CAMX 2018 preview: Westmoreland Mechanical

Westmoreland Mechanical Testing & Research (Youngstown, PA, US) is emphasizing its non-metallic and composite materials testing capabilities.

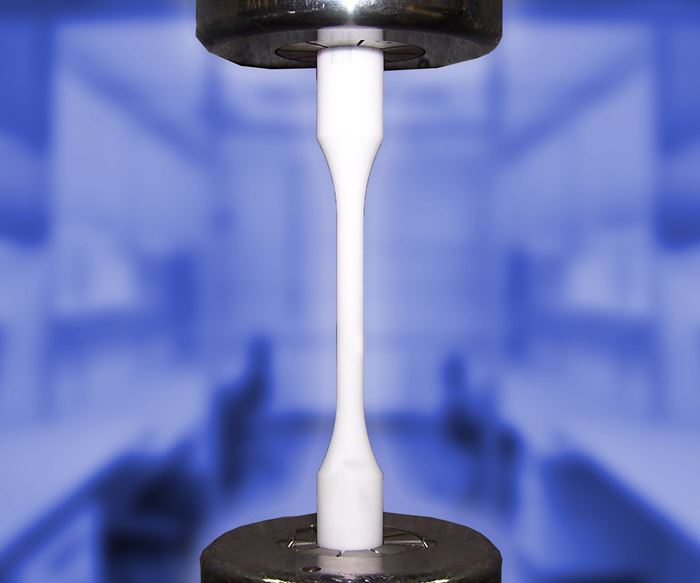

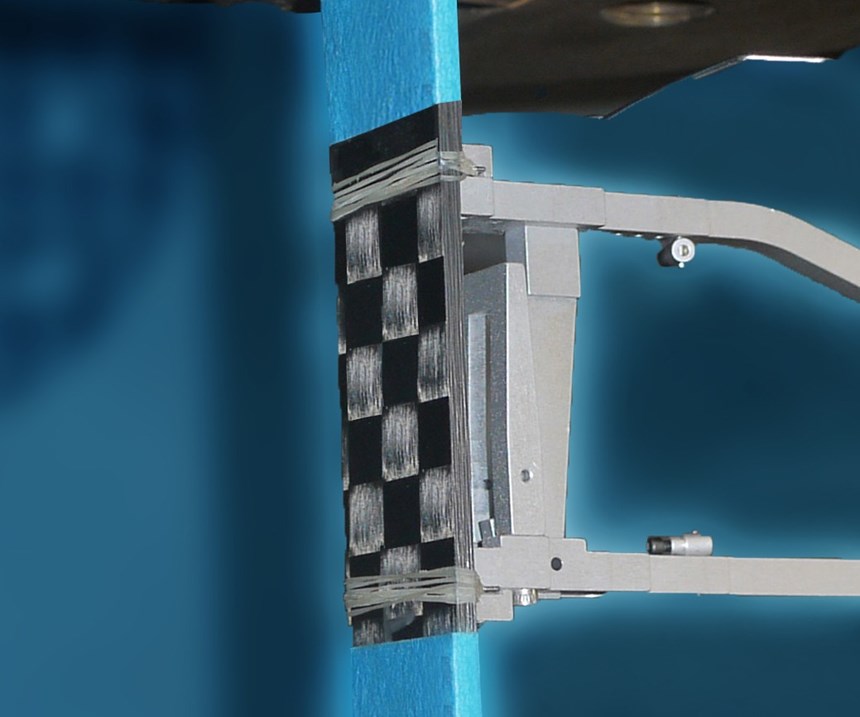

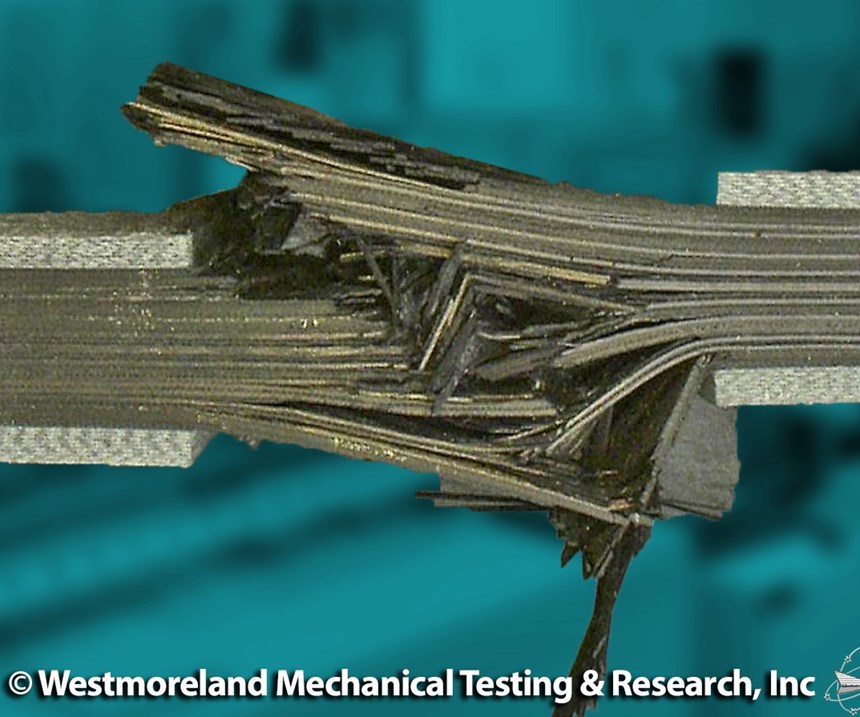

Westmoreland Mechanical Testing & Research (Youngstown, PA, US) is emphasizing its non-metallic and composite materials testing capabilities. Its comprehensive testing is said to provide the testing intelligence needed for companies to make material choices that reduce production costs and material weight, and increase durability, functionality and strength. The company’s non-metallic and composites facility is equipped with an array of hydraulic, electro-mechanical, drop tower/pendulum impact test frames, and includes a full chemistry lab for conducting tests such as density and fiber content tests using resin burn-off and acid digestion methods. The facility also features a dedicated machine shop for accommodating unusual dimensions and geometries. The facility’s 3D optical deformation analysis and thermal analysis testing includes dynamic mechanical analysis (DMA), thermomechanical analysis (TMA), differential scanning calorimetry (DSC) and thermogravimetry (TGA). In addition to standardized tests, the company also offers testing to individual customer specifications. Booth BB4.

Related Content

-

Materials & Processes: Composites fibers and resins

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

-

CAMX 2022 exhibit preview: Scott Bader

Scott Bader North America showcases its Crestabond and Crestomer structural adhesives, Crestafix bonding pastes, Crestapol urethane acrylate resins and Crestamould tooling systems.

-

What to expect at CAMX 2023

Are you ready for Composites and Advanced Materials Expo (CAMX) 2023? This year’s event takes place Oct. 30-Nov. 2, 2023 in Atlanta, Ga., U.S.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)