Wevolver Community Vote | January 22 – February 1 |

| Finalists Announced | February 1 |

| Winners Announcement | February 21 |

Selecting a Winner

The process for determining the winner will focus on four major criteria: Technical Feasibility, Scalability, Commercial Feasibility and Sustainability. To help facilitate judging, participants are encouraged to beta test parts with potential customers using minimum viable products or other prototypes.

Our jury consists of senior leaders and global experts from Mitsubishi Chemical Group (MCG), universities and the industry, representing various fields of expertise (bio-based polymers, carbon fiber, 3D printing, aerospace, composite part manufacturing, venture capital, market intelligence, lean six sigma, digital marketing, business models, etc.).

Technical Feasibility is assessed by a group of technical experts using the Technical Readiness Level (TRL). The TRL assesses readiness through basic research, all the way through testing, prototyping and proving functionality. Teams that can show customer testing or have entered in commercial sales (of beta versions or beyond) are favored, as it increases their readiness level.

Similarly, Scalability is being rated according to the Manufacturing Readiness Level (MRL). Like the TRL, the MRL assesses manufacturability through numerous levels of development ranging from conceptualizing possible challenges to developing a full manufacturing line. In addition to MRL, judges will assess the team dedicated to scaling up production, an important aspect of executing plans to develop a product.

Commercial Feasibility depends largely on the business model of the contestant. Often the commercial viability of a part is tied to the uniqueness or its differentiation from what already exists in the market. Judges will also look at how radical the solution is, how widely applicable it is, and the global reach. Judges will look at the entire business model, with transactional, service-based and circular business models (or elements thereof) all welcomed.

Sustainability is a large playing field and is considered as one of the main judging criteria. This may include solutions that are good for the well-being of our society (for example assistive technologies, like wheelchairs and prosthetics), reducing waste, design for recycling, reducing energy during production, improving fuel efficiency by lightweighting or friction reduction, extending the lifetime of a product, or promoting circular economy.

We are calling upon all innovators, entrepreneurs, startups and scaleups to submit their big idea to the Composite Engineering Challenge to take a step towards unlocking the full potential of your product.

CALL FOR ENTRIES

Composite Engineering Challenge

For more information or to submit your entry, visit growthgarage.mcam.com

Accepting entries until December 31, 2022

Know someone up to the challenge? Use sharing links above.